Resin composite copper foil

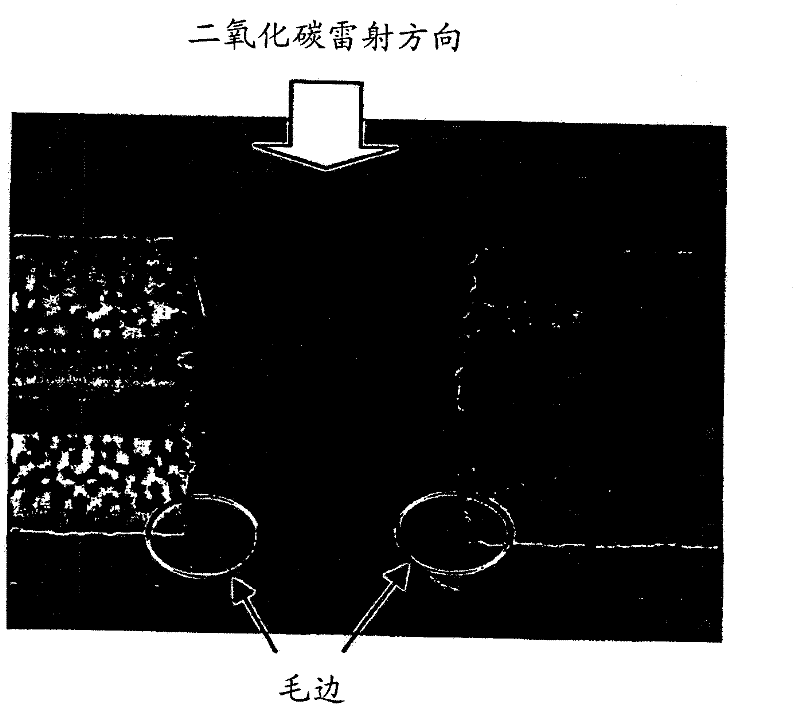

A resin composite, copper foil technology, applied in the direction of printed circuit, electrical components, printed circuit manufacturing, etc., can solve the problems of easy residue, questionable connection reliability, circuit over-etching, etc., to achieve heat resistance or moisture absorption heat resistance Good, high practicability, and excellent workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0051] Hereinafter, the present invention will be specifically described with reference to examples and comparative examples. In addition, when there is no particular description, "part" shows the weight part in solid content.

Synthetic example 1

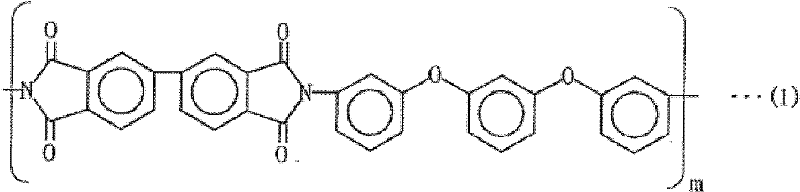

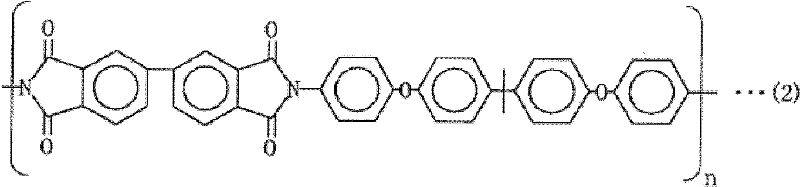

[0053] A 2L (liter) three-neck flask equipped with a stainless steel anchor type stirring rod, a trap with a nitrogen inlet tube and a stopcock, and a reflux condenser with a ball condenser In, add 117.68g (400mmol) of 3,4,3',4'-biphenyltetracarboxylic dianhydride, 87.7g (300mmol) of 1,3-bis(3-aminophenoxy)benzene, γ-valerolide 4.0g (40mmol) of ester, 4.8g (60mmol) of pyridine, 300g of N-methyl-2-pyrrolidone (hereinafter referred to as NMP) and 20g of toluene were heated at 180°C for 1 hour, cooled to around room temperature, and then added 3,4,3',4',-biphenyltetracarboxylic dianhydride 29.42g (100mmol), 2,2-bis{4-(4-aminophenoxy)phenyl}propane 82.12g (200mmol), After mixing 200 g of NMP and 40 g of toluene at room temperature for 1 hour, it heated at 180 degreeC for 3 hours, and obtained the block copolymerization polyimide resin whose solid content was 38%. The block copolymerized polyimide resin has general formula (1): general formula (2)=3:2, and the number average molec...

Synthetic example 2

[0055] Add 3, 4, 3' to a 2L three-neck flask equipped with a stainless steel anchor-type stirring rod, a trap with a nitrogen inlet pipe and a pipe latch, and a reflux condenser with a ball condenser. , 117.68g (400mmol) of 4′-biphenyltetracarboxylic dianhydride, 123.18g (300mmol) of 2,2-bis{4-(4-aminophenoxy)phenyl}propane, and 4.0g of γ-valerolactone (40mmol), pyridine 4.8g (60mmol), NMP 300g and toluene 20g, after heating at 180°C for 1 hour, cooling to around room temperature, then adding 3,4,3',4'-biphenyltetracarboxylic acid di 29.42 g (100 mmol) of anhydride, 58.47 g (200 mmol) of 1,3-bis(3-aminophenoxy)benzene, 200 g of NMP, and 40 g of toluene were mixed at room temperature for 1 hour, and then heated at 180° C. for 3 hours. A block copolymerized polyimide resin having a solid content of 38% was obtained. The block copolymerized polyimide resin has general formula (1): general formula (2)=2:3, and the number average molecular weight is 75,000, and the weight average ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com