A method for constructing a mesomechanical model of graded crushed stone and calibrating micromechanical parameters

A technology of micromechanical parameters and graded crushed stone, which is used in the application of stable shear force to test the strength of materials, scientific instruments, measuring devices, etc. Difficulties in the study of crushed stone, structural characteristics and mechanical properties of difficult graded crushed stone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

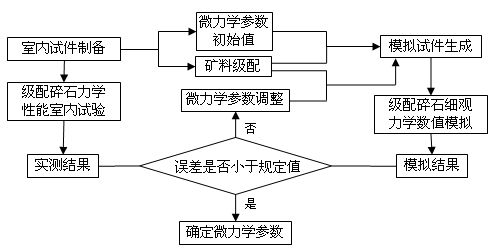

[0072] Such as figure 1 As shown, this embodiment provides a method for constructing a mesomechanical model of graded crushed stone and calibrating micromechanical parameters. Taking the numerical simulation of the CBR test as an example, the following steps are carried out:

[0073] 1) Construction of mesomechanical model

[0074] (1) Test of basic parameters:

[0075] The crushed stone density test results are shown in Table 1, and the mineral material gradation and maximum dry density are shown in Table 2.

[0076] Table 1 Crushed stone density

[0077] Aggregate particle size (mm)

19~31.5

9.5~19

4.75~9.5

≤4.75

Apparent density (g / cm 3 )

2.712

2.709

2.692

2.681

[0078] Table 2 Mineral material grading

[0079]

[0080] (2) Simulation of mold trial

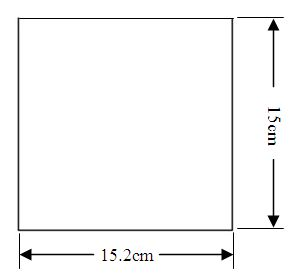

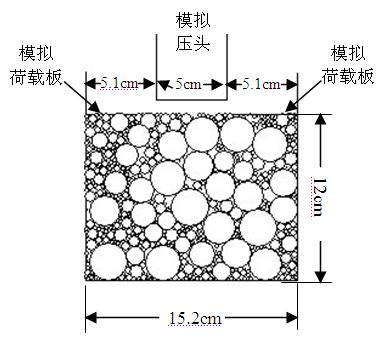

[0081] The size of the test mold used in the CBR indoor test is Φ15.2cm×h15cm. Using PFC 2D The command "wall" generates two vertical...

Embodiment 2

[0121] see figure 1 , a method for constructing a mesomechanical model of graded crushed stone and calibrating micromechanical parameters in this embodiment, taking the numerical simulation of a triaxial test as an example, proceeds according to the following steps:

[0122] 1) Construction of mesomechanical model

[0123] (1) Test of basic parameters:

[0124] The crushed stone density test results are shown in Table 5, and the mineral material gradation and maximum dry density are shown in Table 6;

[0125] Table 5 Crushed stone density

[0126] Aggregate particle size (mm)

19~31.5

9.5~19

4.75~9.5

≤4.75

Apparent density (g / cm 3 )

2.712

2.709

2.692

2.681

[0127] Table 6 Mineral Material Grading

[0128]

[0129] (2) Simulation of mold trial

[0130] The size of the test mold used in the indoor triaxial test is Φ30cm×h75cm. Using PFC 2D The built-in command "wall" generates a closed ...

Embodiment 3

[0163] see figure 1 , a method for constructing a mesomechanical model of graded gravel and calibrating micromechanical parameters in this embodiment, taking the numerical simulation of a direct shear test as an example, proceeds in the following steps:

[0164] 1) Construction of mesomechanical model

[0165] (1) Test of basic parameters

[0166] The crushed stone density test results are shown in Table 9, and the mineral material gradation and maximum dry density are shown in Table 10;

[0167] Table 9 Crushed stone density

[0168] Aggregate particle size (mm)

19~31.5

9.5~19

4.75~9.5

≤4.75

Apparent density (g / cm 3 )

2.712

2.709

2.692

2.681

[0169] Table 10 Mineral Material Grading

[0170]

[0171] (2) Simulation of mold trial

[0172] Simulation of the Upper Shear Box: Using PFC 2D The built-in command "wall" generates two vertical walls with a length of 7.5cm and one horizontal w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com