Spinneret plate and method for producing cross-shaped hollow high-imitation cotton fine-denier polyester yarns

A technology of fine-denier polyester and spinneret, which is applied in filament/thread forming, textile and papermaking, fiber treatment, etc. It can solve the problems of not having cotton-like characteristics and effects, thermal insulation performance needs to be improved, etc., and achieve hole shape design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

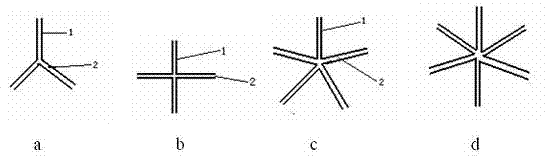

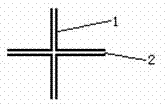

[0017] The 96F spinneret is used, and there are 4 equilateral angular spinneret slots and 1 diagonally arranged spinneret holes, and the inner angle of the angular spinneret slots is 90°. The width of the four spinneret slots is 0.09mm, the length of the single side of the spinneret slots is 0.1mm, and the side distance 2 of the two spinneret slots is 0.09mm, see figure 1 b. The spinning speed is 2700m / min, the spinning temperature is 285°C, and the cross hollow POY of 265dtex / 96f is obtained, the elongation at break is 130%, and then the false twisting process is carried out on the false twisting texturing machine, the speed is 600m / min, the false twisting The speed ratio is 1.3, the temperature of the first heating box for false twisting deformation is 180°C, and the temperature of the second heating box for false twisting and setting is 160°C. Obtain 167dtex / 96F cross hollow high imitation cotton fine denier polyester false twisted textured yarn DTY with a hollowness of 1...

Embodiment 2

[0019] 288F 4L type spinneret is used, and the spinneret hole setting is the same as the above example. The width of the four spinneret slots 1 is 0.05mm, the length of one side of the spinneret slot is 0.5mm, and the distance between two adjacent spinneret slots is 0.03mm. The spinning speed is 2500m / min, the spinning temperature is 270°C, and the cross hollow POY of 180dtex / 288f is obtained, the elongation at break is 145%, and then the false twisting process is carried out on the false twisting texturing machine, the speed is 500m / min, the false twisting The speed ratio is 1.45, the temperature of the first heating box for false twisting and texturing is 165°C, and the temperature of the second heating box for false twisting and setting is 150°C. Get 111dtex / 288f cross hollow high imitation cotton fine denier polyester false twist textured yarn DTY.

Embodiment 3

[0021] A 144F 4L spinneret is used, the width of the spinneret slot 1 is 0.07mm, the length of one side of the spinneret slot is 0.8mm, and the distance 2 between two adjacent spinneret slots is 0.07mm. The spinning speed is 2600m / min, the spinning temperature is 278°C, and the cross hollow POY of 270dtex / 144f is obtained, the elongation at break is 138%, and then the false twisting process is carried out on the false twisting texturing machine, the speed is 550m / min, the false twisting The speed ratio is 1.38, the temperature of the first heating box for false twisting deformation is 175°C, and the temperature of the second heating box for false twisting and setting is 150°C. Get 167dtex / 144f cross hollow high imitation cotton fine denier polyester false twist textured yarn DTY.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com