Method and apparatus for checking and controlling the removal of hydrogen fluoride from process gases

A process gas, hydrogen fluoride technology, applied in chemical instruments and methods, perfluorocarbon/hydrofluorocarbon capture, separation methods, etc., can solve the problem of not exceeding the emission limit, difficult to determine the hydrogen fluoride emission, etc. start effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Description of the preferred embodiment

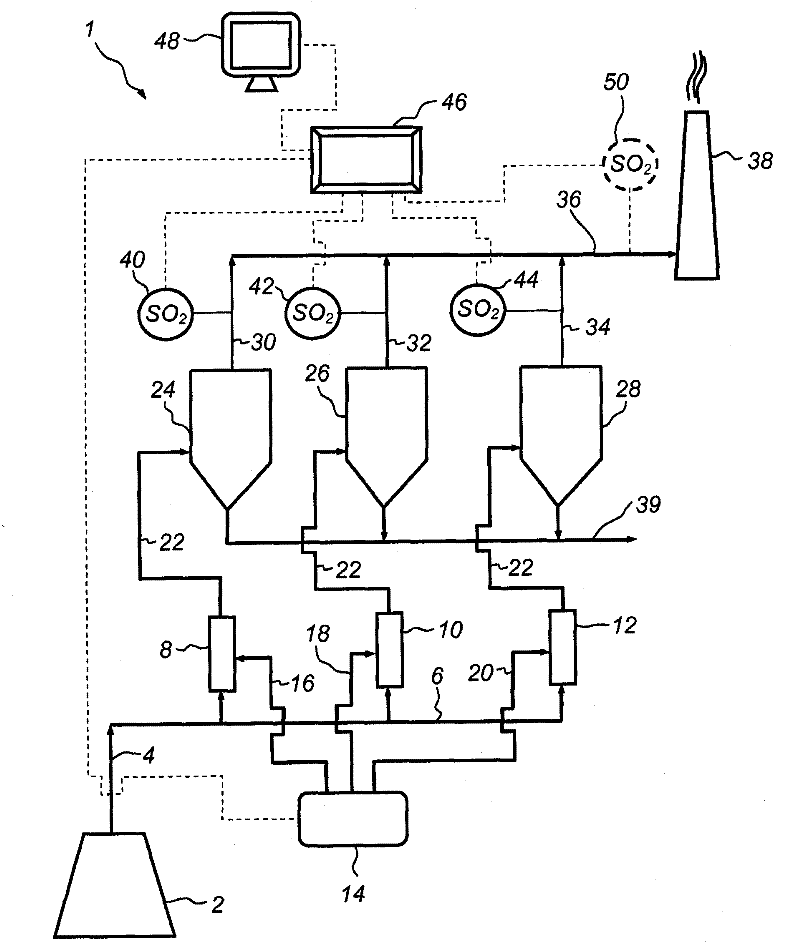

[0025] figure 1 is a schematic side view showing a gas purification system 1 constructed in accordance with a first embodiment of the present invention. The gas cleaning system 1 is designed to operate to remove gaseous pollutants and dust particles from process gases produced during an electrolytic reduction process for the production of aluminum from alumina. In this electrolytic reduction process, in order to maintain the clarity of the diagram in the figure, alumina is placed in the kettle ( figure 1 not shown in ) from which a process gas containing gaseous pollutants such as hydrogen fluoride and dust particles is produced. The resulting process gases are collected in a hood 2 . Pipe 4 is operatively connected to cover 2 to convey process gas, typically at a temperature of 60-200° C. or even higher, into horizontal distribution pipe 6 designed to operate to distribute process gas to the first A scrubber 8, a second scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com