Cationic cellulose with high substitution degree and preparation method and application thereof

A cationic cellulose, high degree of substitution technology, applied in the field of functionalization reaction of natural polysaccharide polymers, can solve the problems of long dissolution and reaction time, complex intermediate treatment process, high technical cost, and eliminate intermediate pressing or washing and alkali removal. steps, reducing material consumption and energy consumption, and simplifying the effect of the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11

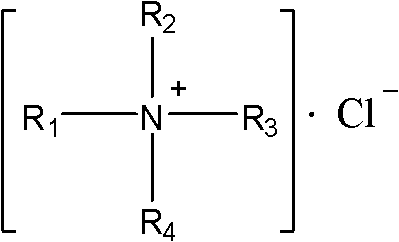

[0037] Using natural cotton linters as raw materials to prepare cationic cellulose with a high degree of substitution, the specific operation steps are as follows, and the differences between the examples are shown in Table 1:

[0038] (1) Activation: Mix cellulose with isopropanol I under normal temperature and pressure, stir to make the cellulose dispersed evenly, then add 30% sodium hydroxide aqueous solution and auxiliary activator sodium borate (Na 2 B 4 O 7 ·10H 2 O), perform activation reaction according to the pretreatment conditions in column 7 of Table 1 to obtain liquid A;

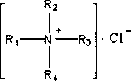

[0039] (2) Cationization reaction: Add isopropanol II and cationic etherification agent (3-chloro-2-hydroxypropyltrimethylammonium chloride, CTA, 50% mass fraction aqueous solution) into liquid A, according to The cationization reaction was carried out under the reaction conditions in the 7th column of Table 1 to obtain Liquid B;

[0040] (3) Post-treatment: Cool liquid B to room temperature, filter, w...

Embodiment 1

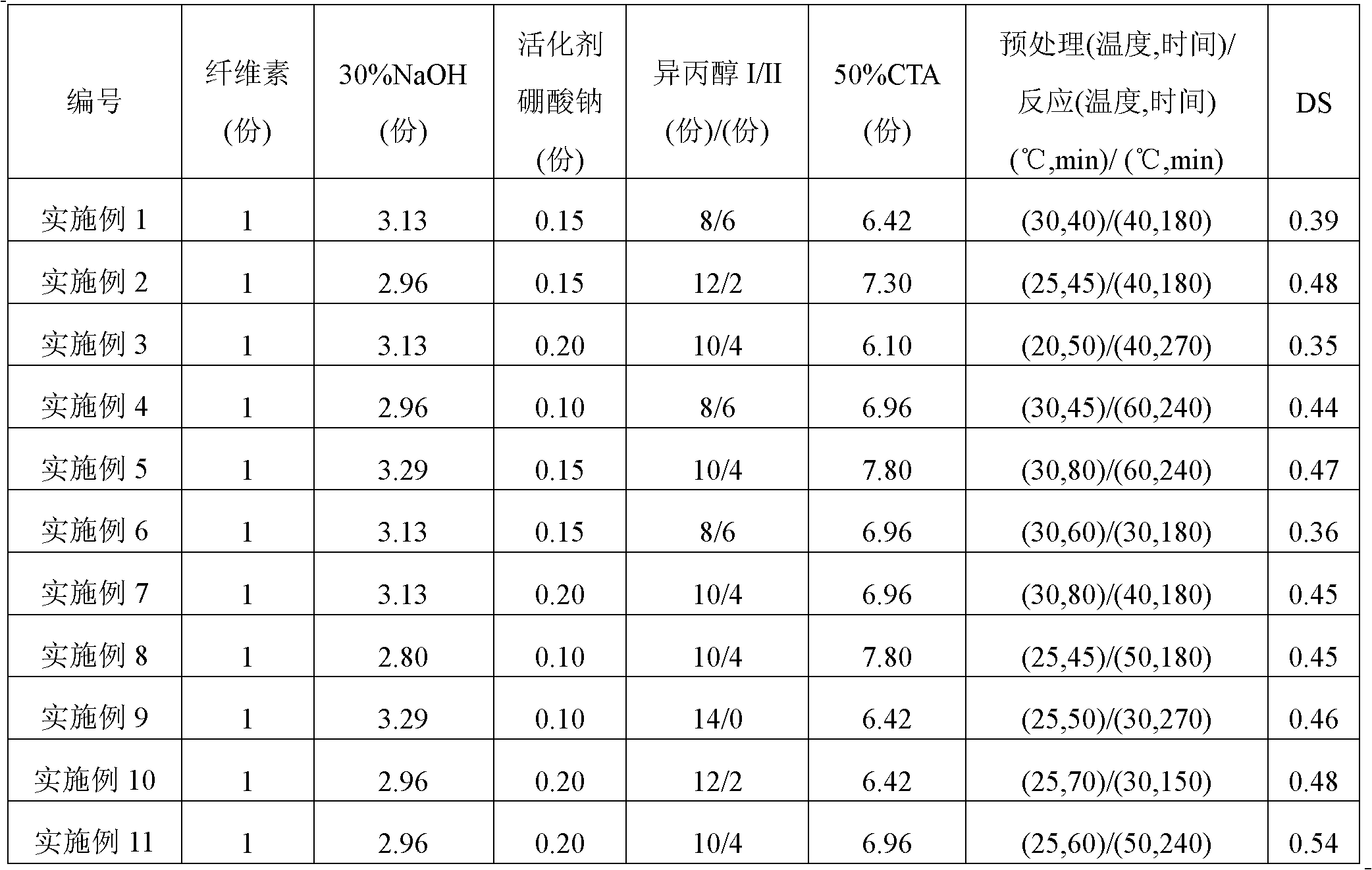

[0047] The basic operation process of Examples 12-17 is the same as that of Example 1. The changes made are only adjustments to the type of etherifying agent and activator used in Example 1, the amount of each substance added, and the reaction conditions. Among them, Example 12 and The cationic etherifying agent in 15 is glycidyl dodecyl dimethyl ammonium chloride, and the cationic etherifying agent in Examples 13 and 17 is glycidyl tetradecyl dimethyl ammonium chloride, The cationic etherifying agent in Examples 14 and 16 is glycidyl benzyl dimethyl ammonium chloride, as shown in Table 2.

[0048] Table 2 The proportions of reactants and test results of each embodiment

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com