Driving mechanism of dual-motor clutch of electronic lock

A driving mechanism and dual-motor technology, which is applied in building locks, building structures, and non-mechanical transmission-operated locks, etc., can solve the problems of poor opening performance of mechanical lock resistance technology and restrict the market application of electronic locks, and achieve simple structure, Increased extra wear, reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

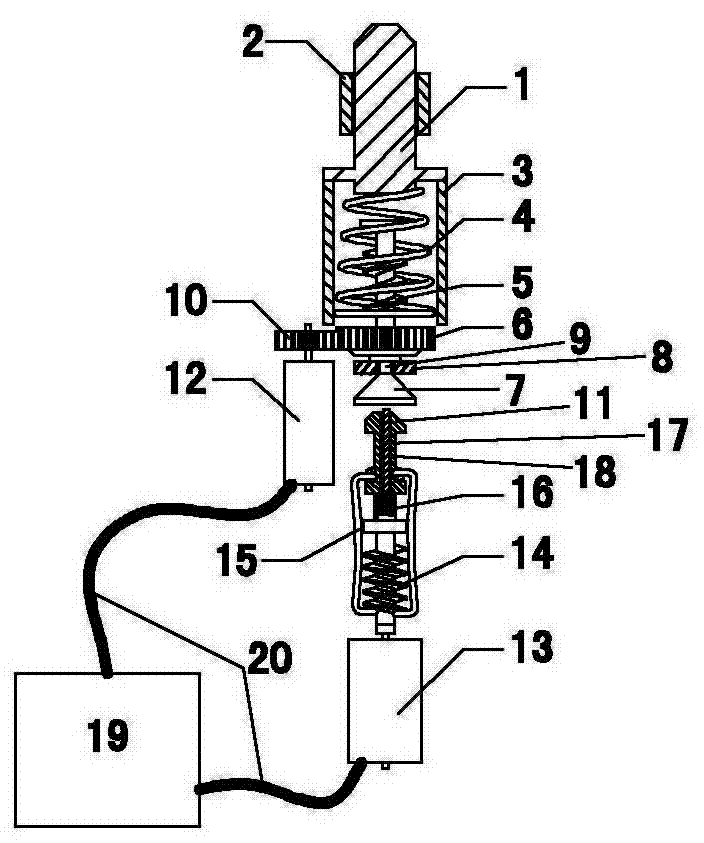

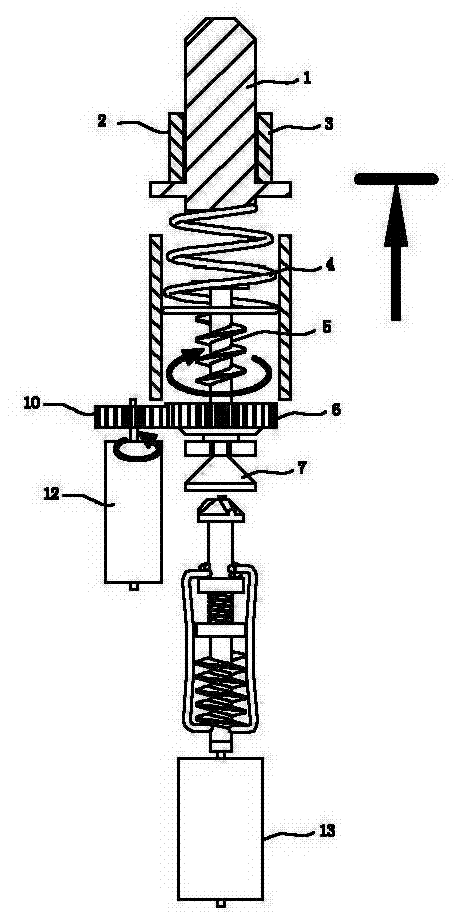

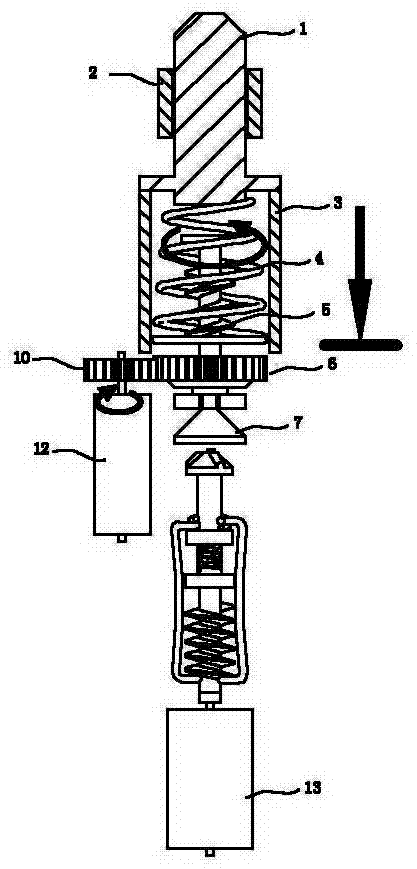

[0026] figure 1 It is a structural schematic diagram of the dual-motor clutch driving mechanism of the electronic lock of the present invention.

[0027] See figure 1 , the electronic lock dual-motor clutch drive mechanism provided by the present invention includes a drive pin 1, a guide sleeve 2, a limit stop frame 3, a drive spring 4, a drive worm 5, a first driven gear 6, a second driven Moving gear 7, bracket 8, connecting shaft 9, first driving gear 10, second driving gear 11, main motor 12, auxiliary motor 13, clutch worm 14, clutch connecting rod 15, compression spring 16, the cross section of the upper section is D A font-shaped auxiliary motor output shaft 17, a second driving gear annular chute 18, an electronic control module 19, and a transmission line 20. The first driving gear 10 is contained in the upper section of the output shaft of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com