Suspension type self-balancing demoulding device

A demoulding device and self-balancing technology, which is applied in the field of demoulding devices of multi-station building material static pressure forming equipment, can solve problems such as eccentric load of turntable, difficulty in rotation, and influence on normal production of equipment, so as to achieve the effect of ensuring high-speed production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

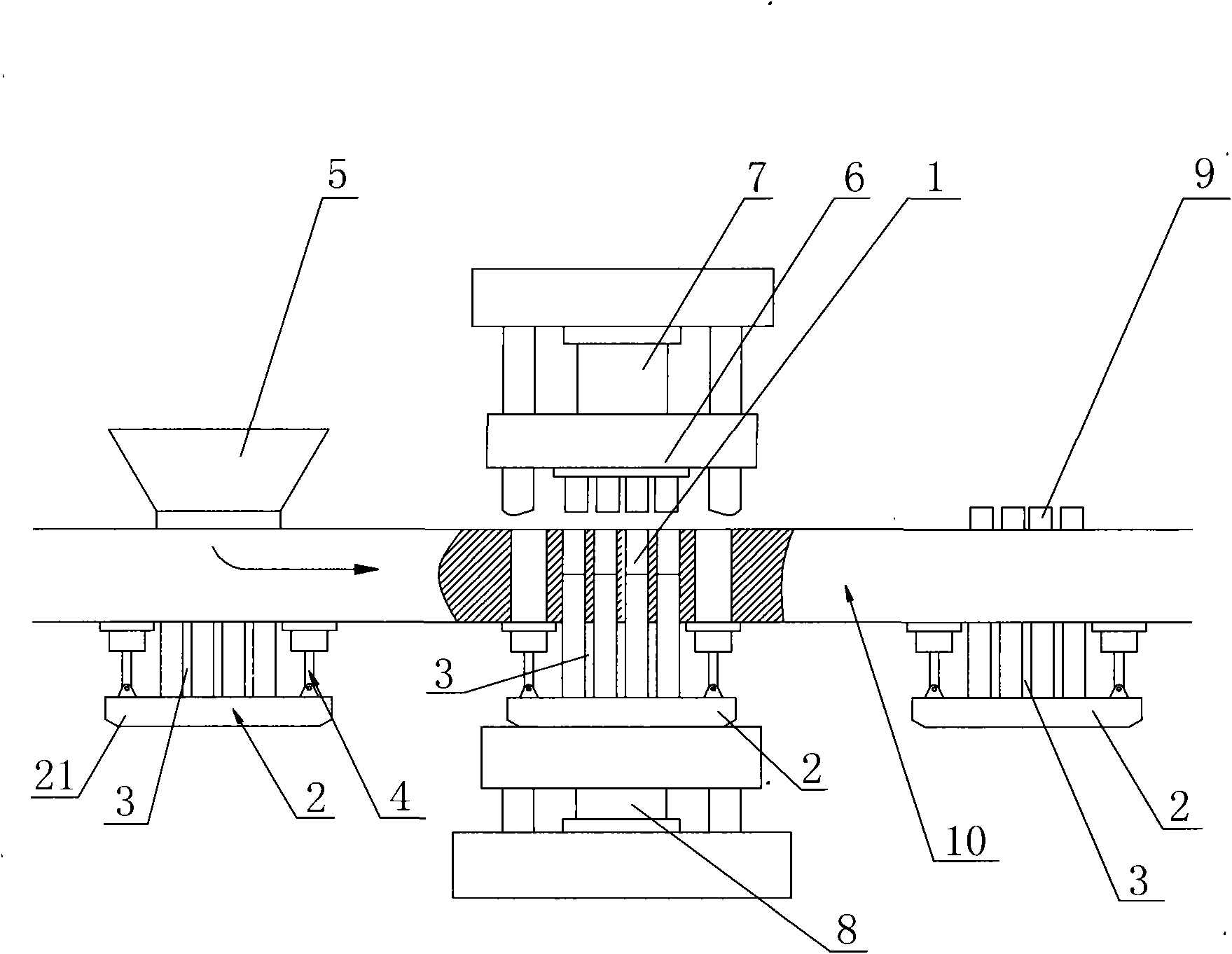

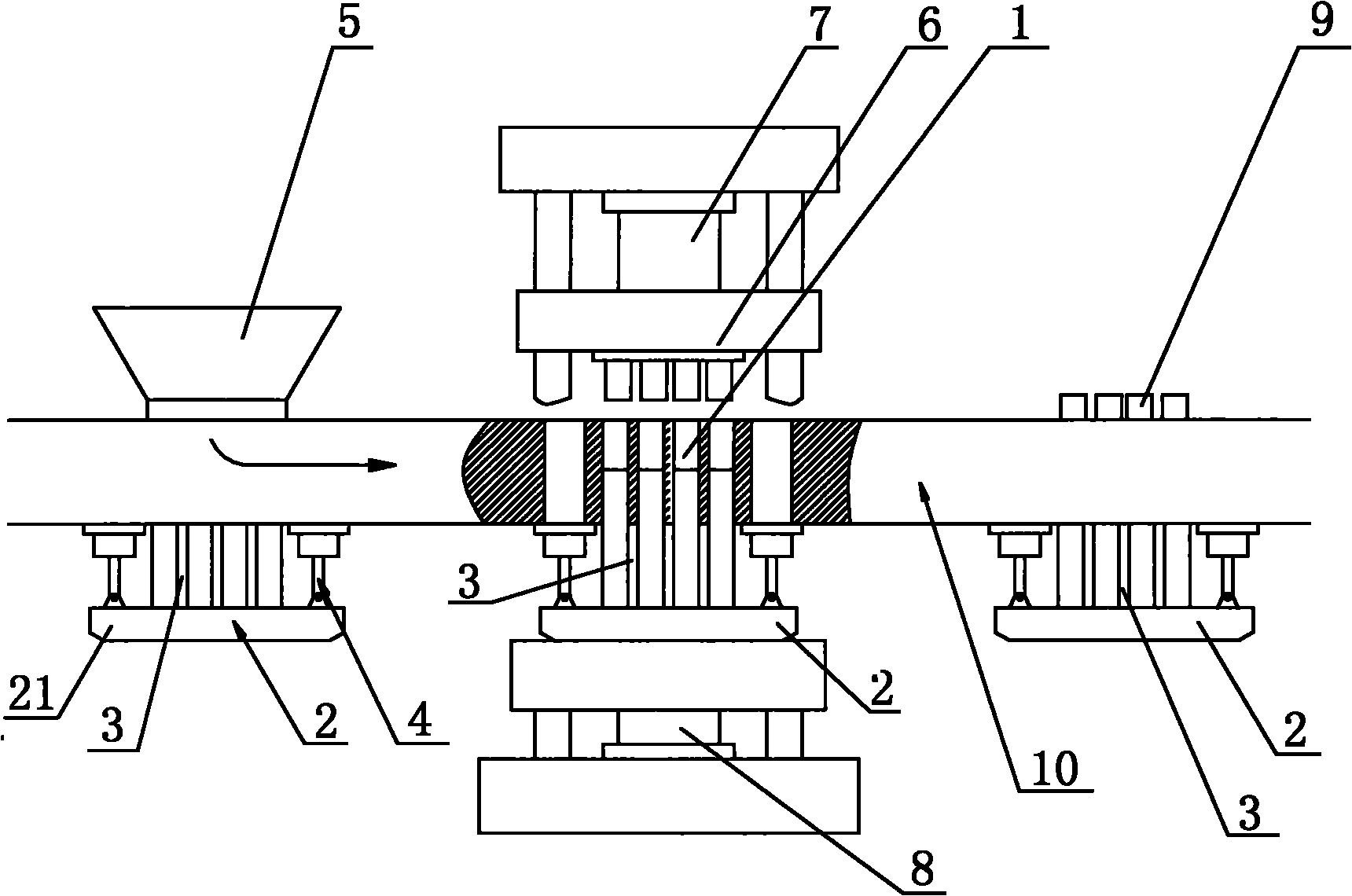

[0016] Embodiment: a suspended self-balancing demoulding device, including a mold frame 1 and a lower mold 2, the mold frame 1 is embedded on a rotary mold frame seat (turntable) 10, and the mold frame seat 10 is horizontally arranged , the lower mold 2 can be longitudinally positioned and moved in the mold frame 1, and several tappets 3 arranged at intervals are in the mold cavity of the mold frame 1, and the lower mold 2 is composed of tappets 3 and lower mold crossbeams 21. The lower end of the column 3 is fixedly installed on the lower mold beam 21 (moves up and down with the lower mold beam), and there are even numbers of demoulding cylinders 4, and the cylinder bodies of the even number of demoulding cylinders 4 are fixed (embedded) outside the mold frame On the mold frame seat 10 of the side, the head of the cylinder rod (i.e. the piston) of the demoulding cylinder 4 is downward, and the head of the cylinder rod is fixed to suspend the lower mold crossbeam, and the even-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com