Vacuum freeze-drying process of callicarpa leaf and preparation process of callicarpa leaf powder

A vacuum freeze-drying and preparation technology, which is applied in the direction of medical preparations containing active ingredients, plant/algae/fungus/moss ingredients, plant raw materials, etc., can solve the problem of reducing drug efficacy and active ingredients, easy loss of active ingredients, and difficult Storage and utilization, etc., to achieve the effect of saving the amount of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

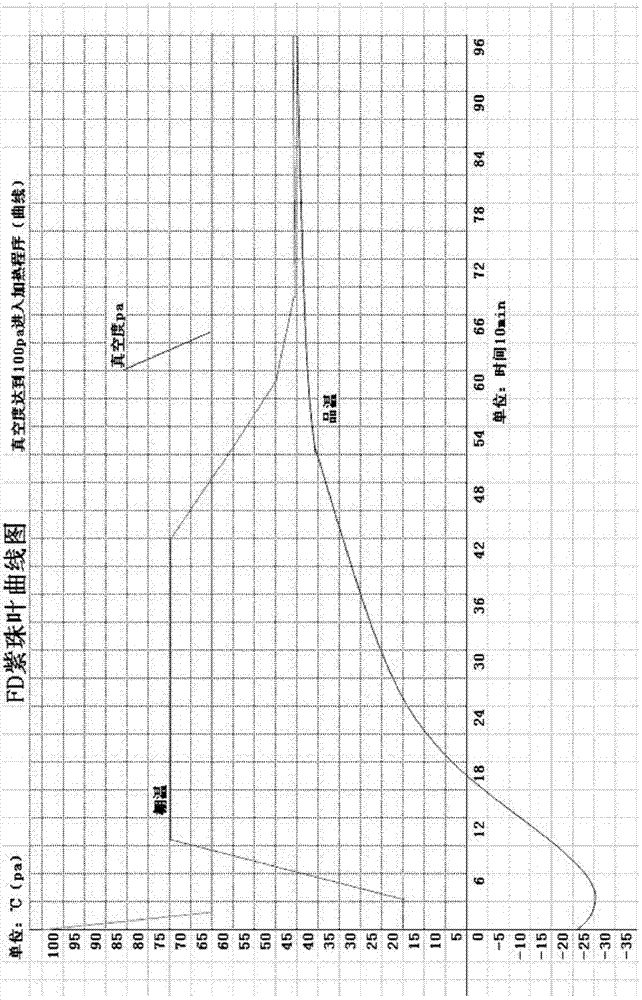

[0030] Vacuum freeze-drying of Zizhu leaves was carried out by vacuum freeze-drying machine.

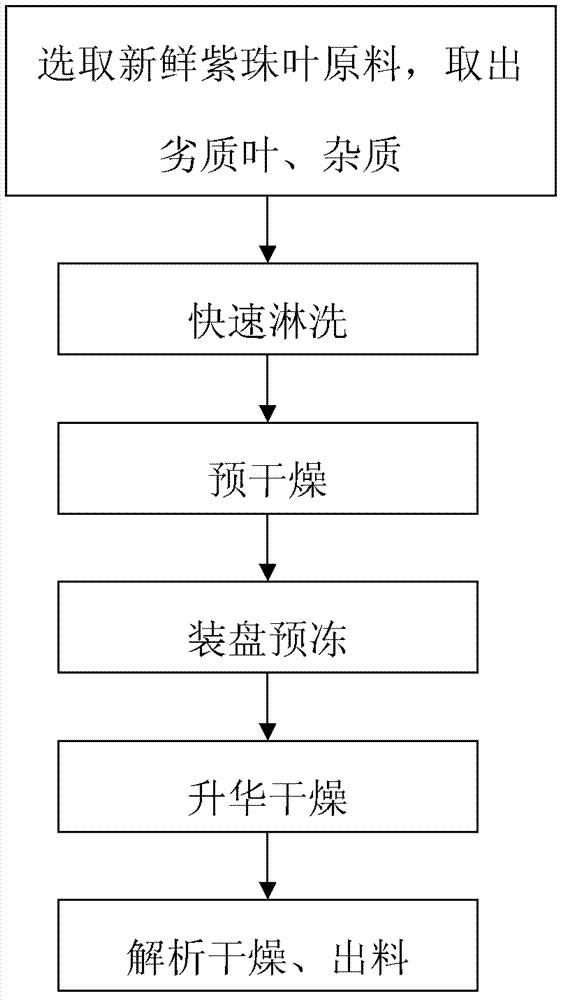

[0031] Such as figure 1 As shown, select fresh raw materials of Zizhu leaves, remove impurities such as branches, inferior and dead leaves; quickly rinse; pre-dry Zizhu leaves to a water content of 70%; put the pre-dried Zizhu leaves Disk weight is 2.7kg / m 2 , thickness 2cm, gradually cool down for 2 to 3 hours and then pre-freeze at -20°C to -40°C; then vacuumize the system until the absolute pressure of the system is 100Pa, enter the heating program, maintain the vacuum degree at 55-65Pa, and raise the temperature of the shed to 65°C. Sublimation drying for 15 hours; then keep the temperature of the material at 35°C, and discharge the material after the water content reaches below 2%.

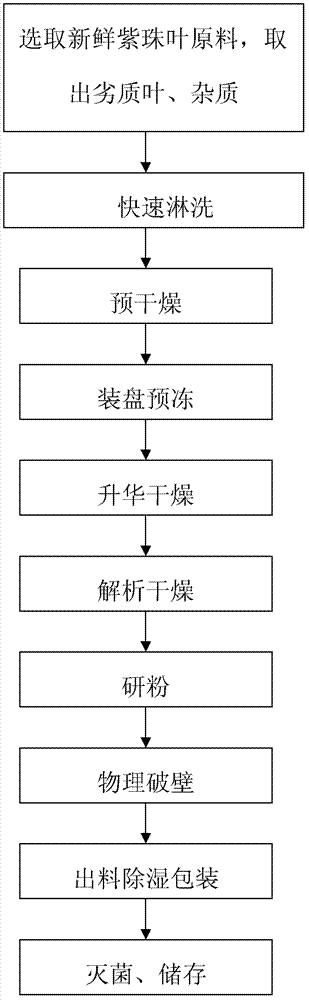

[0032] Such as figure 2 As shown, the purple pearl leaves after the aforementioned process steps are ground into powder, and physically broken after passing through a 100-mesh sieve. In a sealed...

Embodiment 2

[0035] Vacuum freeze-drying of Zizhu leaves was carried out by vacuum freeze-drying machine.

[0036] Select fresh raw materials of Zizhu leaves, remove impurities such as branches and dead leaves; rinse quickly; pre-dry Zizhu leaves to a water content of 60%; put the pre-dried Zizhu leaves on a plate, and the weight of the plate is 3kg / m 2 , thickness 2.5cm, gradually cool down for 2 to 3 hours and then pre-freeze at -20°C to -40°C; then vacuumize the system until the absolute pressure of the system is 100Pa, enter the heating program, keep the vacuum at 55-65Pa, and raise the temperature of the shed to 40°C , sublimation and drying for 15 hours; then keep the temperature of the material at 40°C, and discharge the material after the water content reaches below 3%.

[0037] After the above-mentioned steps, the purple pearl leaves are ground into powder and passed through a 100-mesh sieve to physically break the wall. In a sealed and dry state, two supersonic airflows are used ...

Embodiment 3

[0039] Vacuum freeze-drying of Zizhu leaves was carried out by vacuum freeze-drying machine.

[0040] Select fresh raw materials of Zizhu leaves, remove impurities such as branches and dead leaves; rinse quickly; pre-dry Zizhu leaves to a water content of 65%; put the pre-dried Zizhu leaves on a plate, and the weight of the plate is 3.5kg / m 2 , thickness 3cm, gradually cool down for 2 to 3 hours and then pre-freeze at -20°C to -40°C; then vacuumize the system until the absolute pressure of the system is 100Pa, enter the heating program, the vacuum degree reaches 65Pa, the temperature of the shed is raised to 60°C, and sublimation drying 12 hours; keep the temperature of the material at 50°C, and discharge the material after the water content reaches below 3%.

[0041] After the above-mentioned steps, the purple pearl leaves are ground into powder and passed through a 100-mesh sieve to physically break the wall. In a sealed and dry state, two supersonic airflows are used to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com