Novel pipeline type flow deflector oil-water separator rotation starting device

An oil-water separator and deflector technology, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of complicated equipment and troublesome maintenance, avoid oil-water remixing, and improve the swirl field. The effect of improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

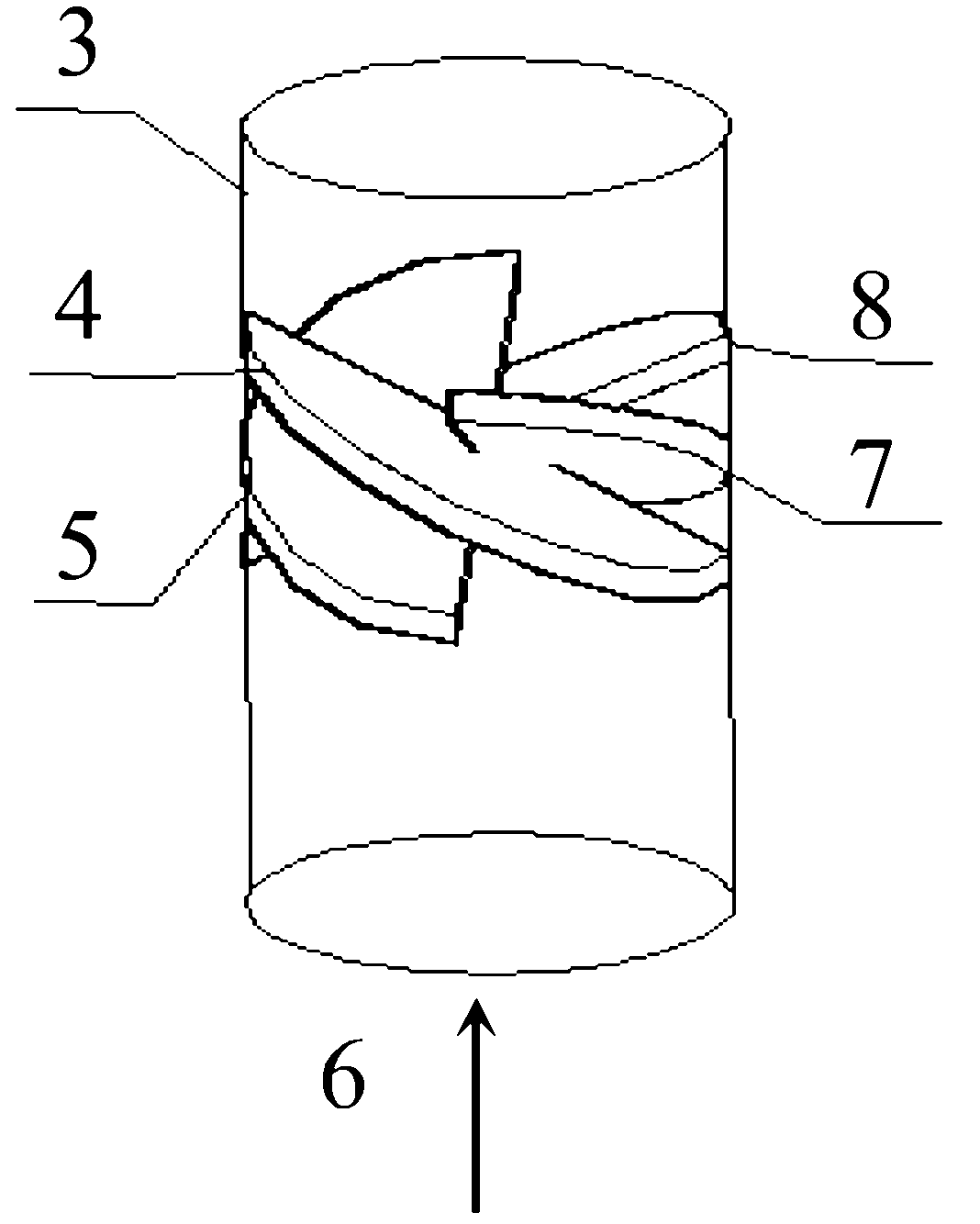

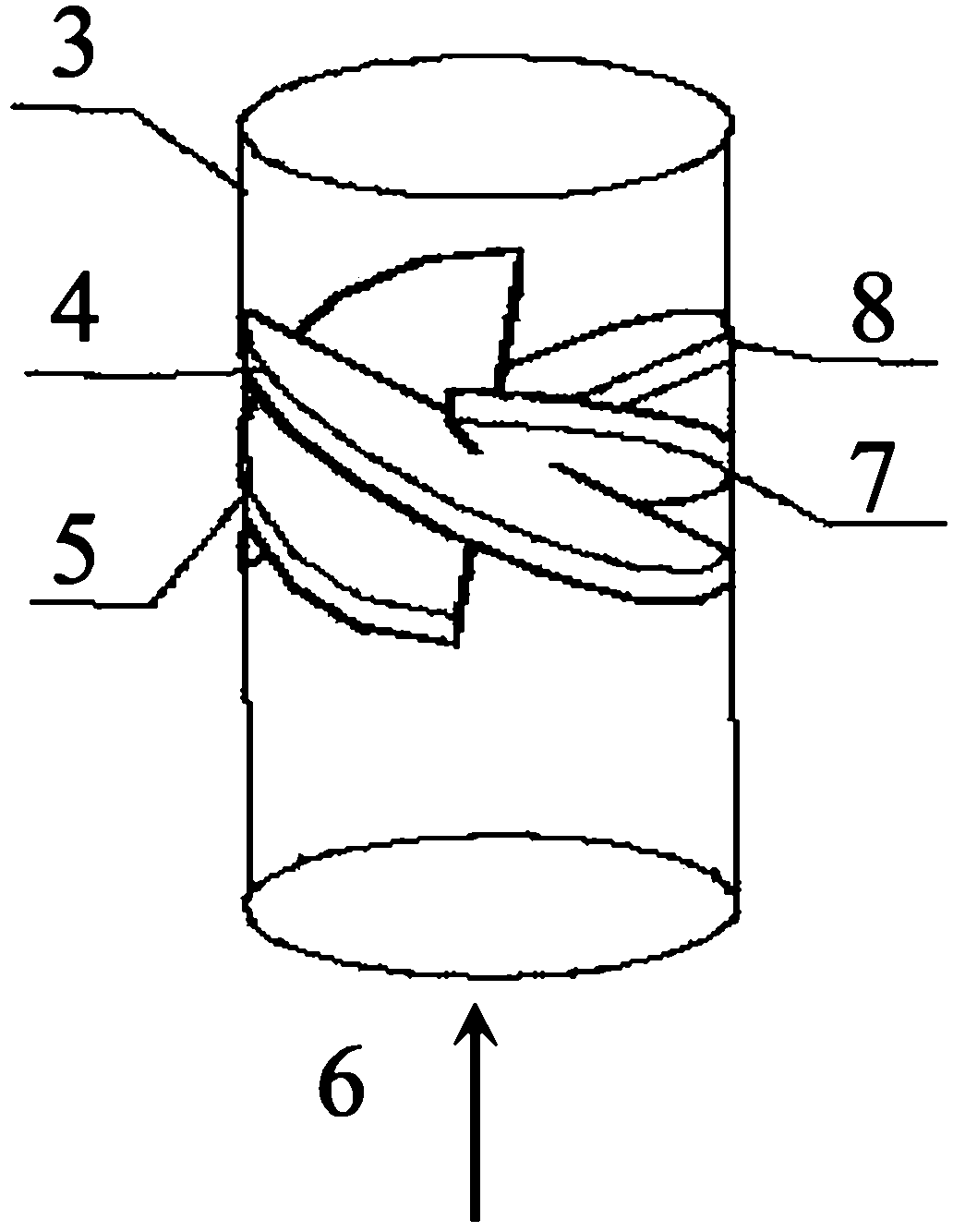

[0018] Such as figure 1 As shown, the spinning device of the present invention includes: 4 guide vanes 4, 5, 7, 8 that can be fixedly and obliquely installed in the pipeline 3, and the guide vanes 4, 5, 7, 8 are evenly distributed along the circumference of the pipeline 3, And in the axial direction of the pipeline 3 are stacked successively. When the fluid mixed with oil and water flows through the deflectors 4, 5, 7, and 8 along the flow direction 6, a center-symmetrical swirl field will be formed, in which the oil and water are separated due to different centrifugal forces due to different densities. .

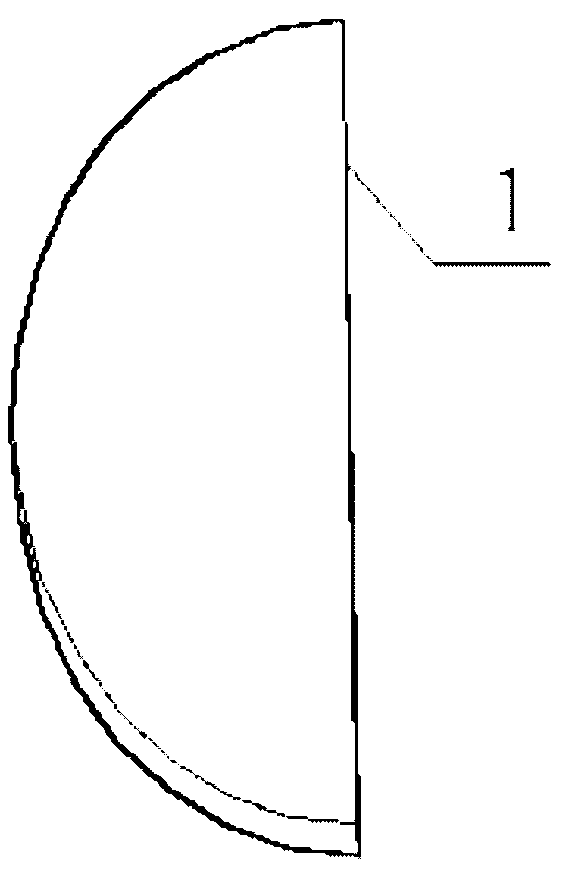

[0019] Such as figure 2 As shown, the deflectors 4, 5, 7, and 8 are made of semi-elliptical stainless steel or other wear-resistant materials, and the angle θ between the long axis of the deflectors 4, 5, 7, and the cross-section of the pipe 3 is is 45°, the short axis is parallel to the cross section of the pipe 3, that is, the angle α between the short axis and the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com