Cleaning machine movable scraper

A cleaning machine and scraper technology, used in snow surface cleaning, cleaning methods, cleaning methods and utensils, etc., can solve problems such as inability to remove accumulations, affecting COD emission reduction, and missing scraping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

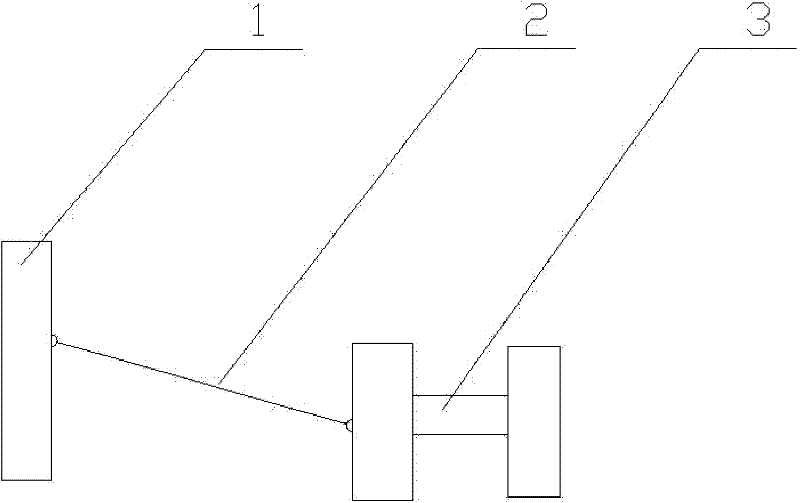

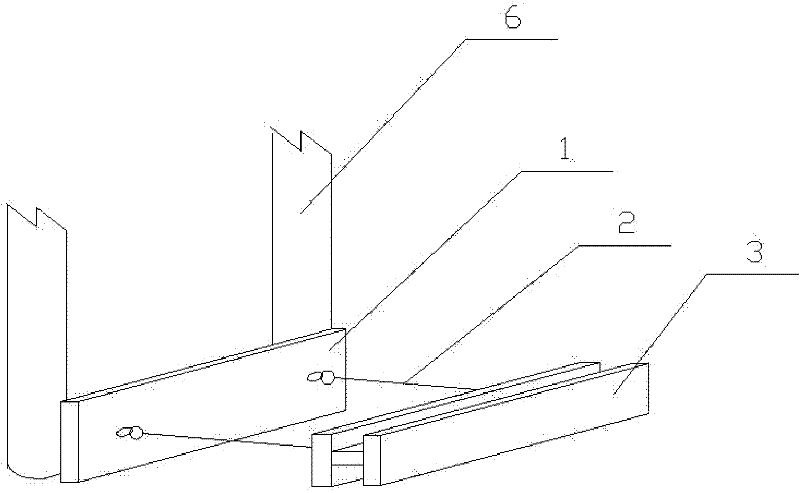

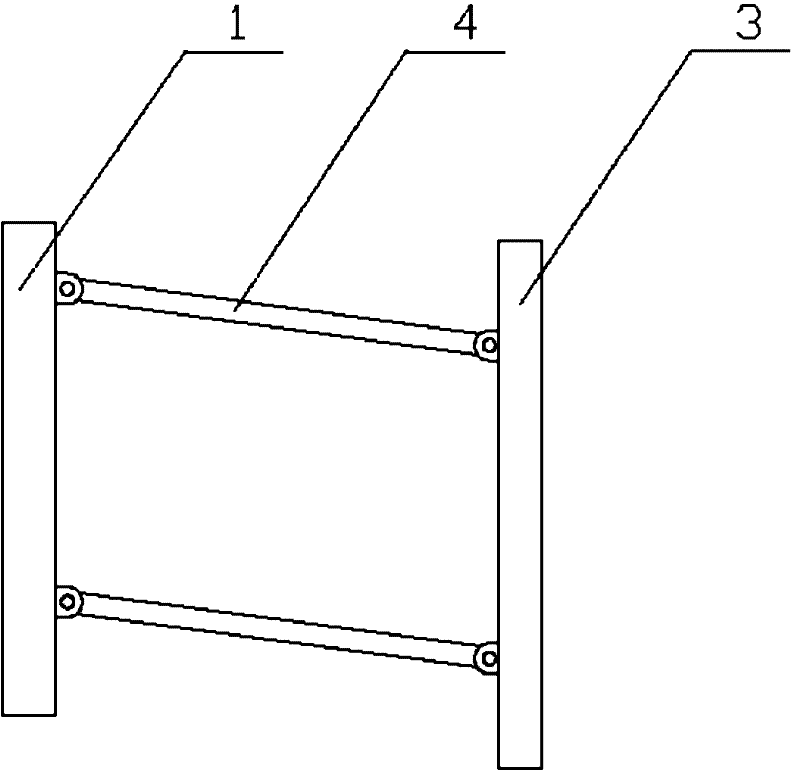

[0013] The movable scraper of the cleaning machine has a connecting plate 1 and a scraper 3, a parallel connecting rod 4 or a rope 2 is arranged between the connecting plate and the scraper, the two ends of the parallel connecting rod 4 or the two ends of the rope 2 are connected with the connecting plate 1 and the The scrapers 3 are flexibly connected respectively. The connecting plate 1 can also be fixedly connected with the frame 5, and the scraper 3 dynamically connected is housed in the frame 5. During use, the connecting plate 1 is fixedly connected with the frame 6 of the cleaning machine, and the connecting plate 1 can also be a part of the cleaning machine frame. The bottom surface of the scraper is attached to the cleaned bottom surface. 1. The parallel connecting rod 4 or the rope 2 or the frame 5 pulls the scraper 3 to move forward. The scraper drags the accumulation and moves up and down along the bottom surface to be cleaned, always sticking to the bottom surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com