360-degree feed throwing disc and fishpond feeding machine with feed throwing disc

A technology of throwing trays and feeding machines, which is applied in fish farming, applications, climate change adaptation, etc., can solve the problems of complex structure, small range of activities, manual feeding, etc., and achieve the effect of low energy consumption and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

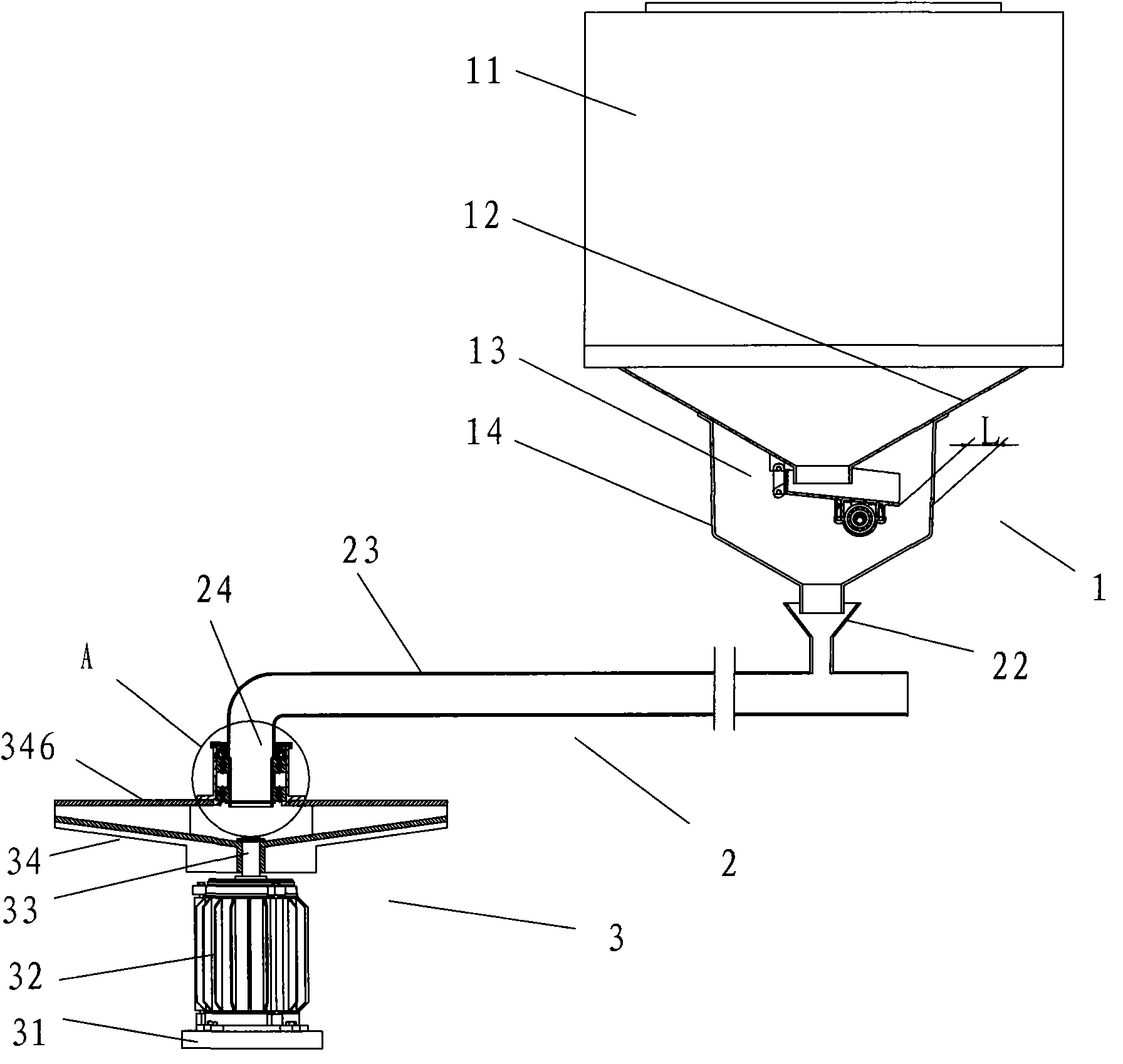

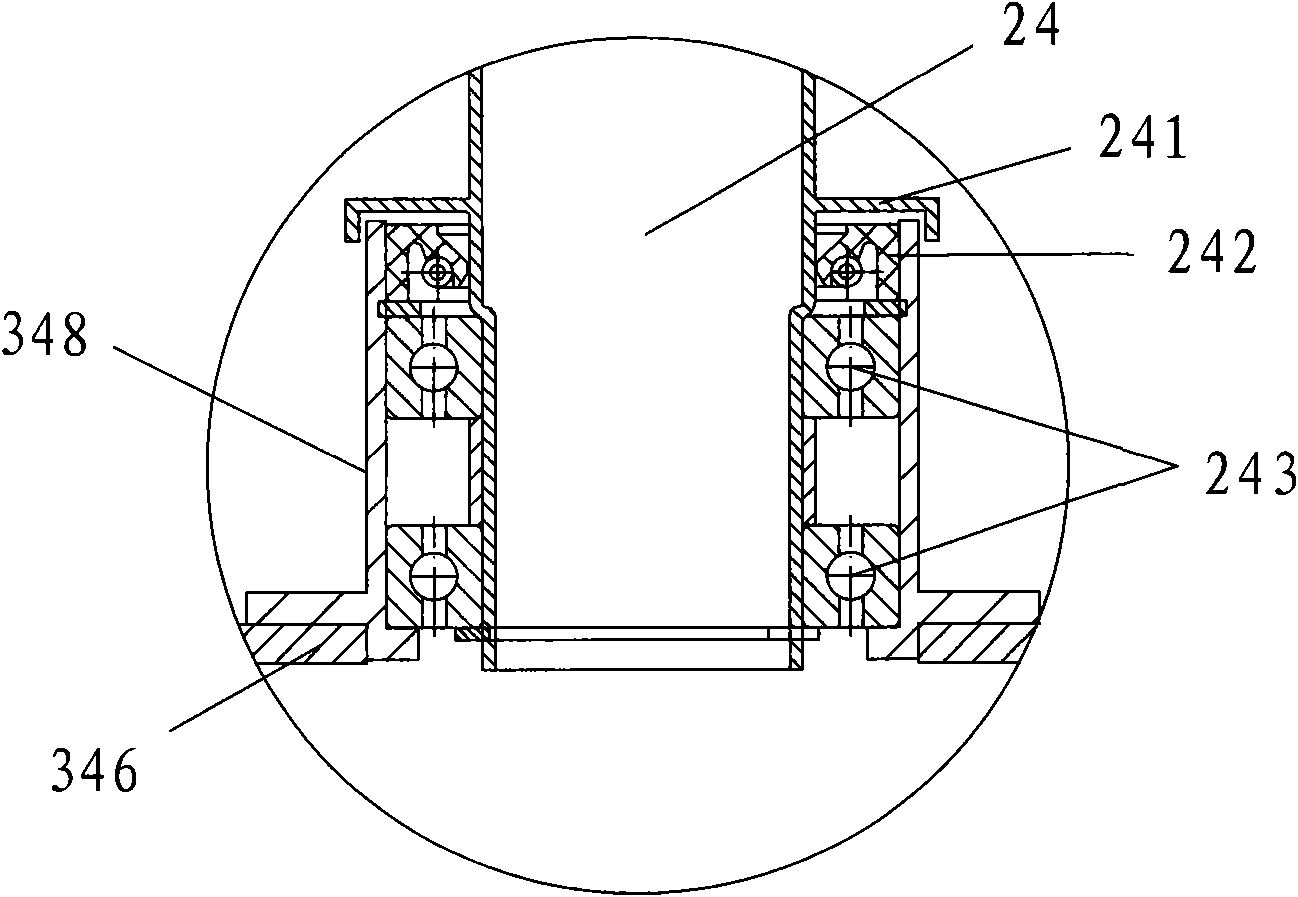

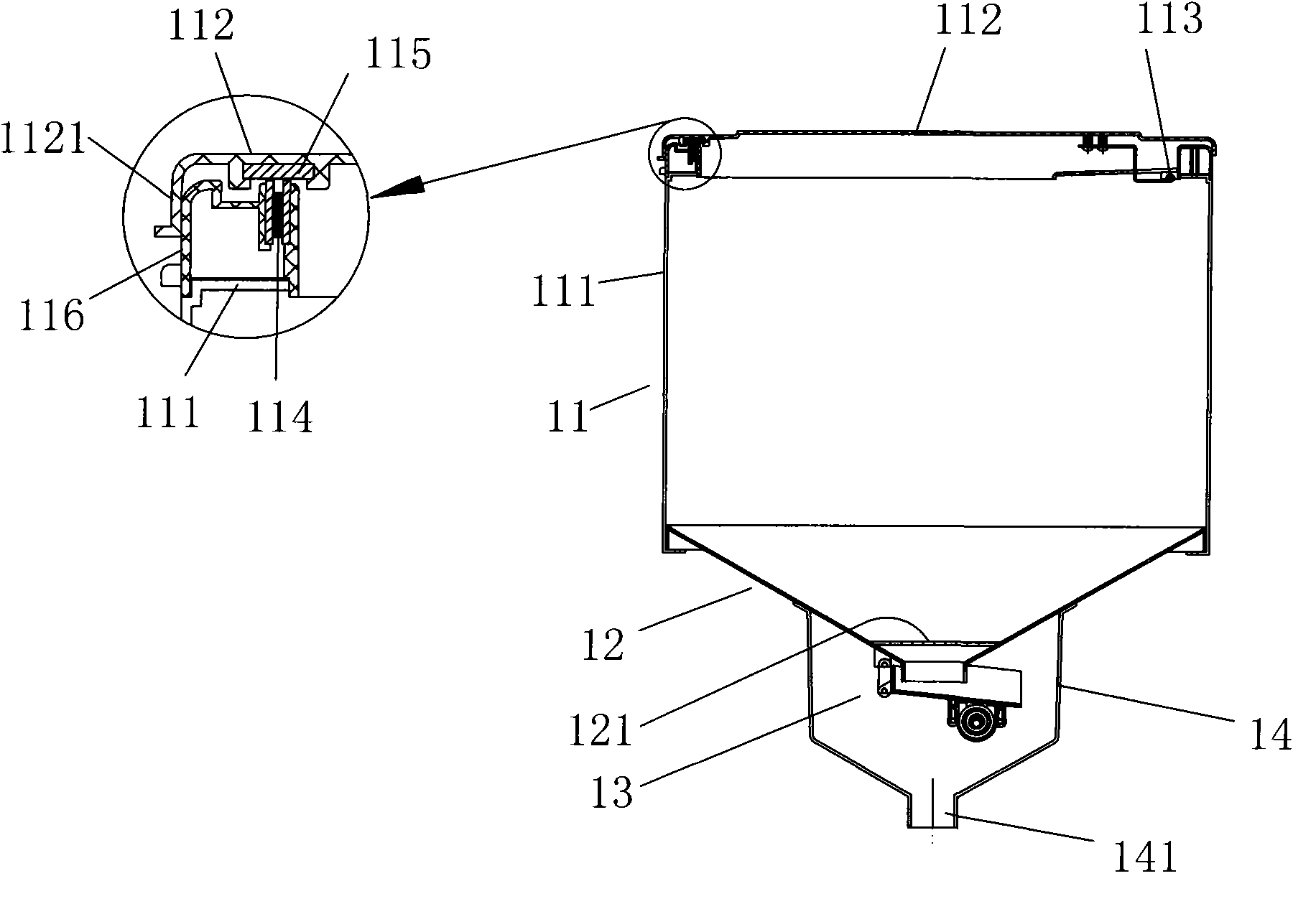

[0044] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-25 :

[0045] 360 ° throwing tray 34 (see Figure 12-16) is: a motor shaft mounting hole 347 is provided in the middle of the base 341, a disc cover 346 with a feed port 3461 in the middle is provided on the base 341, and a certain radius between the base 341 and the disc cover 346 is radial outward Evenly distributed with throwing guide plate 342, the outer end of guide plate 342 is long and has short interval setting (referring to Figure 13 ), so that the thrown feed is far and near, and a throwing channel 345 is formed between two adjacent guide plates 342. The lower surface of the base 341 is radially provided with a reinforcing rib 343 that generates cooling airflow downwards. The base 341 can be plastic or Made of aluminum die-casting, the throwing guide plate 342 is formed by metal stamping, the upper part of the throwing guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com