Method for Installing Prestressed Steel Cylindrical Concrete Pipe in Narrow Space in Casing

A prestressed steel and concrete pipe technology, applied in the direction of pipes/pipe joints/fittings, pipe laying and maintenance, machinery and equipment, etc., can solve problems such as limited site space, and achieve the effect of short construction period, flexible use and less investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

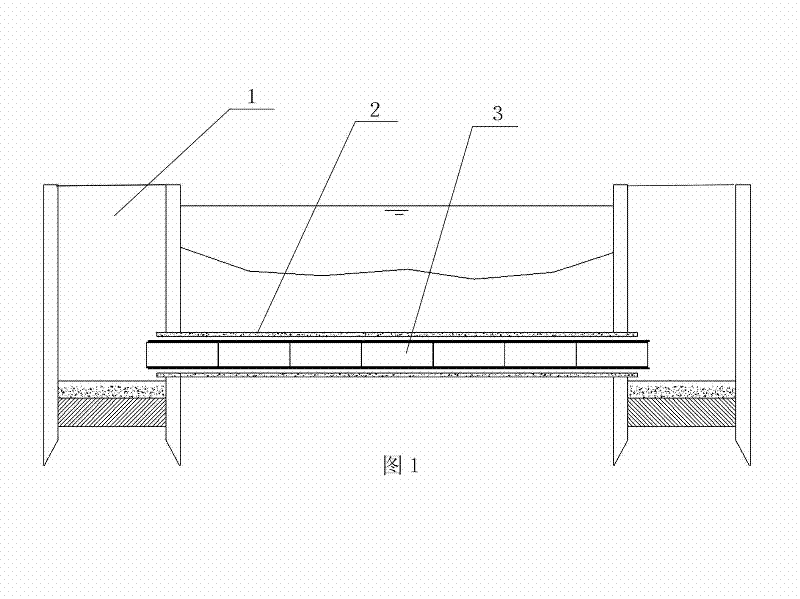

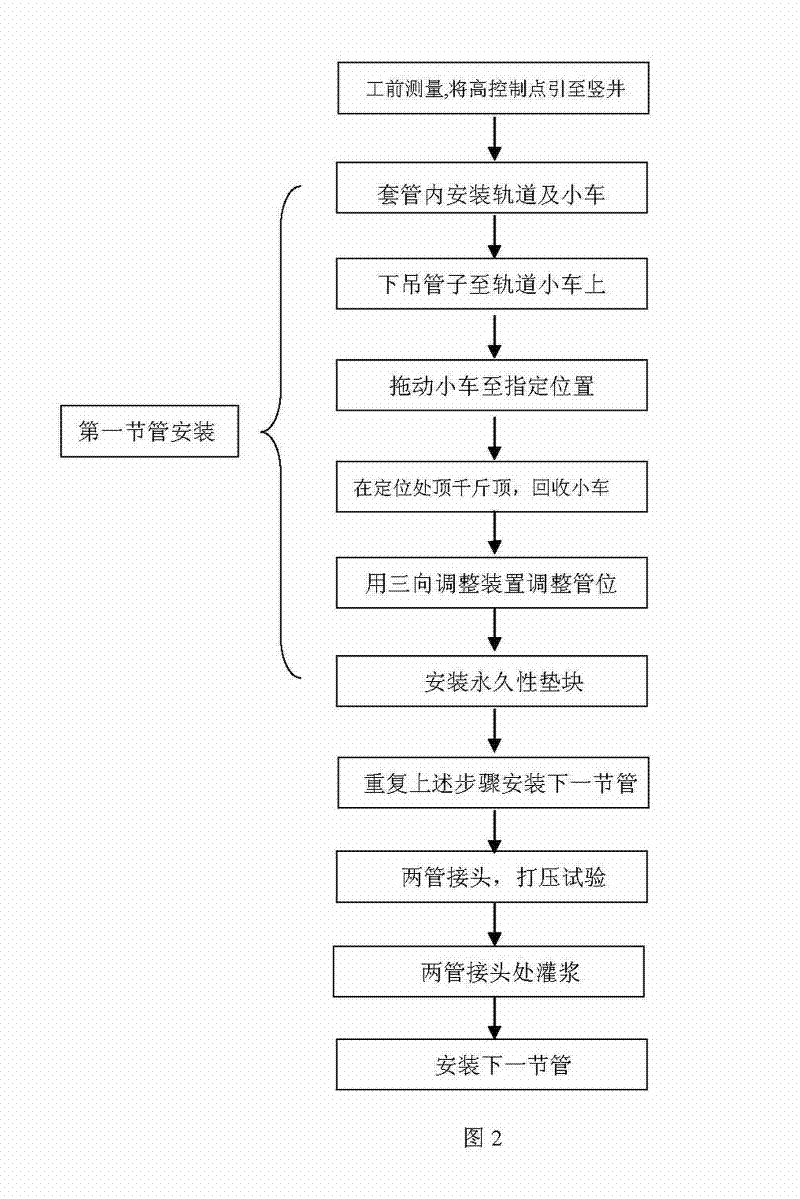

[0027] Such as figure 1 , figure 2 Shown, the method for installing the prestressed steel cylinder concrete pipe in the narrow space in the casing of the present invention. Including pre-project fixed-point measurement before installing the prestressed steel cylinder concrete pipe 3, releasing the axis of the pipe jacking, and leading the high-level control point into the operation shaft 1; setting a seal at the joint before the two-section prestressed steel cylinder concrete pipe 3 is docked Parts, at the junction of two prestressed steel cylinder concrete pipes 3 joints with seals installed, pressurize the inside of the pipe to perform a sealing test, and perform grouting and sealing on the outside of the pipe. The process steps also include:

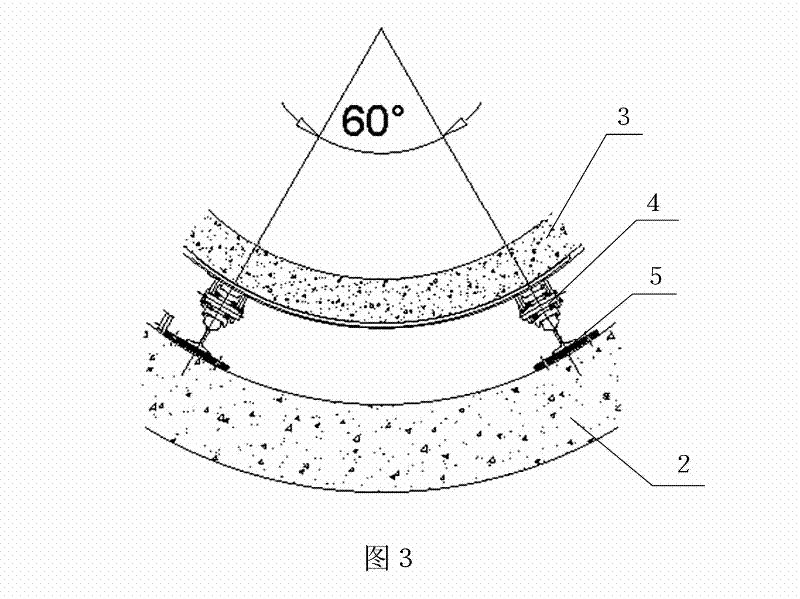

[0028] Step 1. Fix the steel sleeper pad on the inner wall of the casing 2. Two parallel and straight rails 5 with the same top elevation are fixed on the steel sleeper pad. The two rails 5 form an angle of 60° and are perpendicular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com