Combined stator winding machine

A stator winding and combined technology, which is used in electromechanical devices, electric components, manufacturing of motor generators, etc., can solve the problems of large mechanism, different stator blocks, and the clamp of the winding machine is not tightly clamped, and achieves winding efficiency. High, simple structure, strong adaptability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

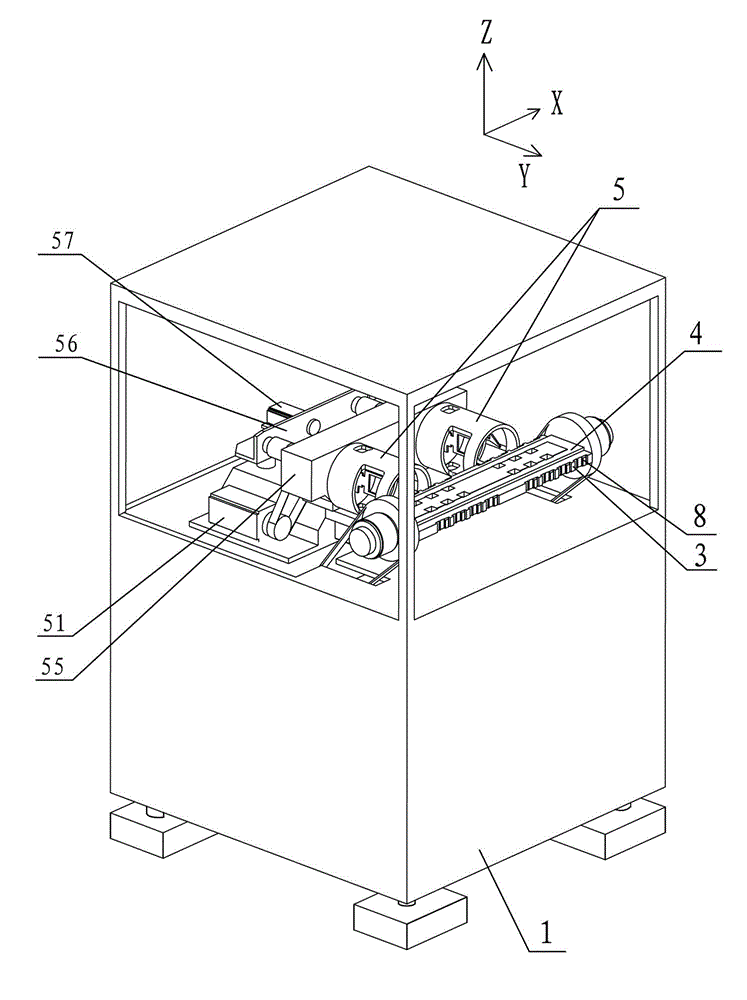

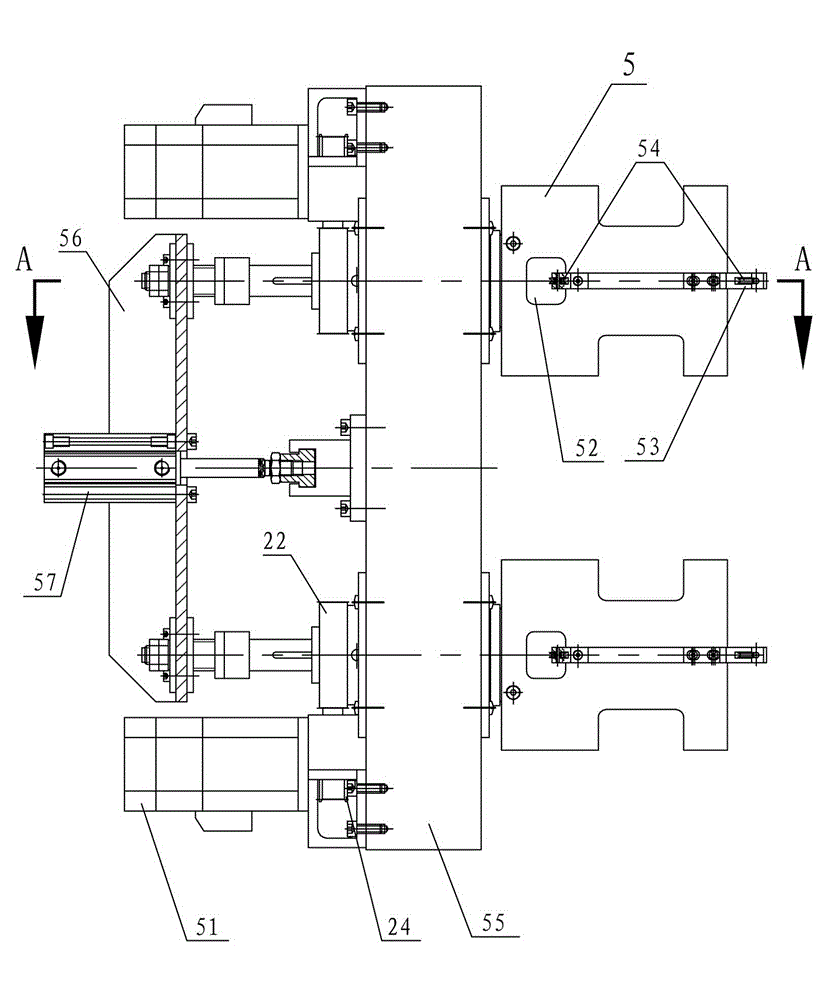

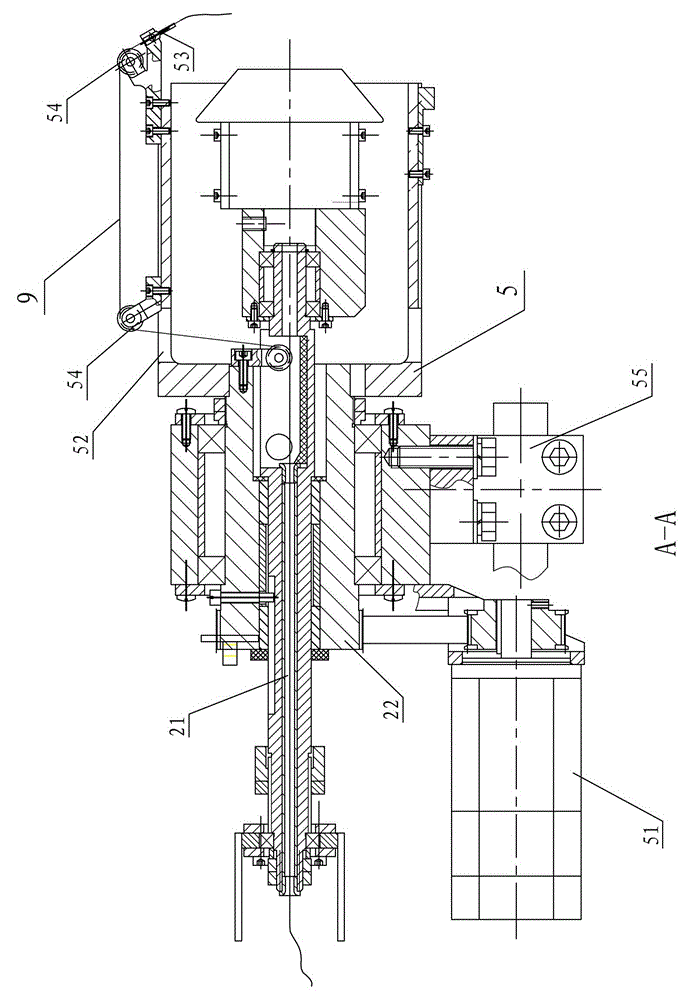

[0029] refer to Figure 1 ~ Figure 3 , combined stator winding machine, the front view is the XZ plane, the horizontal plane is the XY plane, the vertical upward direction is the positive direction of the Z axis, the horizontal direction to the right is the positive direction of the X axis, and the forward direction is the positive direction of the Y axis , the present invention includes a frame 1 and several fly forks 5 arranged in the frame 1, and each fly fork 5 is connected with a plurality of independent fly fork motors 51, and is driven to rotate by the fly fork motors 51.

[0030] Further as a preferred embodiment, the negative part of the Y-axis of the fly fork 5 is connected with the driven synchronous wheel 22 provided with an inlet channel 21 in the middle, and the driven synchronous wheel 22 is connected with the fly fork motor 51 through a synchronous belt .

[0031] Further as a preferred embodiment, the fly fork 5 is a cylindrical member, a wire outlet 52 is op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com