Real time monitoring method for resin rheological property under action of ultrasound, and apparatus thereof

A technology for real-time monitoring of rheological properties, applied in measurement devices, flow characteristics, instruments, etc., can solve problems such as affecting the rheological properties of resin, slow circulation flow, test data errors, etc., to achieve real-time testing, avoid errors, Achieving Consistent Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

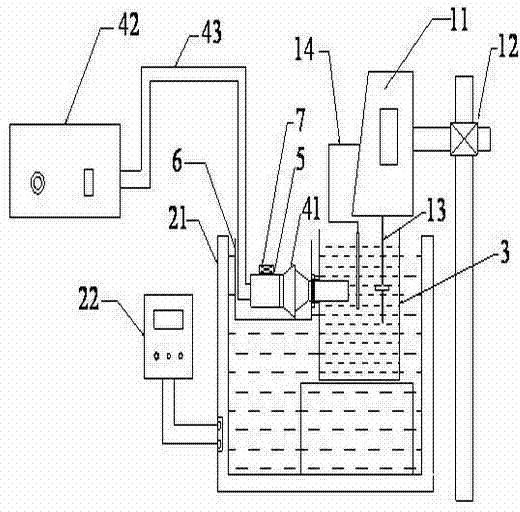

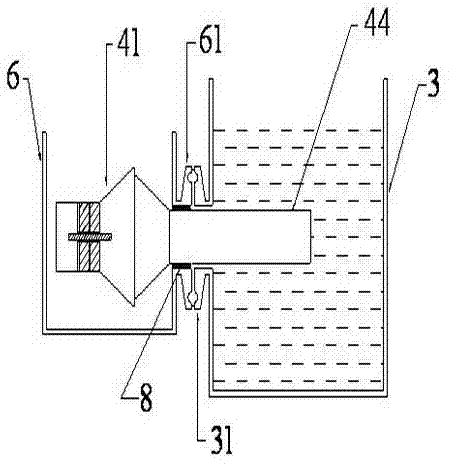

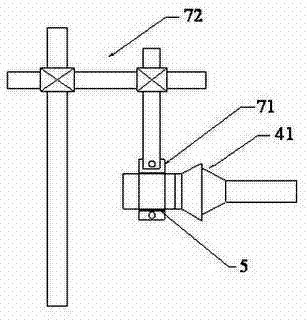

[0033] This embodiment adopts the monitoring device of the present invention (see figure 1 ), real-time testing of resin rheological properties while ultrasonically treating the resin. Its parameters are as follows:

[0034] The output power of the ultrasonic generator 42 is respectively 1200W, 1400W and 1600W; the vibration frequency of the ultrasonic transducer 41 is 20KHz; the ultrasonic amplitude is respectively 23 μm, 28 μm and 33 μm; The program is adjusted to achieve constant temperature measurement at 28°C; the resin used in the experiment is: JL-237 epoxy resin produced by Changshu Jiafa Chemical Co., Ltd. The specific test method is as follows:

[0035] (1) Preparation work before the test, put the resin to be tested into the resin container 3, connect the ultrasonic device and the viscosity tester 11, and zero-adjust the viscosity tester 11; (2) temperature control, open the oil bath The power supply heats the resin in the resin container 3, and through the adju...

Embodiment 2

[0038] The resin used in the experiment of this embodiment is 86# epoxy resin, and the test temperature of the resin is 50° C., and the remainder is the same as in Example 1.

[0039] The test results are as follows: when the ultrasonic amplitude is 23um, the resin in the resin container has circulation around the horn, and some cavitation bubbles can be observed to form and collapse, and the viscosity of the untreated resin is reduced by about 43%; when the ultrasonic amplitude is 28um , the resin in the resin container has obvious circulation around the horn, and the generation and collapse of many cavitation bubbles can be observed, and the viscosity of the untreated resin is reduced by about 39%; when the ultrasonic amplitude is 33um, the resin in the resin container becomes The rod has obvious circulation phenomenon, and the generation and collapse of a large number of cavitation bubbles can be observed, and the viscosity of the untreated resin is reduced by about 48%.

Embodiment 3

[0041] This embodiment adopts the monitoring device of the present invention (see figure 1 ), real-time monitoring of the rheological properties of the resin while ultrasonically treating the resin, its parameters are as follows:

[0042] The output power of the ultrasonic power supply 42 is 1400W; the vibration frequency of the ultrasonic transducer 41 is 20KHz; Constant temperature measurement under different temperature conditions; the resin used in the experiment is 86# epoxy resin. The specific test method is as follows:

[0043] (1)-(2) are the same as embodiment 1. (3) The test of viscosity, by observing the resin temperature displayed in real time by the temperature tester, when the resin temperature reaches 28°C, open the ultrasonic generator 42 and start to perform ultrasonic action on the resin and adjust its output power to be 1400W (at this time, ultrasonic The amplitude is 28 μm), and at the same time, the control program of the viscosity tester is turned on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com