An underwater mud pump device for suction dredging ships

A technology for mud pumps and ships, which is applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of affecting economic benefits, increasing ship construction costs, and increasing parameters, so as to save the frequency conversion drive system, shorten the transmission distance, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

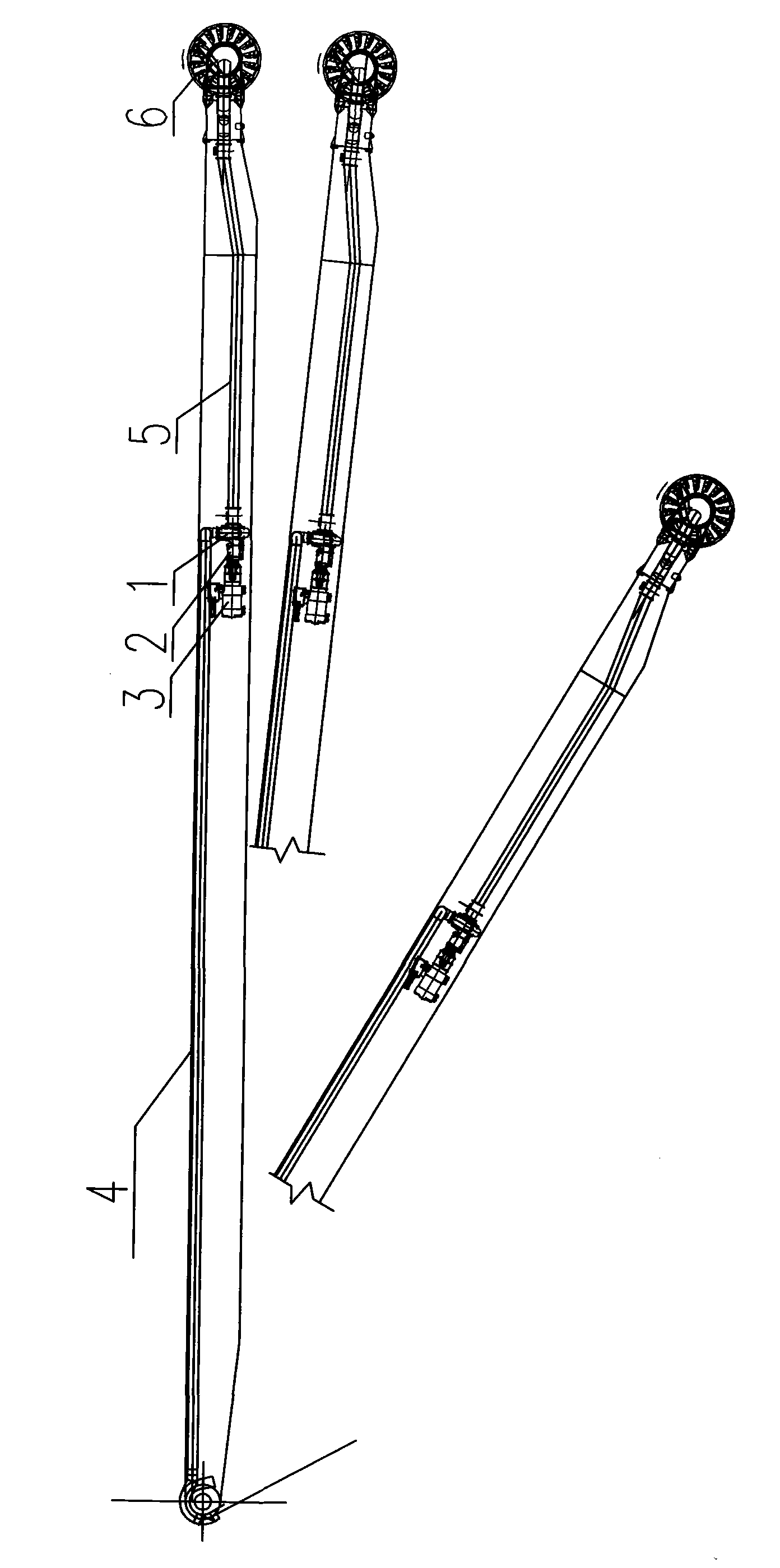

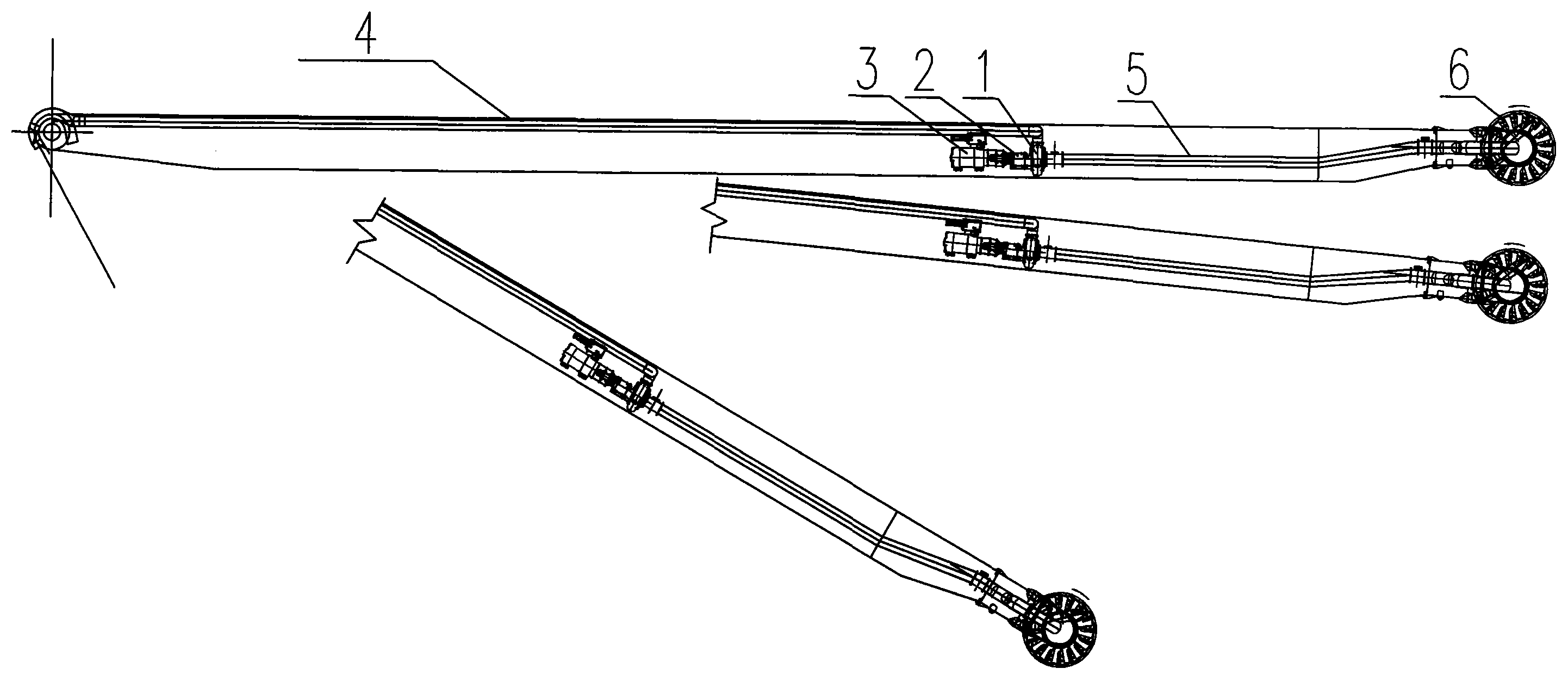

[0007] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 , The underwater mud pump device described in this embodiment includes a mud pump 1, a waterproof motor 2, and an elastic coupling 3, wherein the waterproof motor 2 is installed on the mud suction frame 4, and is connected to one end of the elastic coupling 3 , the other end of the elastic coupling 3 is connected to the mud pump 1 installed on the mud suction frame 4 to provide power for the mud pump 1; the mud pump 1 is connected to the cutting device 6 through the mud suction pipe 5. After adopting the above solution, the waterproof motor 2 directly drives the underwater mud pump 1 through the elastic coupling 3 . Compared with the traditional submerged mud pump device, the reduction gearbox and transmission shafting are reduced. This scheme not only saves the expensive frequency conversion dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com