Electric motor with hollow ventilating main shaft and feeder with the same

A technology of electric motors and feeding machines, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of inability to feed large areas, excessively dense damage, and limited range of activities, and achieve reduced broken rates, large coverage areas, and The effect of preventing feed waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

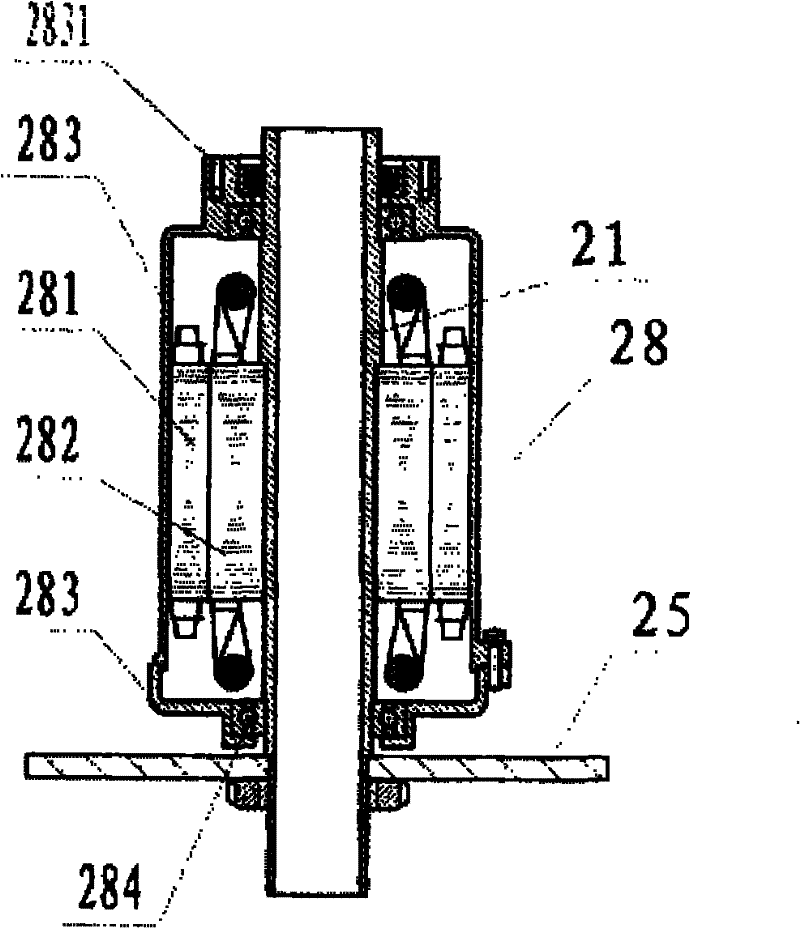

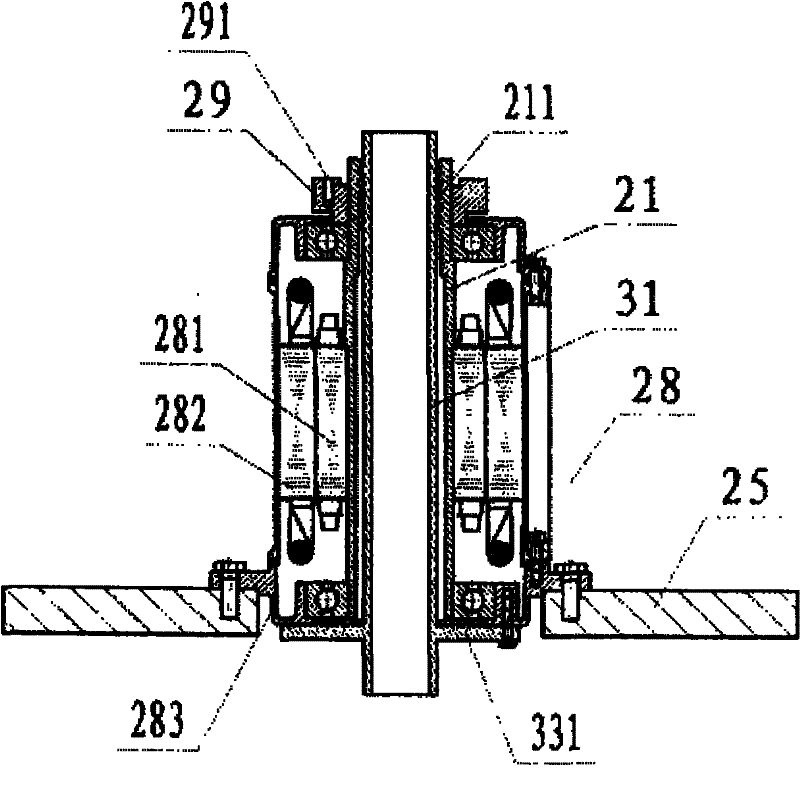

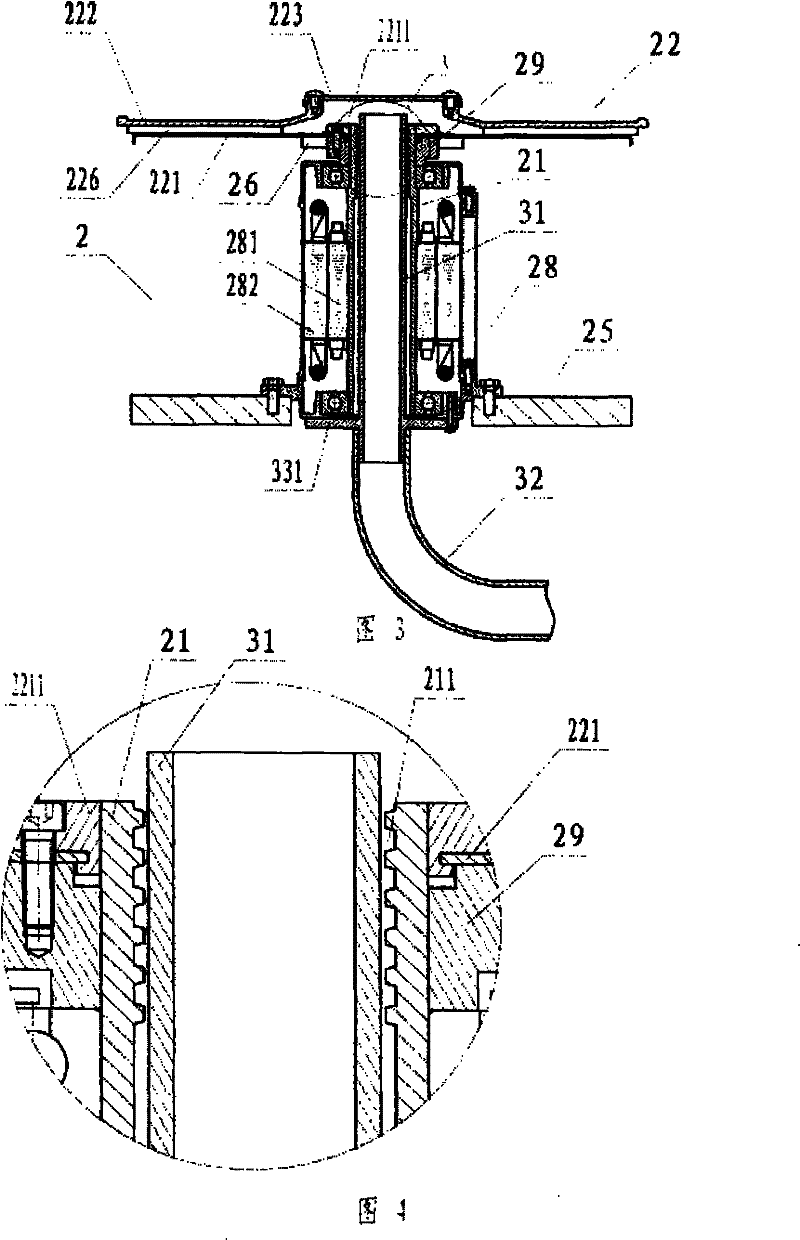

[0017] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-25 : the motor with hollow ventilated main shaft of the present invention mainly is made up of stator 282, rotor 281, main shaft 21, bearing 284 etc., and electric motor comprises AC and DC motor, and described main shaft 21 is the structure of hollow, and the lower end of casing 283 is connected There is a flange, a bearing 284 is arranged between the housing 283 and the main shaft 21, the stator 282 is fixed on the housing 283, the housing 283 is connected to the base 25 through the flange, and the rotor 281 is fixed on the main shaft 21 to form an inner rotor motor ; or the stator 282 is fixed on the main shaft 21, the rotor 281 is fixed on the housing, and the main shaft 21 is fixed on the frame 25 to form an outer rotor motor.

[0018]One end of the main shaft 21 of the above-mentioned inner rotor motor is fixed with a flange 29 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com