Cell cover cap combination and cylindrical secondary cell

A secondary battery and battery cover technology, which is applied to secondary batteries, battery components, circuits, etc., can solve the problems of increasing the zero potential of positive and negative windings, breakage, etc., and achieve good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

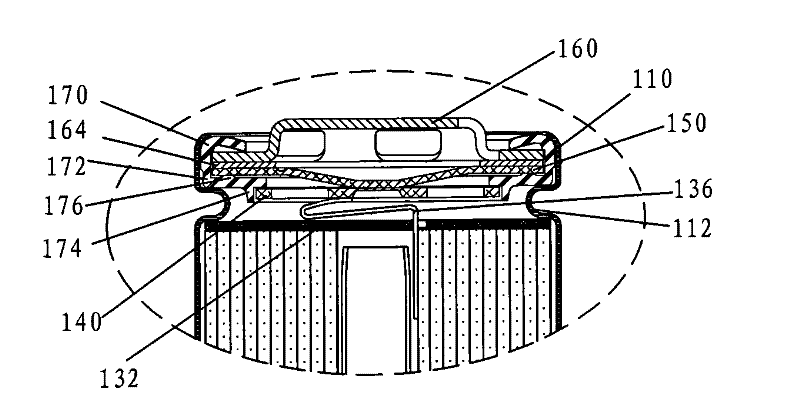

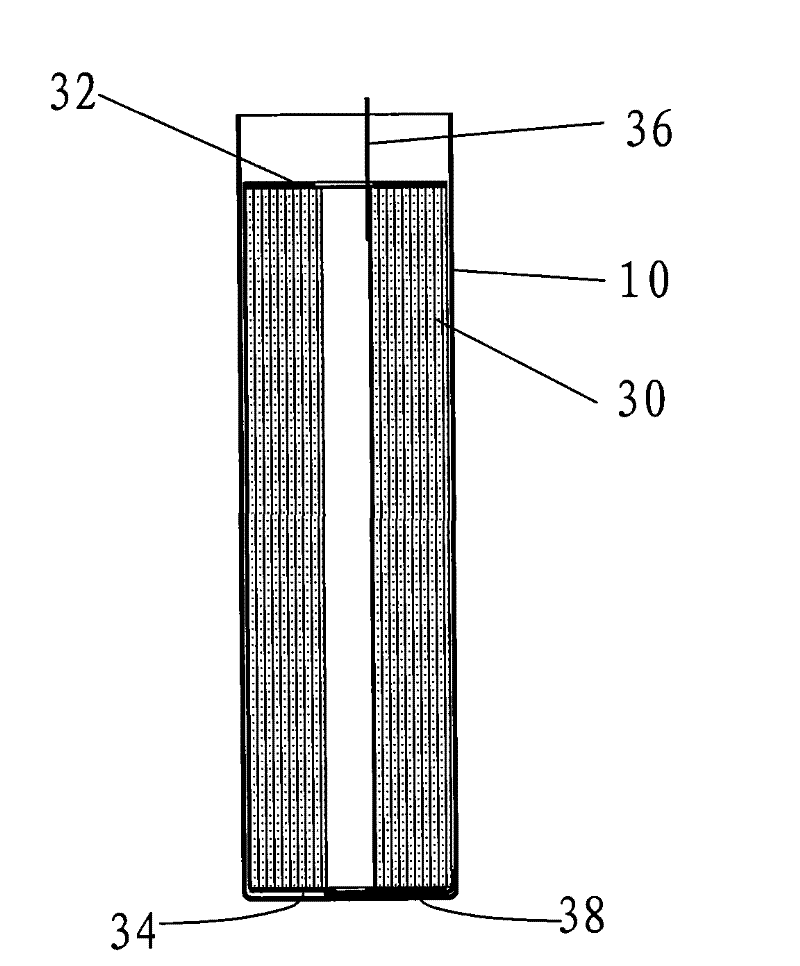

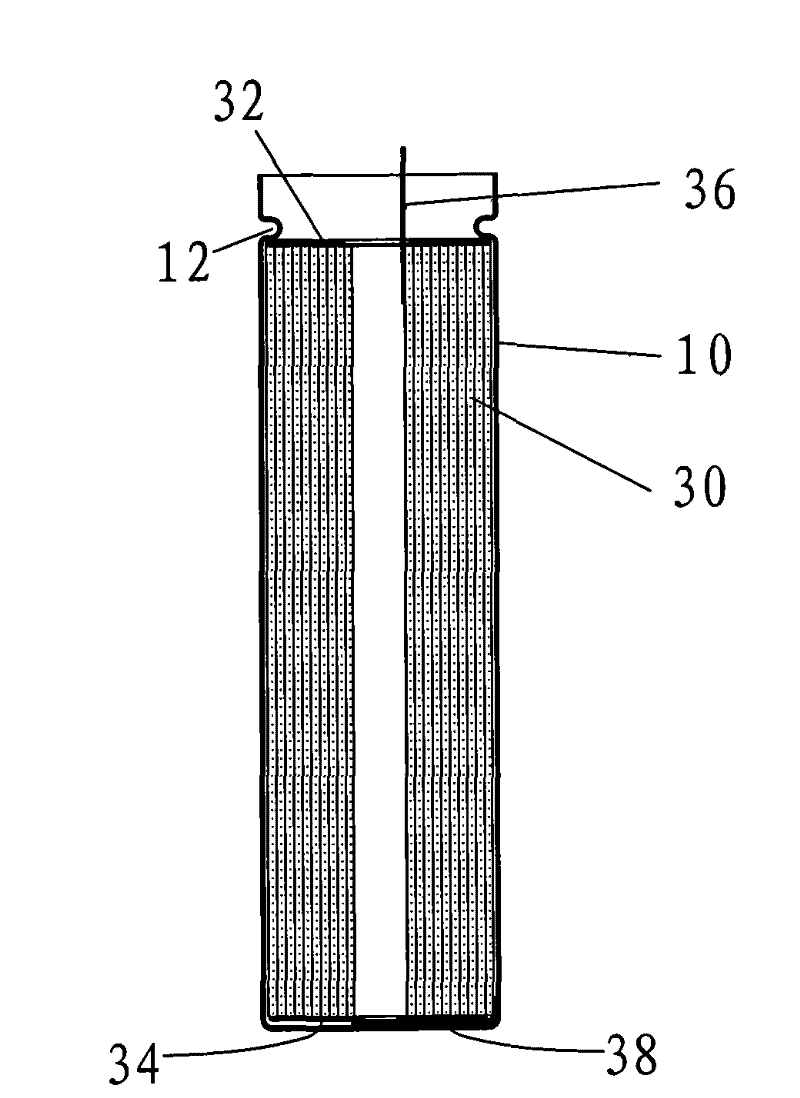

[0023] see Figure 2 to Figure 5 , this embodiment relates to a cylindrical secondary battery, including a casing 10 , positive and negative windings 30 and a combination of caps. The cap assembly includes a sealing sleeve 70 , a base plate 40 , a pressure protection device 50 and an electrode lead-out end 60 . In this embodiment, the sealing sleeve 70 is provided to support the first boss 75 of the pressure protection device 50 and the electrode lead-out end 60, and the second boss 72 is arranged below the first boss 75 to support the substrate 40. An elastic isolation ring 71 is laid between the pressure protection device 50 and the substrate 40, and the upper and lower positions of the elastic isolation ring 71 and the second boss 72 are restricted, so that the pressing and sealing operation of the battery on the first boss has a positive impact on the substrate 40. The influence of the battery is restricted, thereby effectively avoiding the problem of zero potential of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com