Sealing device for diameter gauge

A technology of sealing device and caliper, which is applied in the field of sealing device and cleaning, can solve the problems of high cost, high temperature, complex structure, etc., and achieve the effect of reducing device cost, processing cost and reliable cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

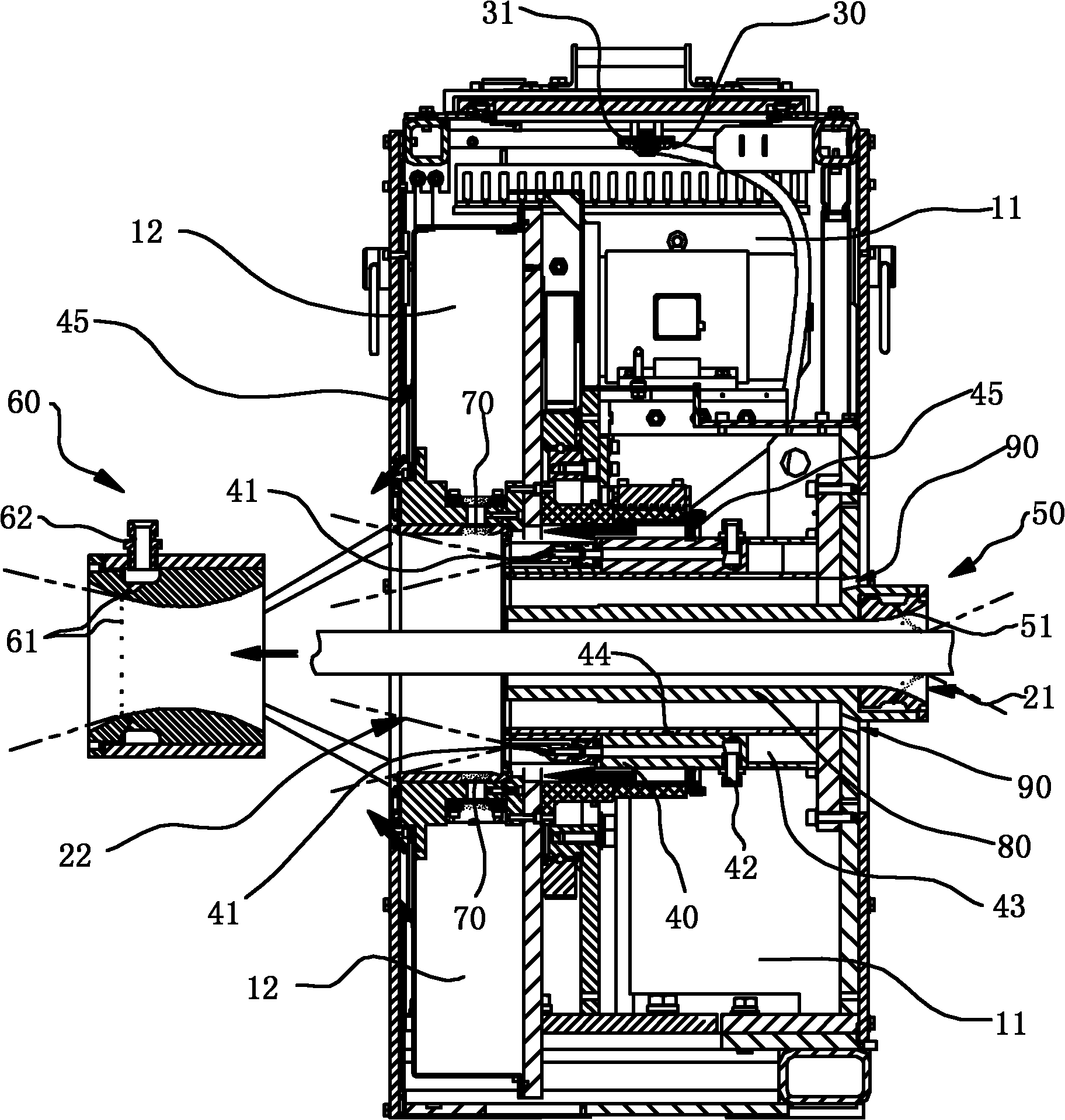

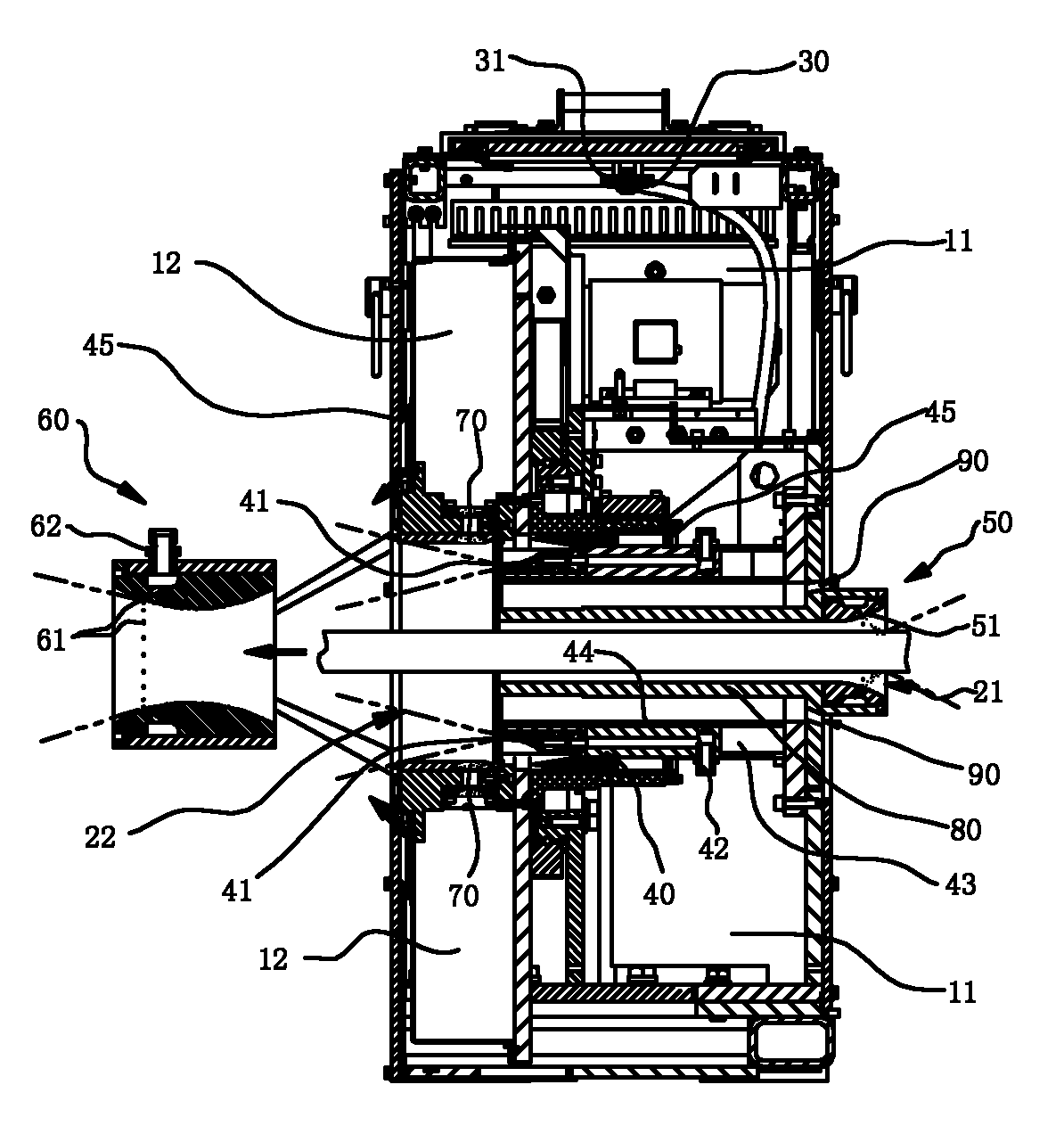

[0008] A sealing device for a caliper, including an inflating mechanism 30 for inflating the inner chambers 11 and 12 of the caliper, the gas source of the inflating mechanism 30 is clean gas, and the inflated gas is provided by the slit on the caliper and / or or pore discharge. That is to say, the caliper does not need to set gaskets or sealing rings or sheets between the parts that cooperate with each other to achieve sealing, or only use the existing sealing structure in some parts with simple structure and easy to use standard seals. Instead, an inflation mechanism 30 is provided on the caliper, that is, a mechanism for pressurizing the inner chamber 11 of the caliper to generate positive pressure in the inner chamber of the caliper.

[0009] When the inflation mechanism 30 inflates the inner cavity 11 of the equipment, the air pressure in the inner cavity 11 of the caliper must increase, so that the fresh clean gas supplemented by the inflation mechanism 30 will naturally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com