Split 360-degree automatic dried diet feeder for fishpond

A split-type, feeding machine technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems of small activity range, complex structure, artificial feeding, etc., and achieve the effect of reducing workload and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

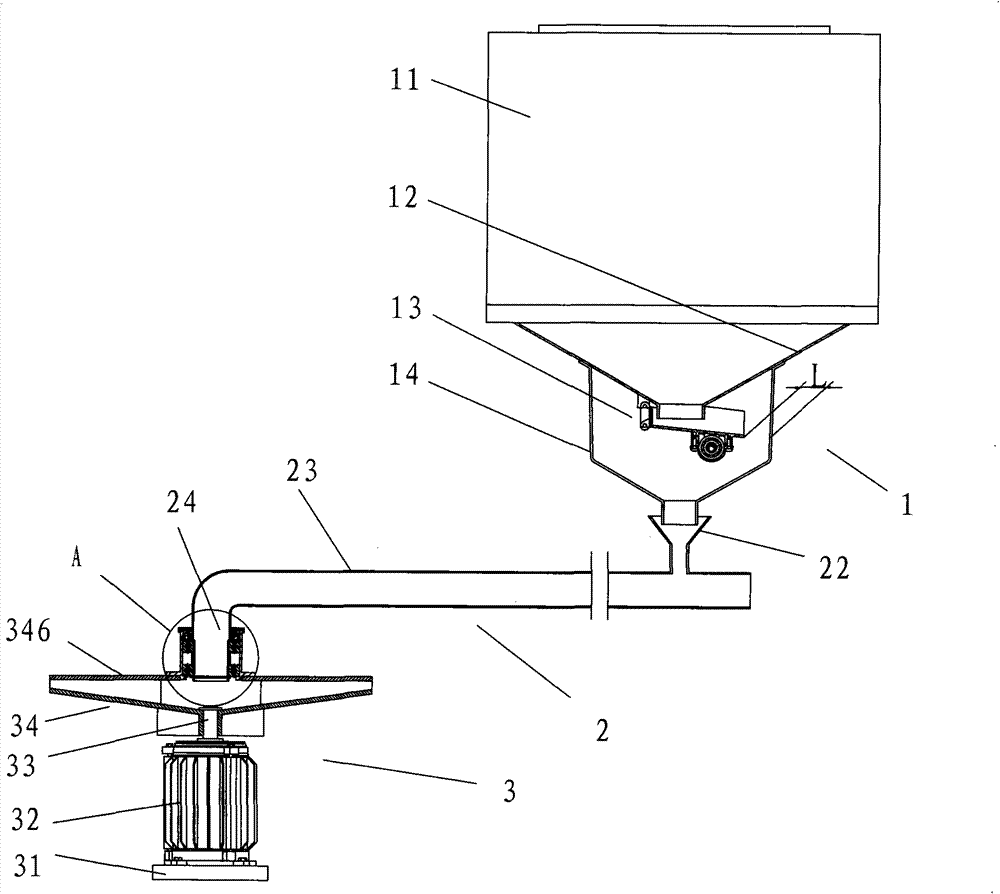

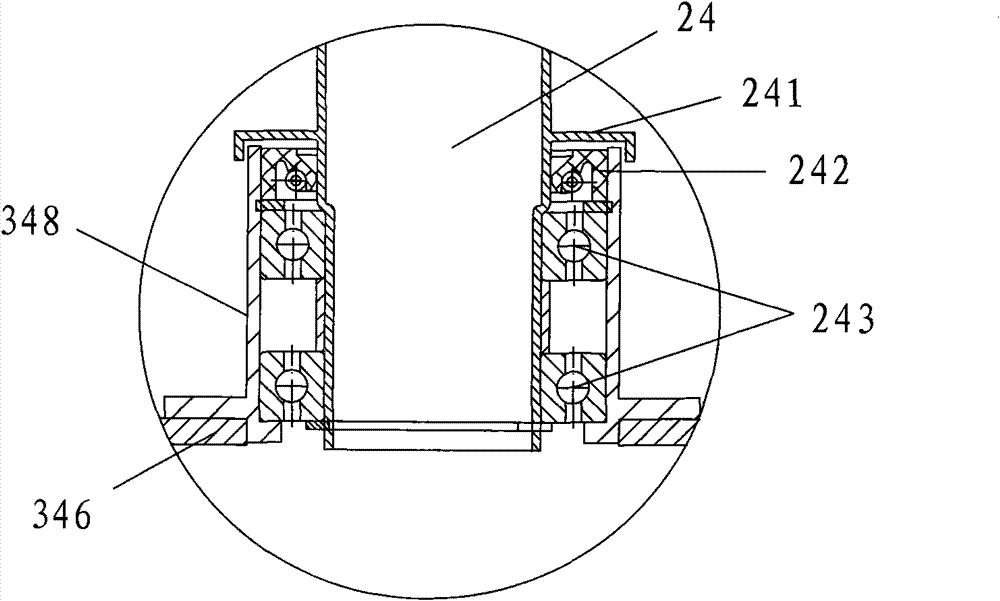

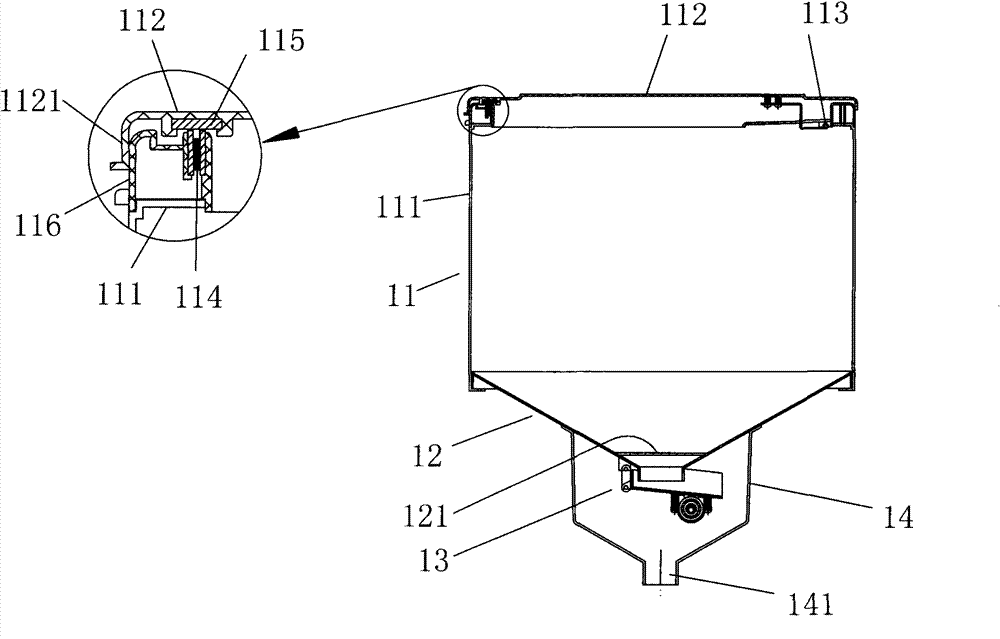

[0039] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-20 :

[0040] Split-type 360° automatic feeding machine for fishing ponds, a feeding mechanism 2 is provided between the feeding mechanism 1 and the throwing mechanism 3, and the feeding mechanism 1 is: a conical hopper 12 with a large upper part and a smaller one at the lower part The upper opening is upwardly connected with a material box 11, and the lower part is connected with a feeder 13; the throwing mechanism 3 is: the upper part of the 360° horizontal throwing tray 34 is centered with a feed inlet 3461, and the lower base 341 of the throwing tray 34 is There is a material throwing disc rotating shaft 33 downwards, and the material throwing disc rotating shaft 33 is driven by a power device or directly driven by a material throwing motor 32; the described feeding mechanism 2 is: one end of a horizontally arranged feeding pipe 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com