Gloves on-line automatic demoulding machine and its glove demoulding mechanism

A technology of demolding mechanism and glove, applied in the field of glove demolding mechanism, can solve the problems such as the inability to guarantee the parallelism gap of two sets of bearings, the inability to guarantee the flatness well, and the impact on the yield of the formed gloves, and the installation can be achieved. Simple, improve yield, and ensure the effect of assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

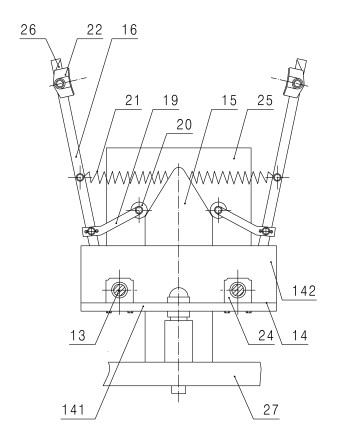

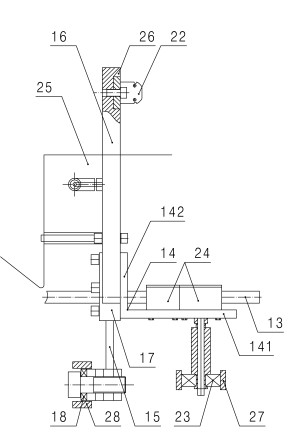

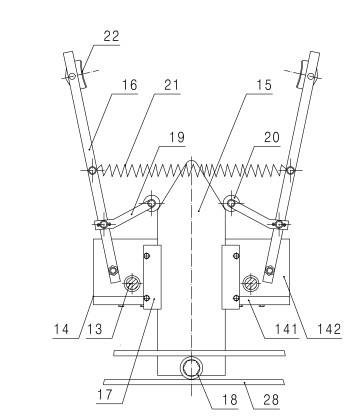

[0019] Such as figure 1 As shown, the glove demoulding mechanism of the present invention includes: an L-shaped base plate 14, the L-shaped base plate 14 includes a horizontal plate 141 and a vertical plate 142 fixed together, and the back side of the horizontal plate 141 is provided with a guide bearing 23 through a supporting frame , the back side of the vertical plate 142 is slidably provided with a wedge 15, such as image 3 As shown, the specific arrangement method is as follows: a pair of cooperating chute seats 17 are provided on the back side of the vertical plate 142, and cooperating chute slots are provided on the inner side surfaces of the pair of chute seats 17, and the slant The wedge 15 is movably arranged in the pair of chutes; the bottom of the wedge 15 is provided with a wedge bearing 18, and a pair of rocker arms 16 are movably hinged on both sides of the vertical plate 142, and a return spring 21 is arranged between the pair of rocker arms 16, The top of ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com