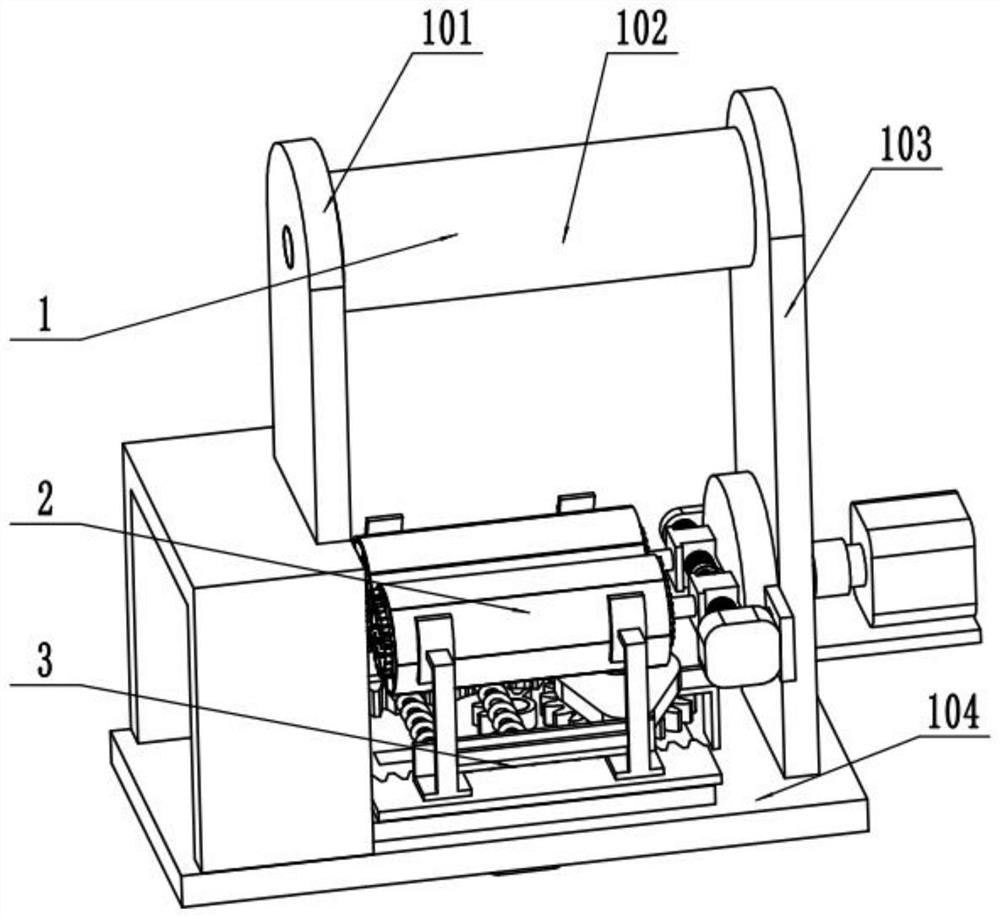

Textile quality detection algorithm and apparatus based on visual identification technology

A visual recognition and detection algorithm technology, applied in the field of visual recognition, can solve problems such as poor product quality and corporate reputation, high missed detection rate, and impact, and achieve the effect of ensuring high-speed production process, ingenious cooperation, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

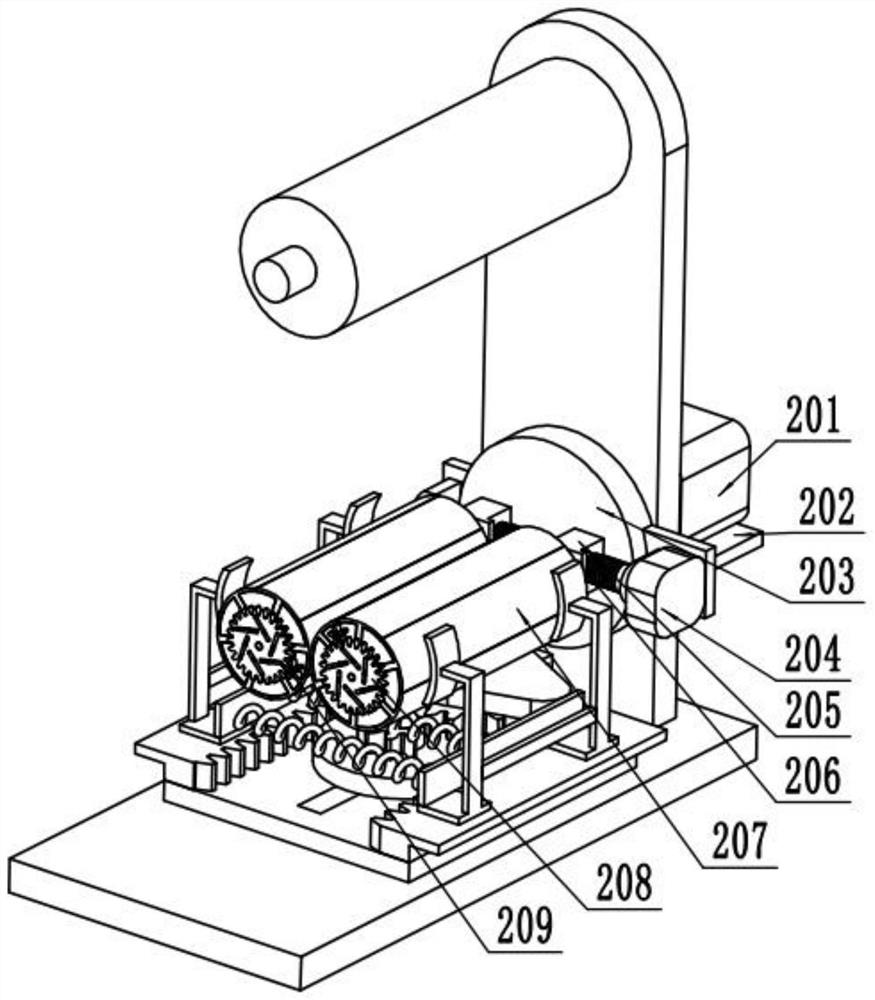

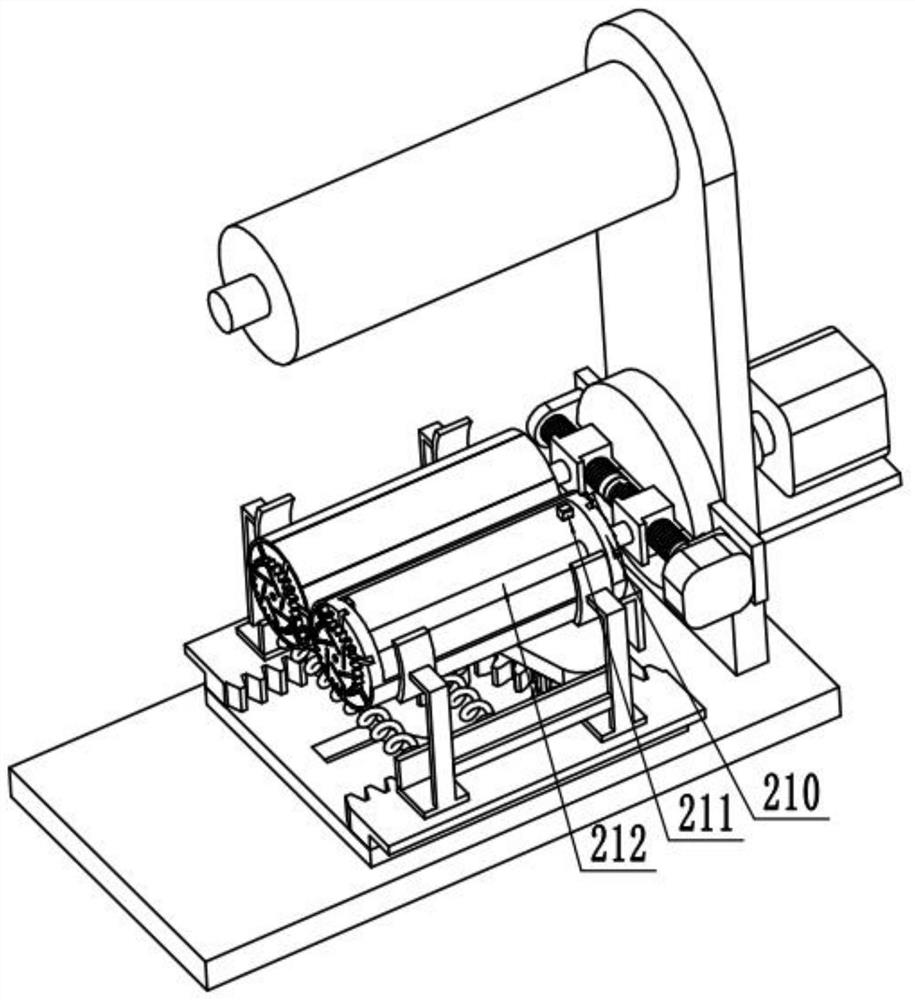

[0038] A textile quality detection algorithm based on visual recognition technology. The textile quality detection algorithm based on visual recognition technology uses a regional convolutional neural network, including an input layer, a convolutional layer, a downsampling layer, a fully connected layer, and an output layer. The textile quality inspection algorithm based on visual recognition technology includes the following steps:

[0039] Step 1: Acquisition of the image of the textile to be detected;

[0040] Step 2: Generate target candidate regions;

[0041] Step 3: defect feature extraction;

[0042] Step 4: Identify and locate defect features;

[0043] Step Five: Find the best location information.

[0044] The way to obtain the textile image is to input the image into the regional convolutional neural network. The features extracted by the regional convolutional neural network include defect category, defect position, defect position coordinates and the size of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com