Lateral stamping device for shock absorber support of automobile engine

A technology for automobile engines and stamping devices, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of inability to guarantee product size, low production efficiency, low product qualification rate, etc., to speed up mold maintenance efficiency and production efficiency. High, high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

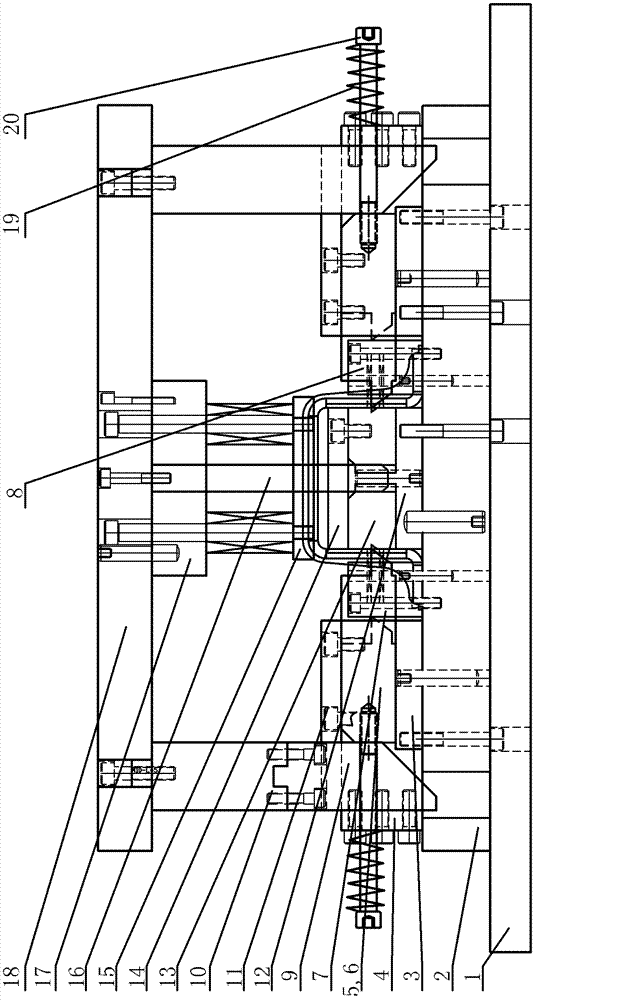

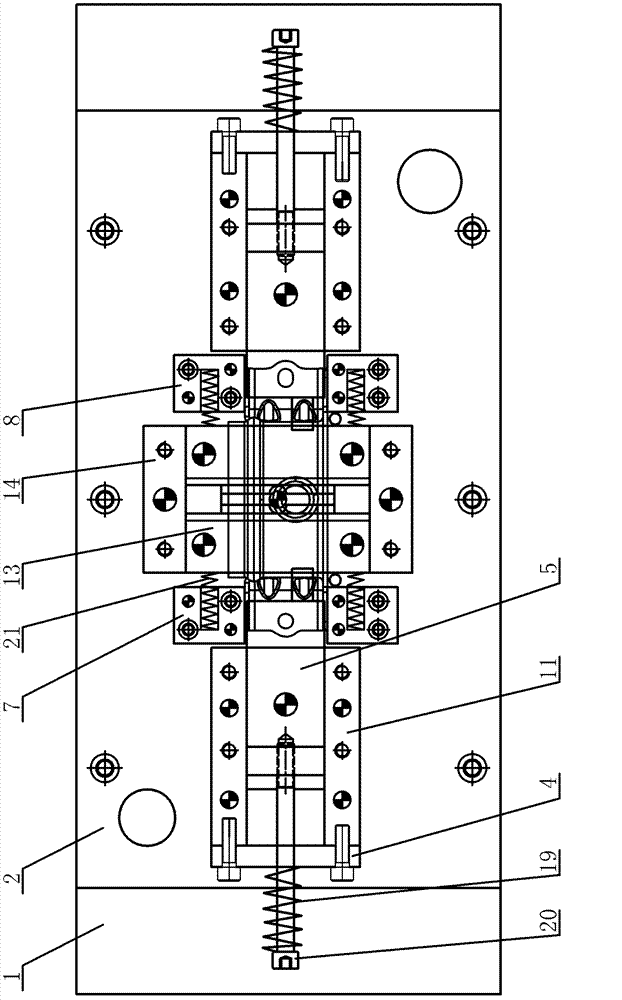

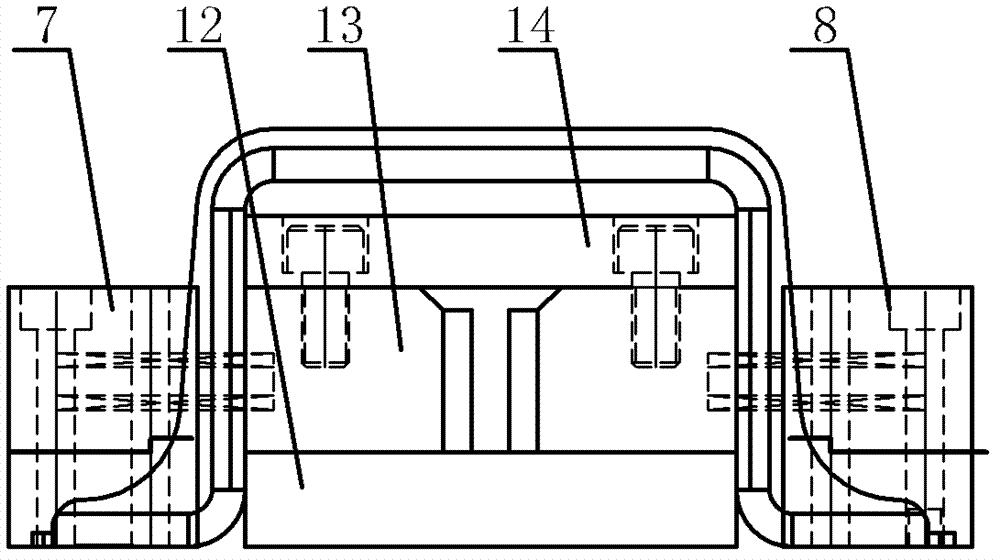

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] Figure 1~Figure 6 Among them, including bottom plate 1, lower template 2, first guide block 3, baffle plate 4, slider 5, punch 6, first positioning block 7, second positioning block 8, inclined iron 9, inclined iron seat 10 , cover plate 11, second guide block 12, inner slider 13, inner slider cover plate 14, pressure plate 15, insertion knife 16, upper fixing plate 17, upper template 18, first spring 19, screw 20, the first Two springs 21 etc.

[0019] like figure 1 , figure 2 As shown, the present invention is a lateral stamping device of an automobile engine shock absorber bracket, comprising an upper die and a lower die.

[0020] The patrix comprises an upper template 18, and an upper fixed plate 17 and two inclined irons 9 are fixed under the upper template 18. Two inclined irons 9 are respectively fixed on the lower surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com