Ignition system, gas generating device for airbag, and gas generating device for seatbelt pretensioner

An ignition system and igniter technology, applied in the field of ignition systems, can solve problems such as difficult protection, insufficient protection capacity of diodes or rheostats, etc., and achieve the effects of improving reliability, simplifying structure, and eliminating malfunctions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

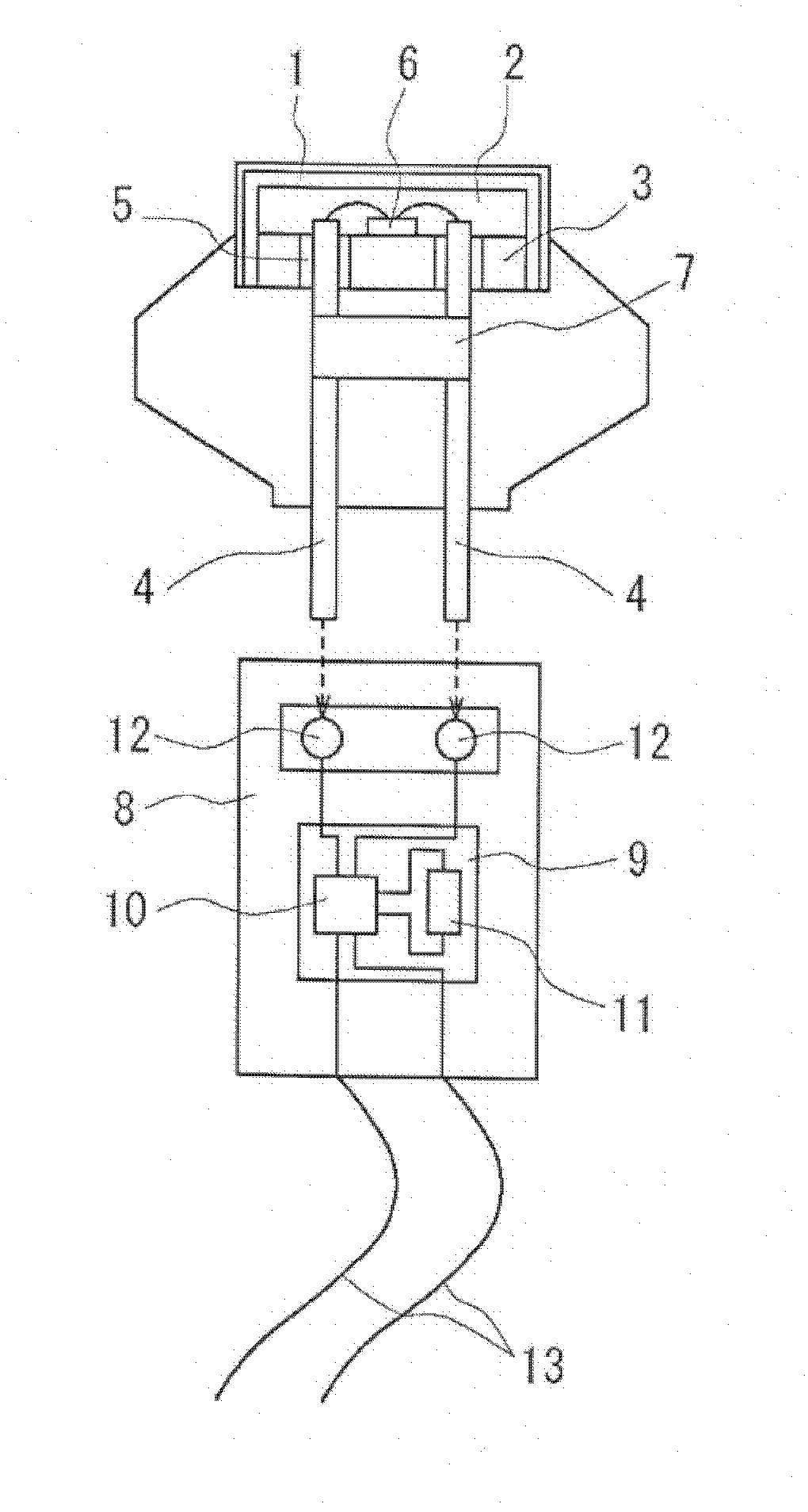

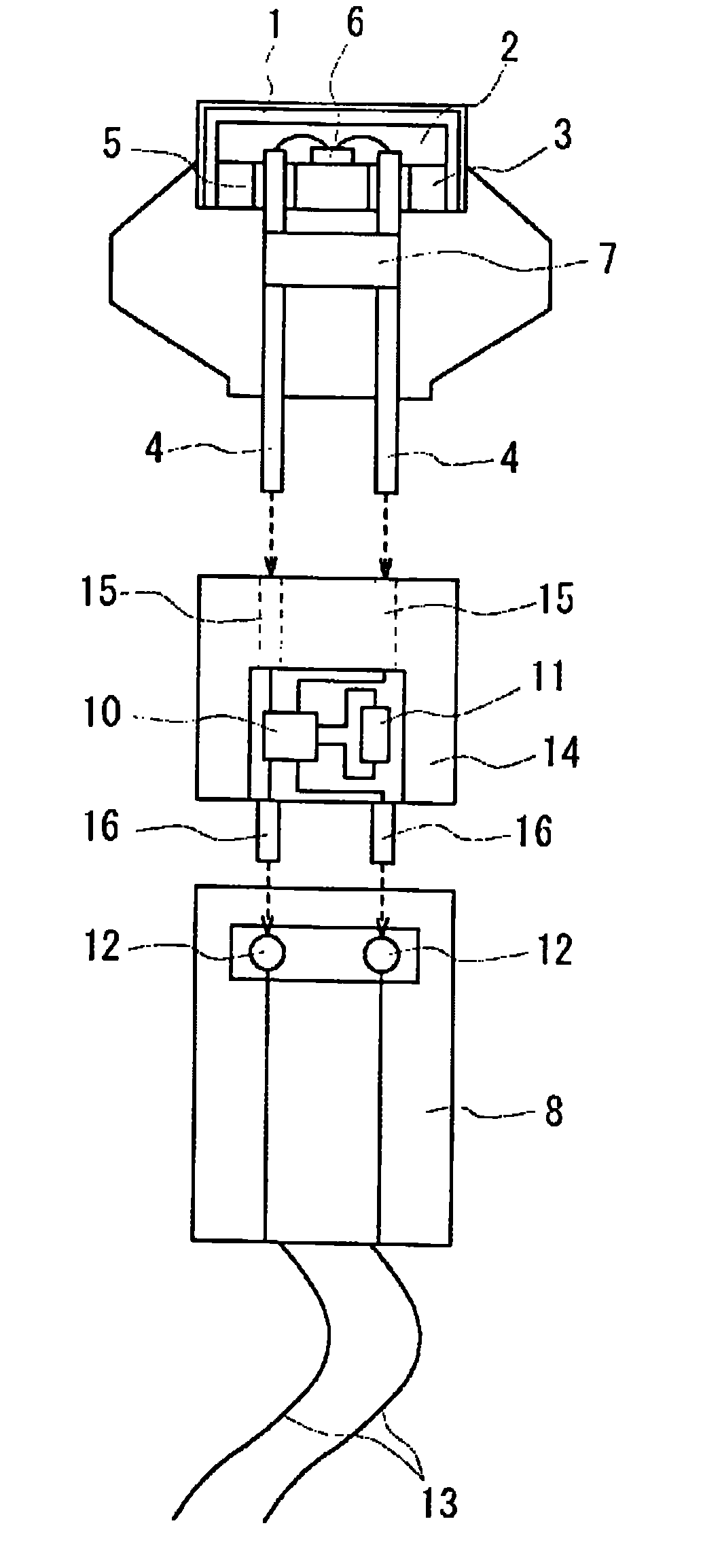

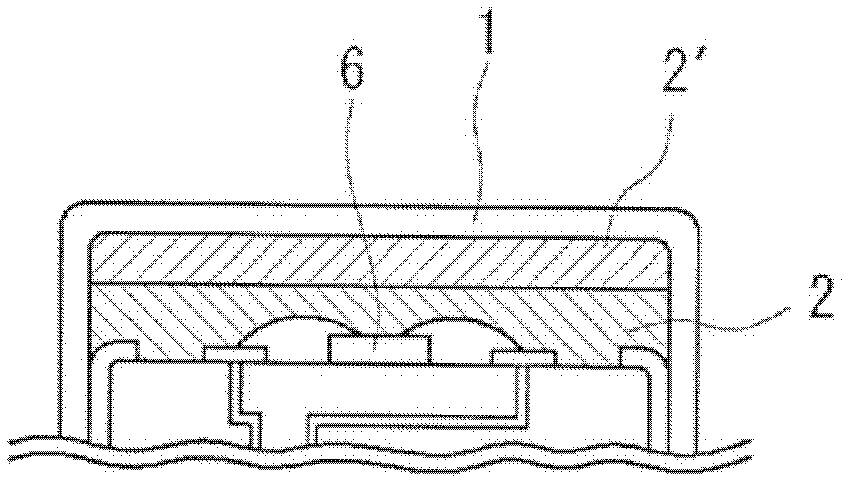

Image

Examples

example

[0151] The igniter of the present invention is separated from the electrical circuit for communication and ignition, and a capacitor for electrostatic protection is mounted on the igniter side to prevent malfunction caused by static electricity or interference, and to use a fixed electrostatic capacity The discharge of the ignition capacitor is used to reliably calculate the parameters during operation.

[0152] The obtained results are shown in Tables 1 to 4.

[0153] [Table 1]

[0154] Table 1. Resistance change during static electricity resistance test due to capacitor capacity (N=5) Electrostatic application conditions (i)

[0155]

[0156] [Table 2]

[0157] Table 2. Resistance change during static electricity resistance test due to capacitor capacity (N=5) Static application conditions (ii)

[0158]

[0159] Table 1 and Table 2 show the amount of resistance change of the ignition element of the igniter due to static electricity resistance. Table 1 is the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com