Jean fabric and manufacturing method thereof

A denim and weaving technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of lack of soft and comfortable feeling, user discomfort, and high denim texture, so as to achieve soft hand feeling and better elasticity , knitted elegant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

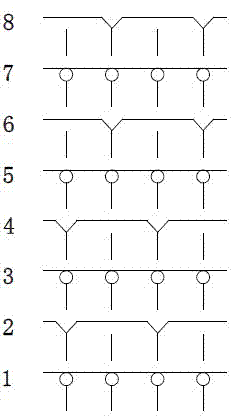

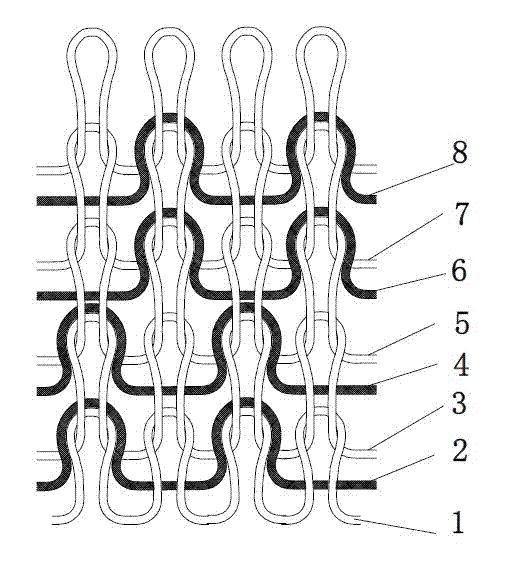

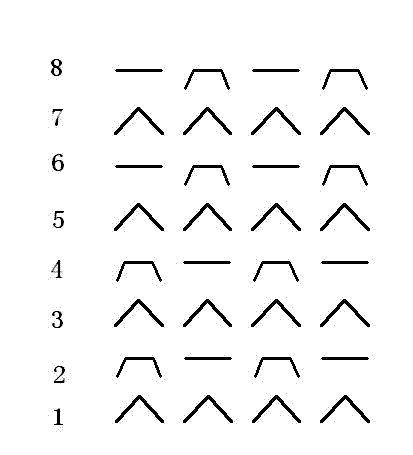

[0023] see Figure 1-Figure 3 , the denim fabric of this embodiment, its minimum weave cycle is 8 courses and 4 wales, wherein the 1st, 3rd, 5th and 7th roads are full-knit weave structures made of blue yarn and spandex, the 2nd, Routes 4, 6, and 8 are alternate structures of tuck weaves and floating weaves made of woolen white yarn. The 2nd and 4th lines on the 1st wale of the minimum tissue cycle are tuck tissue units, the 6th and 8th lines are floating thread tissue units; the 2nd and 4th lines on the 2nd coil wale of the minimum tissue cycle are floating lines Organization unit, the 6th and 8th lines are tuck organization units; the 2nd and 4th lines on the 3rd wale of the minimum tissue cycle are tuck organiza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com