Split type 360° fish pond automatic feeding machine

A split-type, feeding machine technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems of small activity range, complex structure, and inability to feed in a large area, reducing workload and energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

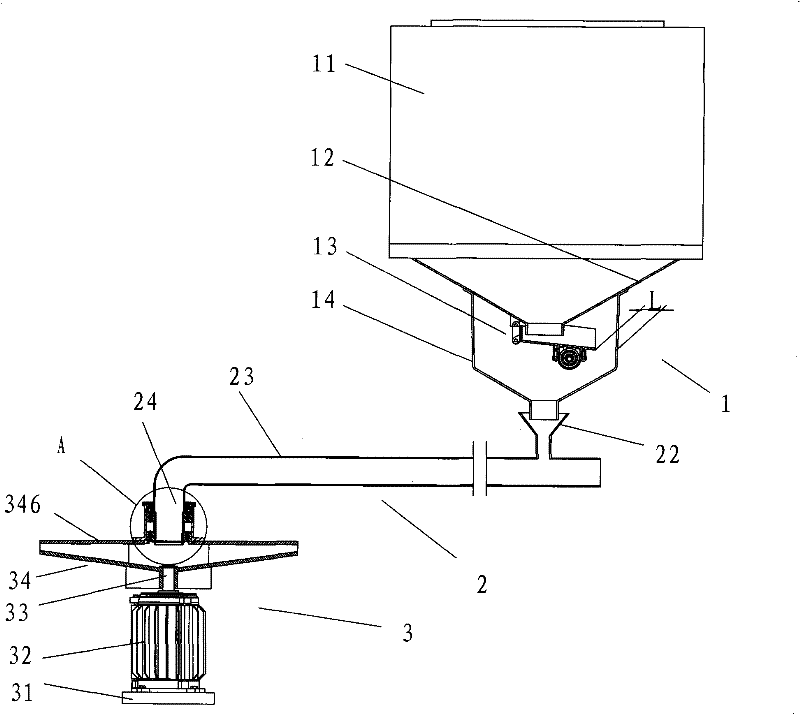

[0039] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-20 :

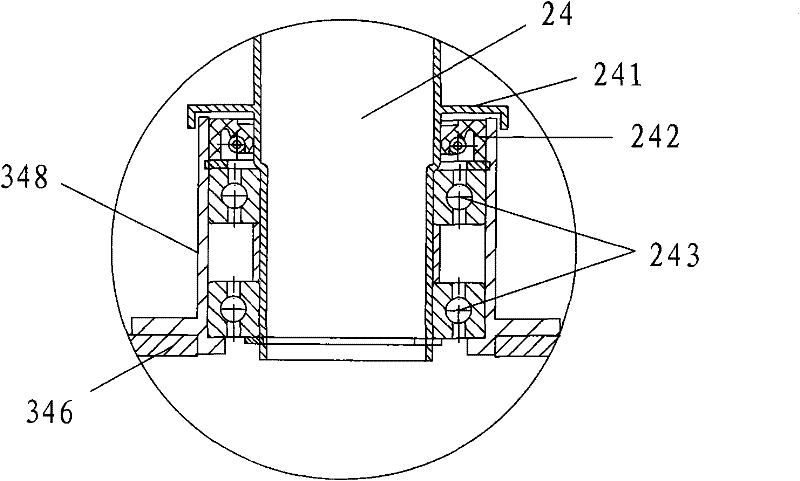

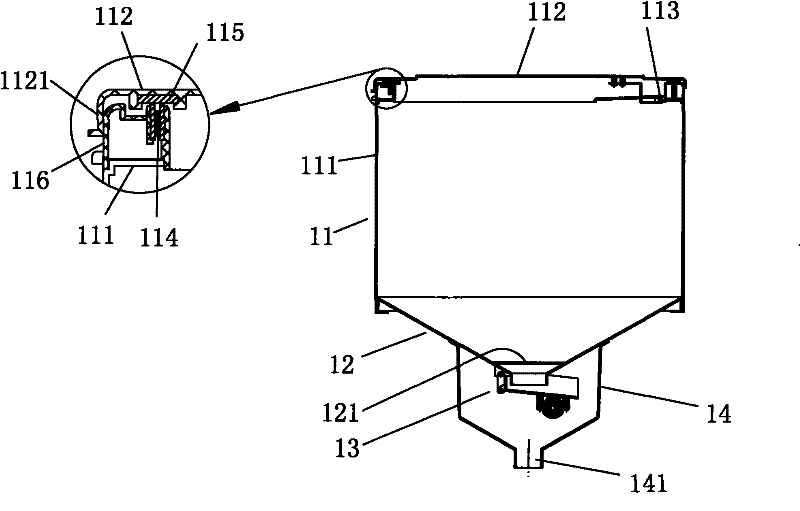

[0040] Split-type 360° automatic feeding machine for fishing ponds, a feeding mechanism 2 is provided between the feeding mechanism 1 and the throwing mechanism 3, and the feeding mechanism 1 is: a conical hopper 12 with a large upper part and a smaller one at the lower part The upper opening is upwardly connected with a material box 11, and the lower part is connected with a feeder 13; the throwing mechanism 3 is: the upper part of the 360° horizontal throwing tray 34 is centered with a feed inlet 3461, and the lower base 341 of the throwing tray 34 is There is a material throwing disc rotating shaft 33 downwards, and the material throwing disc rotating shaft 33 is driven by a power device or directly driven by a material throwing motor 32; the conveying mechanism 2 is: one end of a transversely arranged material conveying pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com