Midsize direct shear apparatus with non-lever type loading

A direct shear instrument and lever-type technology, which is used in the field of devices for testing the shear strength, stress and strain behavior of soil, the shear strength of soil and soil-rock mixtures, and the devices for testing crushed stone and residual shear strength. Reduced shear area, increased normal stress, uneven stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

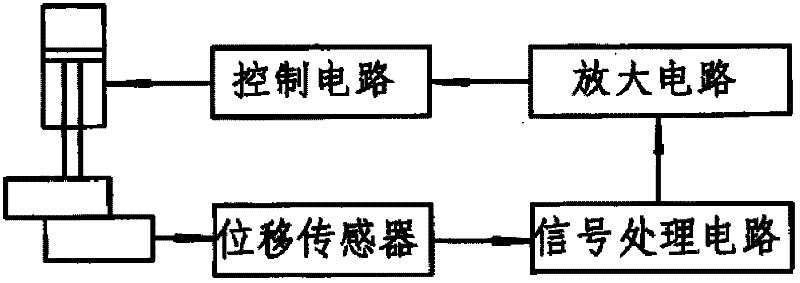

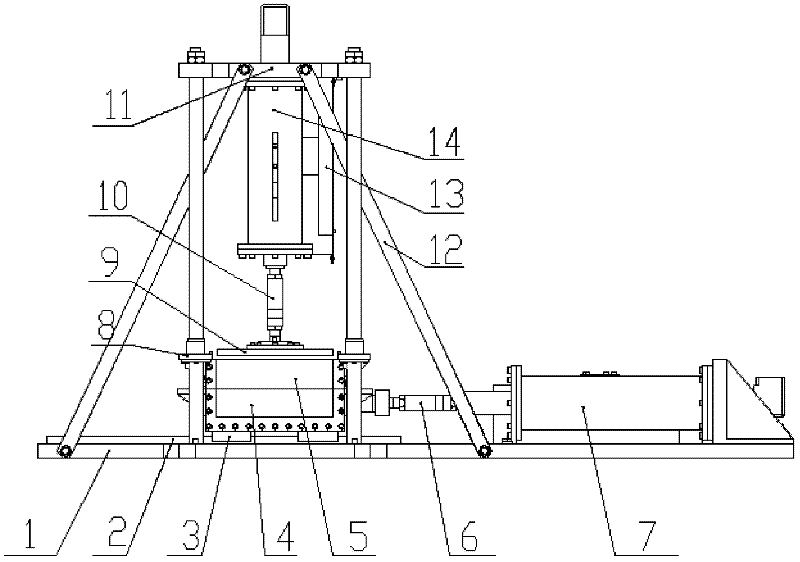

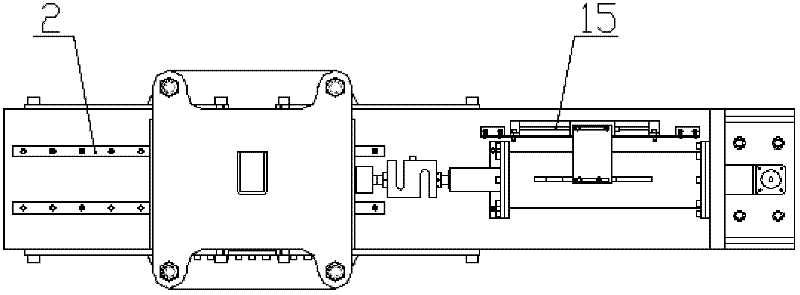

[0014] Such as figure 1 , figure 2 , image 3 As shown, the medium-sized direct shear instrument of the present invention includes base plate 1, double track 2, lower shear box 4, loading plate 9, horizontal loading device 7 and vertical loading device 14, vertical loading device supports 11, and the upper direct shear box is fixed device 8. The displacement of the lower shearing box is measured by the grating ruler 15 installed on the horizontal loading device, and the reduction value of the shearing area is calculated, which is used to control the loading force of the vertical loading device and realize the dynamic constant of the directional stress.

[0015] The displacement signal measured by the grating ruler is processed by the signal and amplified by the amplifying circuit, and then sent to the control circuit of the vertical loading device 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com