A type fire extinguishing agent, and its preparation method and application method

A fire extinguishing agent, polyacrylamide technology, applied in fire protection equipment and other directions, can solve the problems of unsuitability for large-scale popularization and application, high production cost, waste of water resources, etc., and achieves good fire extinguishing performance, convenient storage, and less consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

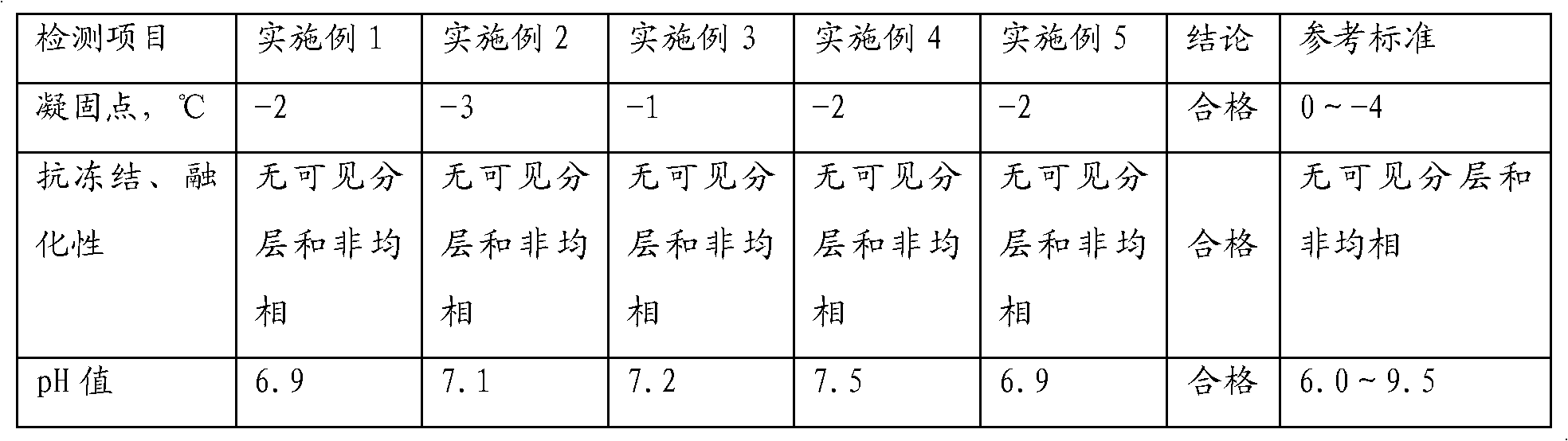

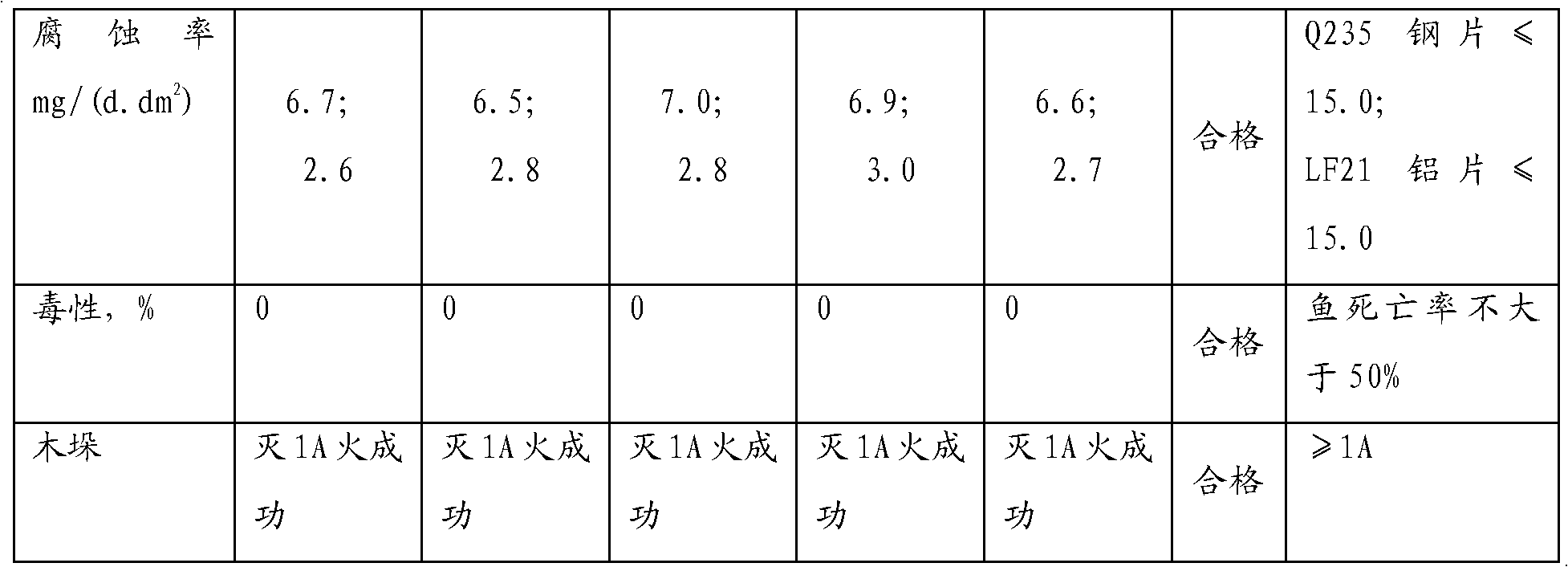

Examples

preparation example Construction

[0042] The preparation method of the above-mentioned type A fire extinguishing agent is as follows: first mix the two raw materials polyacrylamide and xanthan gum, then add into water and stir to dissolve completely.

[0043] Among them, the raw material polyacrylamide is produced by Beijing Jiaruilin Water Treatment Technology Co., Ltd., polyacrylamide with a molecular weight of 4 to 18 million; xanthan gum is produced by Hebei Dadi Biotechnology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com