Constant-pressure liquid source device containing overflow groove in pressure container

A technology for pressure vessels and overflow tanks, which is applied in measuring devices, testing/calibrating devices, liquid/fluid solid measurement, etc., can solve the problem of poor flow stabilization accuracy of the gas-liquid container pressure stabilization method, achieve a wide range of applications, and avoid The effect of investing more

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

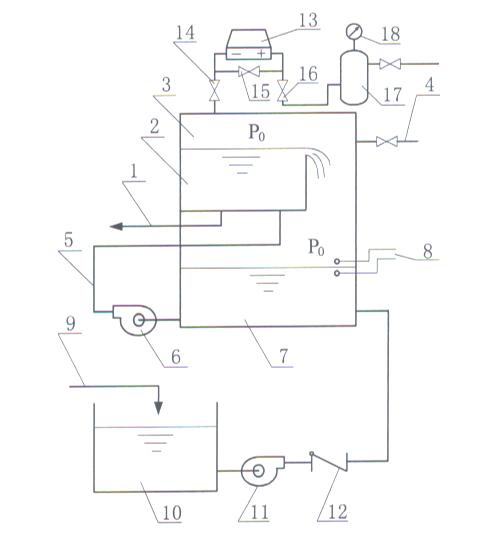

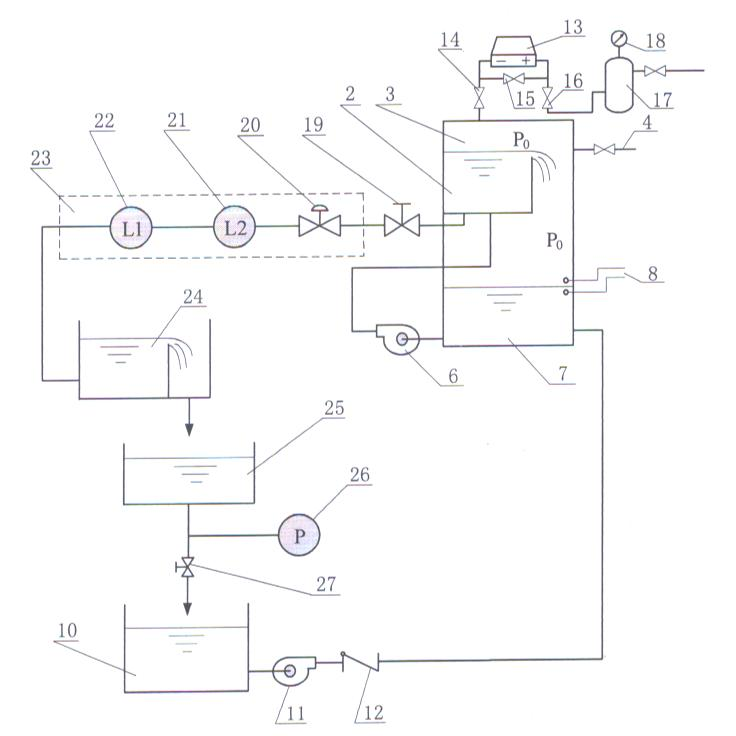

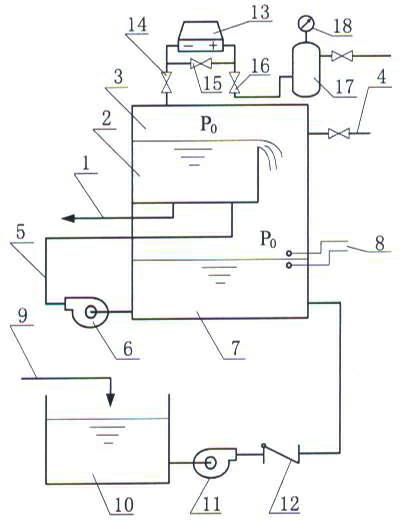

[0009] The following content is combined with the figure 1 , 2 The specific embodiment of the present invention will be further described.

[0010] exist figure 1 Among them, the pressure vessel 3 is a low-pressure vessel with a closed cylindrical structure. The pressure overflow tank 2 adopts a cylindrical structure with an upper opening, and its diameter is smaller than that of the pressure vessel 3. The two cylinders are installed on the same vertical central axis. The distance between the outer wall of the pressure overflow tank 2 and the inner wall of the pressure vessel 3 should be large enough (it is recommended to be greater than 0.1m, because the overflow of the overflow tank also flows down its outer wall), so that the annular gap between the two can ensure the pressure of the pressure vessel. 3 The air pressure of the upper part is consistent with that of the lower part. The design volume of the pressure overflow tank 2 should ensure that at the maximum flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com