Liquid flow standard calibration device

A verification device and liquid flow technology, which is applied in the field of standard verification devices, can solve the problems of front and back stroke difference, occupy a large space and floor space, and require a lot of investment, and achieve the effects of high verification accuracy, avoiding errors, and avoiding a lot of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

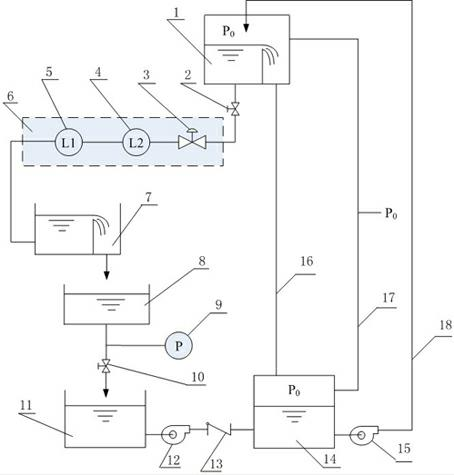

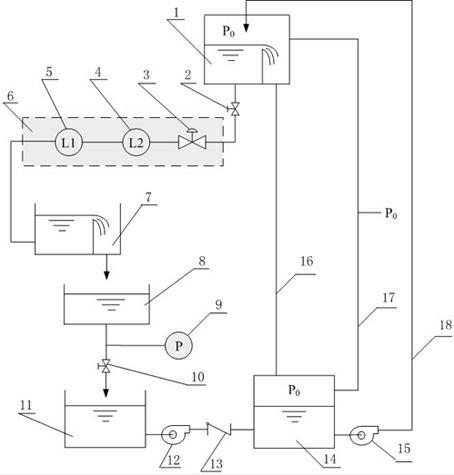

[0012] (Example 1, liquid level gauge detection mode)

[0013] exist figure 1 Among them, the working valve 2 and the verification valve 10 both adopt pneumatic shut-off valves, and a standard pressure gauge 9 is installed on the lower pipe of the standard weighing container 8. When the verification valve is closed and the liquid level in the standard weighing container rises gradually, The change of the liquid level corresponds to the pressure felt by the standard pressure gauge, and the standard pressure gauge can measure the liquid level accordingly.

[0014] The working process of this embodiment: After several verification flow points of the flowmeter 5 to be verified are input into the industrial computer in advance, the entire verification process will be automatically carried out under the control of the industrial computer. At a certain verification flow point, the industrial computer first opens the pneumatic working valve and the pneumatic verification valve, start...

Embodiment 2

[0015] (Example 2, electronic scale detection mode)

[0016] Take the standard weighing container, verification valve and connecting pipe as a whole, and let the weight of this whole act on the electronic scale. When the verification valve is closed, the electronic scale will weigh the change in weight. When the weight reaches the timing start weight Start timing, and stop timing when the weight reaches the end weight of timing. According to the weight difference at the two time points and the timing time obtained by timing, the accurate weight flow rate of the verification flow point can be calculated, and the accurate value is compared with the verification to be carried out. The output signal value corresponding to the flowmeter. An advantage of this embodiment is that weight measurements are generally more accurate than volume measurements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com