Cooling device for diameter measuring instrument

A technology of cooling device and caliper, which is applied in the direction of length measuring device, metal processing equipment, metal rolling, etc., can solve the problem that there is no reliable cooling device, the detection reliability and equipment stability of the caliper are difficult to guarantee, and the detection accuracy is difficult. Guarantee and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

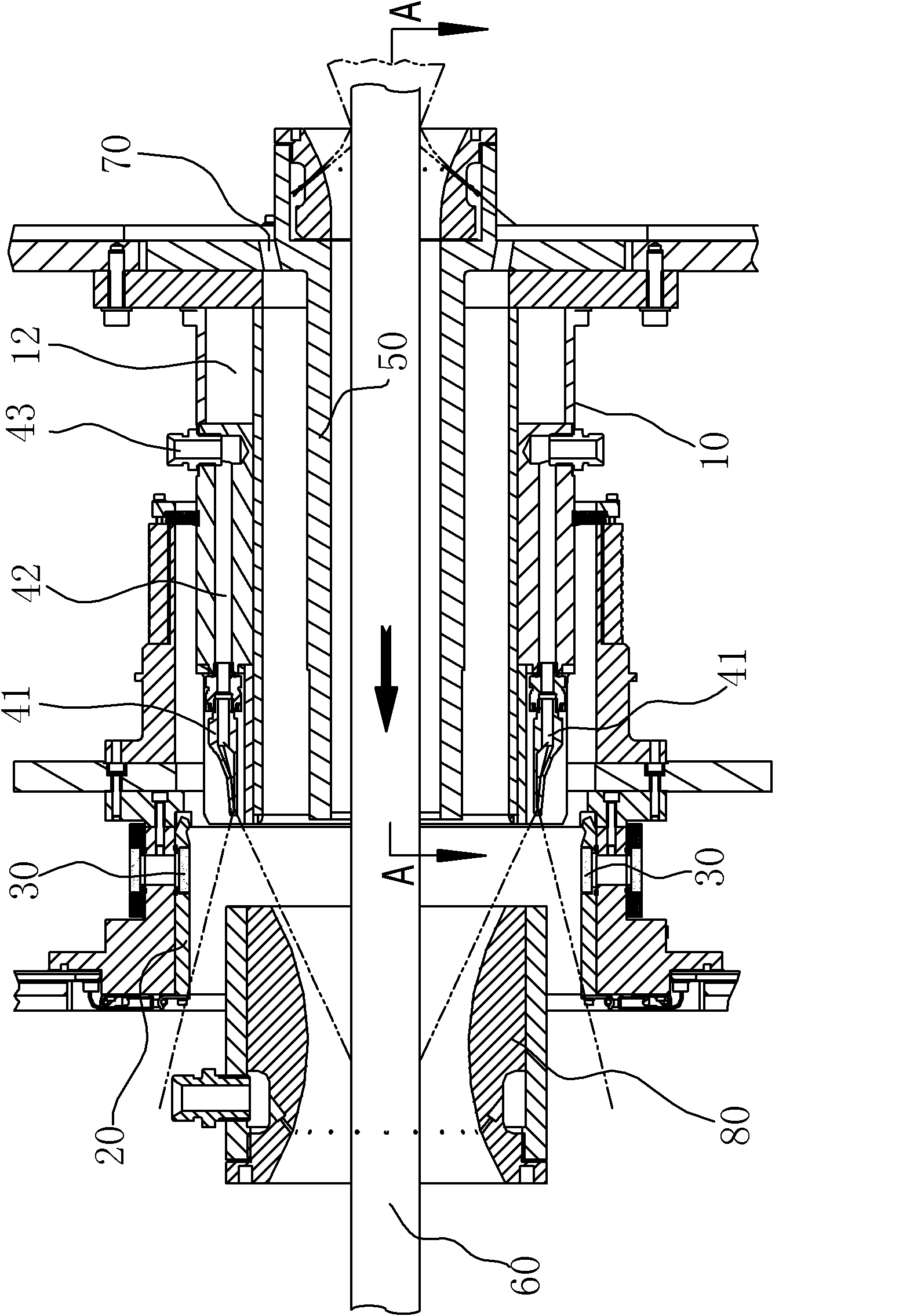

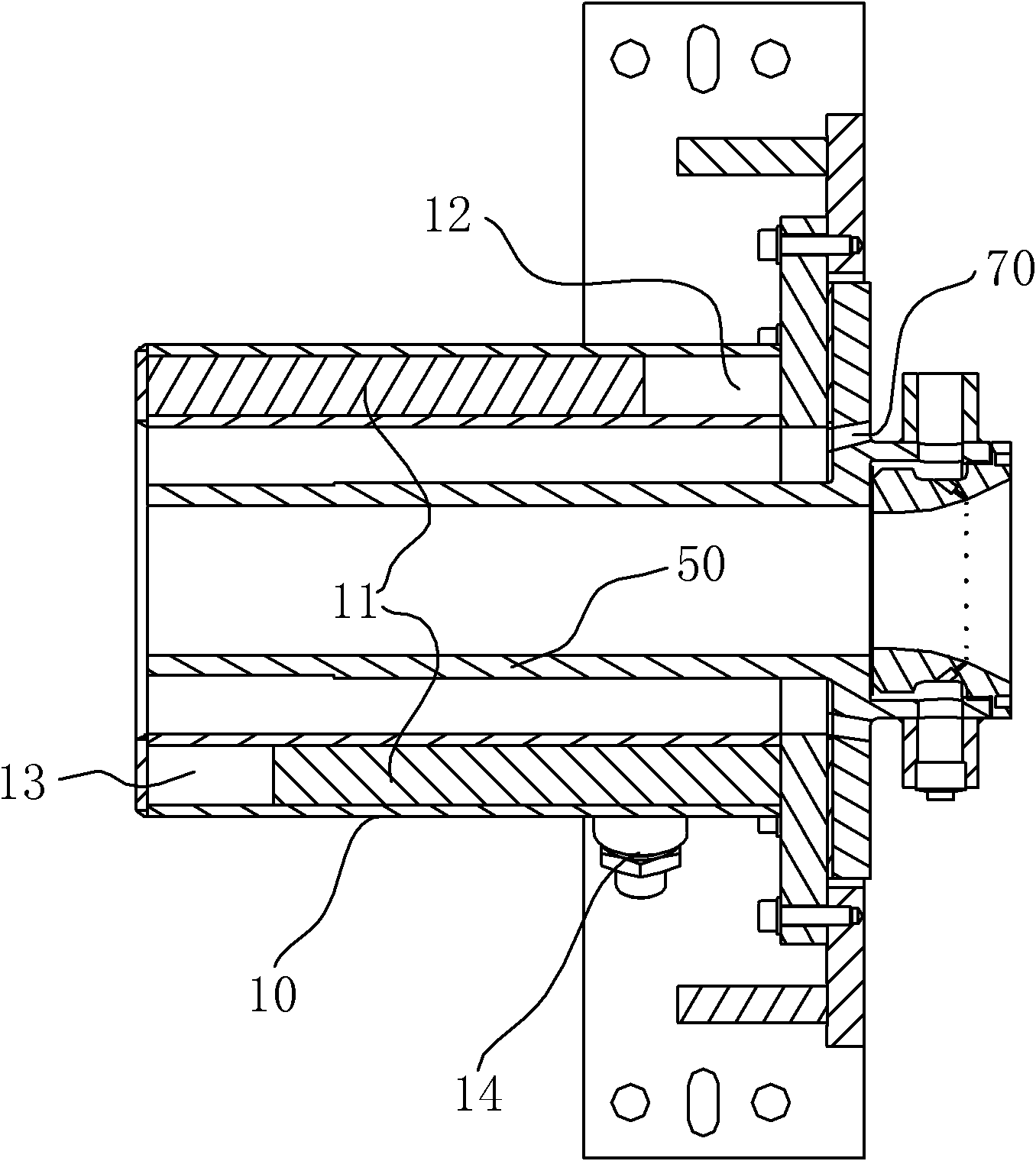

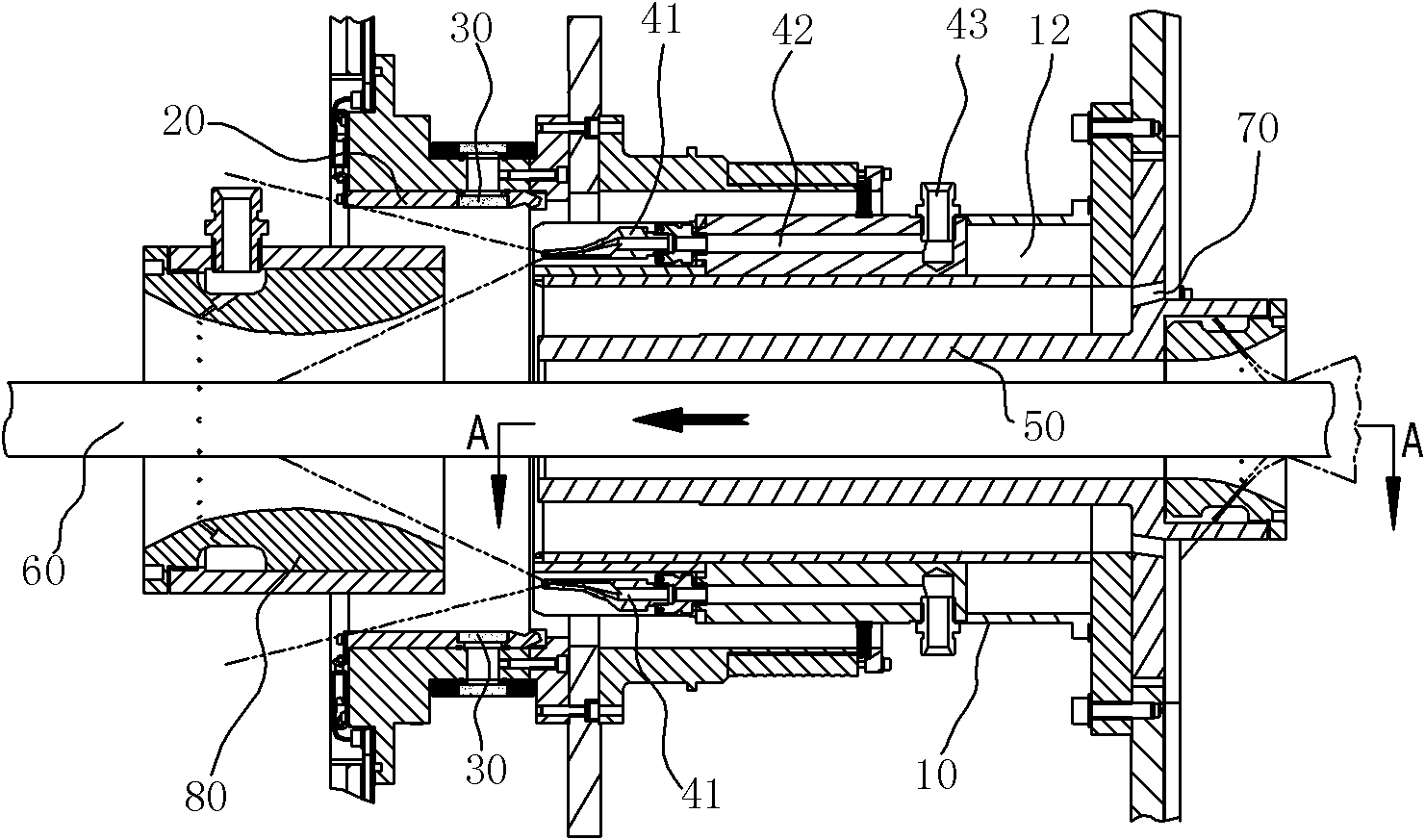

[0009] Such as figure 1 , 2 The shown cooling device of a caliper includes a circulating cooling water mechanism and a blowing mechanism arranged in the area of the caliper where the wire 60 to be inspected passes.

[0010] The cooling water mechanism can be the structure of the coil pipe arranged along the area, or the structure with cooling water in the interlayer; as long as the blowing mechanism can accelerate the flow of the airflow, it can be used. When the blowing mechanism works, the blown air will increase. Due to the pressure in the traveling area of the large wire rod 60, the airflow naturally flows to the outside of the caliper, so that the heat of the wire 60 is discharged from the caliper to cool down the caliper, which is the air cooling mechanism; circulating cooling water The mechanism also acts as a thermal barrier, preventing the heat from the wire from being transmitted to the caliper. In this way, after double cooling and heat insulation by air cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com