Oil filter device for range hood

A technology for range hoods and oil nets, which is applied in the direction of removing oil fumes, applications, and household stoves. It can solve problems such as large air intake resistance, increased noise, and clogged dense filter screens, so as to improve the filtering effect, improve the suction efficiency, and The effect of high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

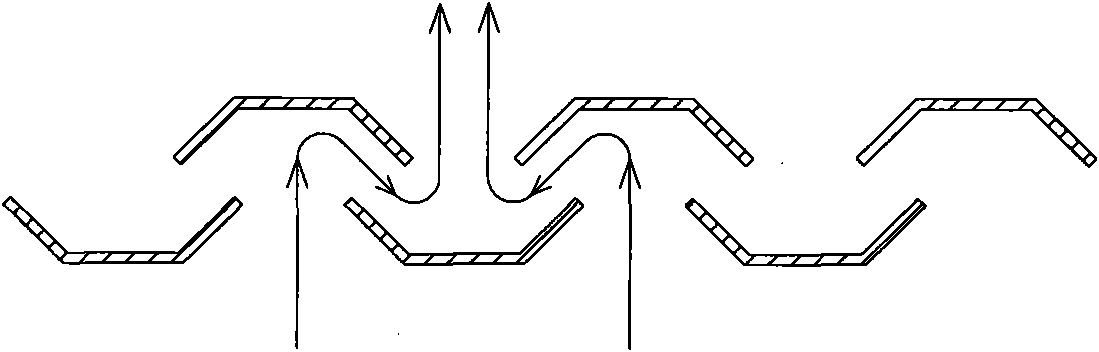

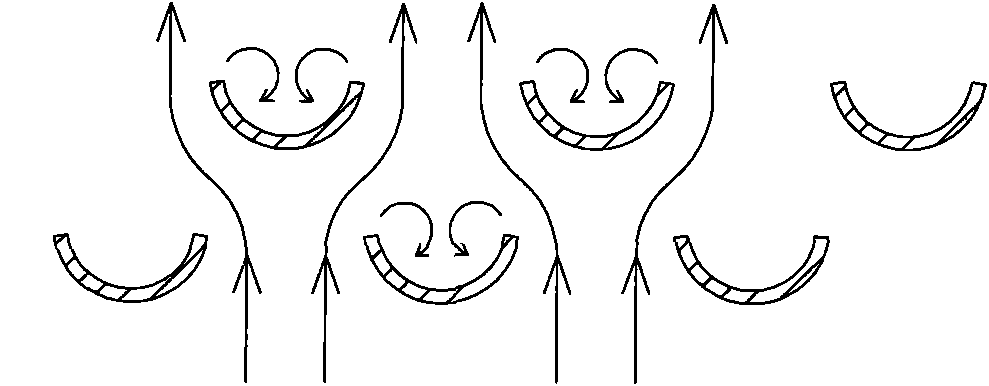

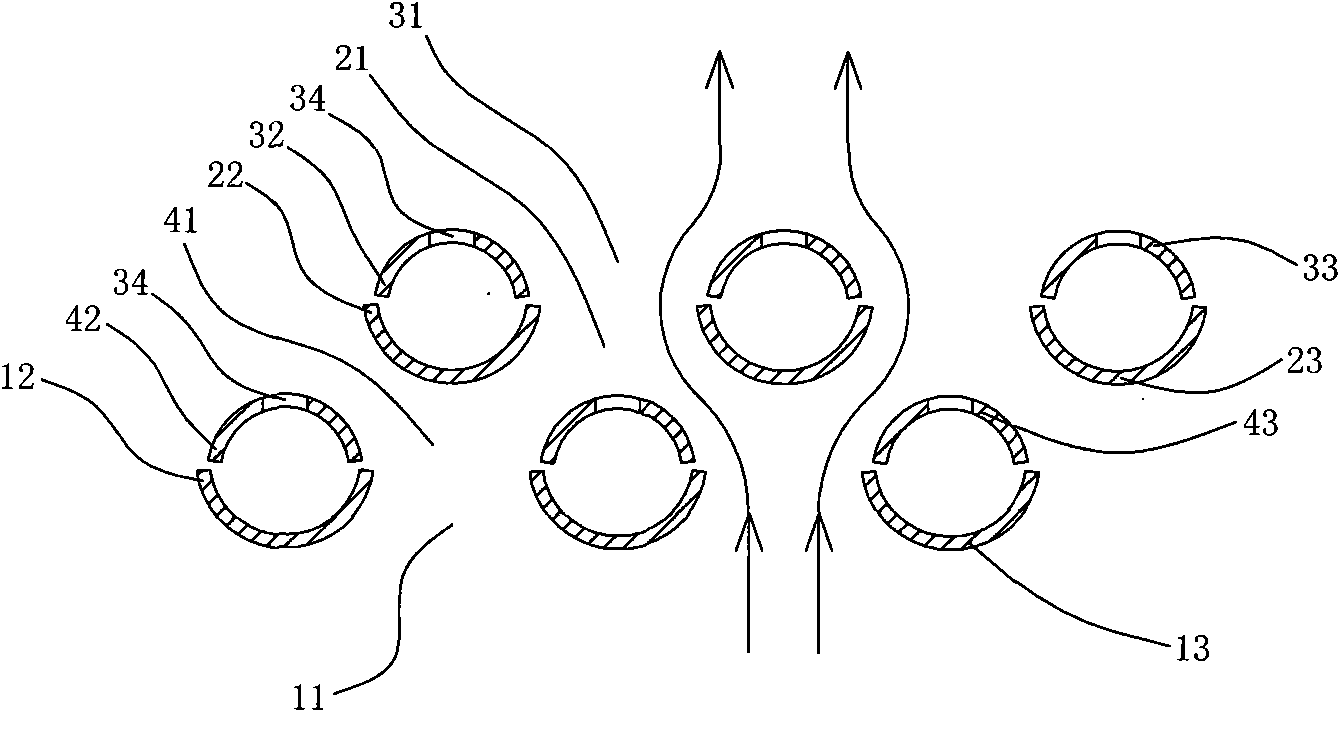

[0029] Embodiment: An oil screen device for a range hood, comprising at least three layers of oil screens, based on the direction of use (the side away from the inside of the range hood is the outside), and the first oil screen from the outside to the inside of the range hood 1 and the second oil net 2 are also provided with a third oil net 3, and the first oil net 1, the second oil net 2 and the third oil net 3 are respectively provided with elongated first, second and third oil nets along the inclined surface of the oil net. 2. Three ventilation holes 11, 21, 31, the first ventilation hole 11 is provided with a closed ring-shaped first flange 12 towards the inside of the range hood, and the second ventilation hole 21 is provided with a " n"-shaped second flange 22, the second flange 22 faces the inside of the range hood, and the side of the third ventilation hole 31 along its length direction and the upper end edge at a relatively higher position are provided with facing towa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com