Empty/full load self-adaptive pressure compensation oil-pneumatic suspension cylinder

A technology of pressure compensation and oil-air suspension, which is applied in the direction of fluid pressure actuation devices, can solve the problems of lack of integration functions, etc., and achieve the effects of increasing stability and reliability, improving technical level, and good damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

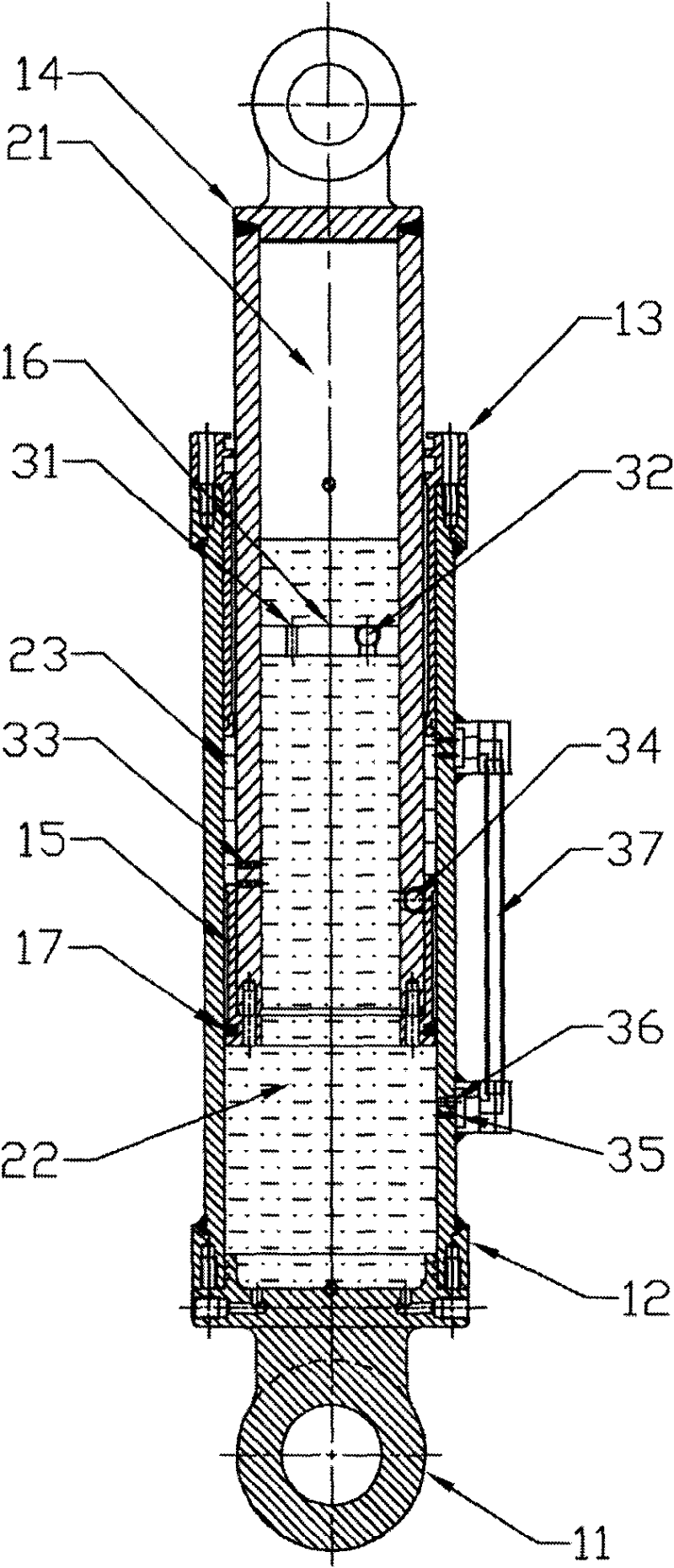

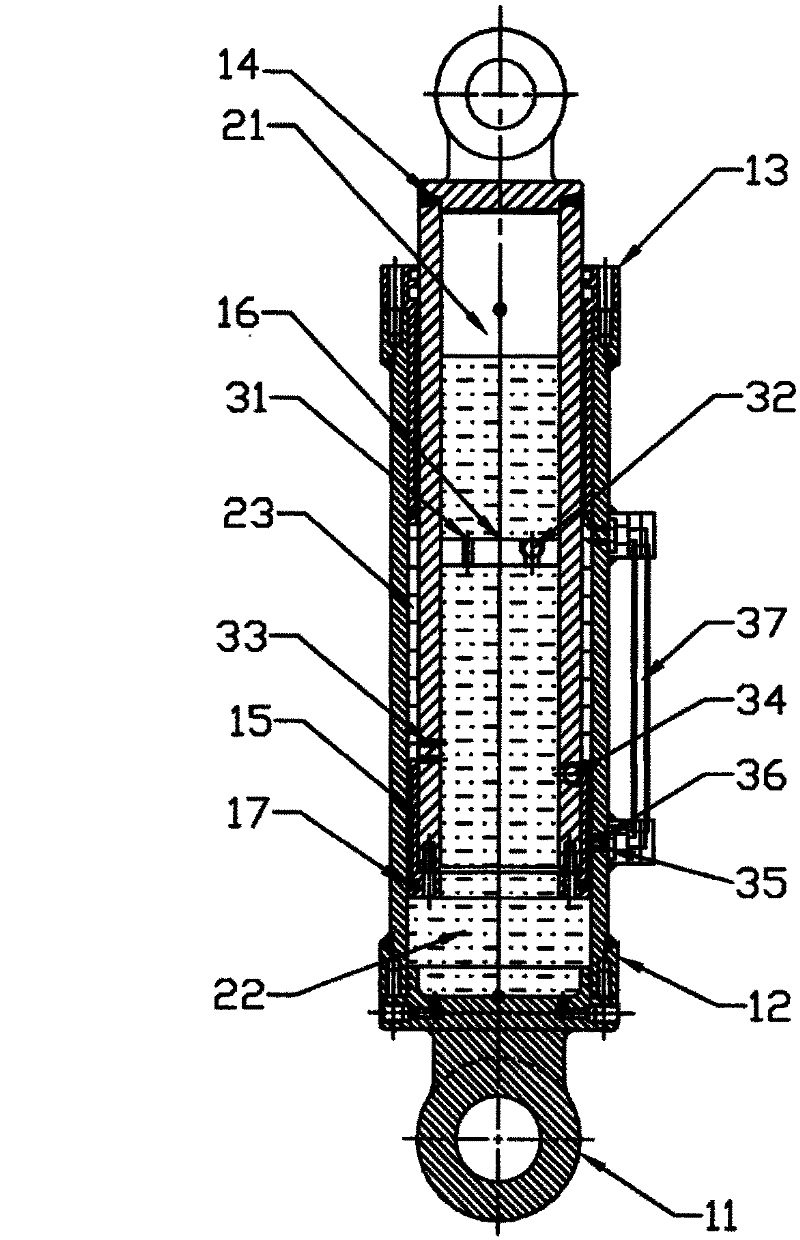

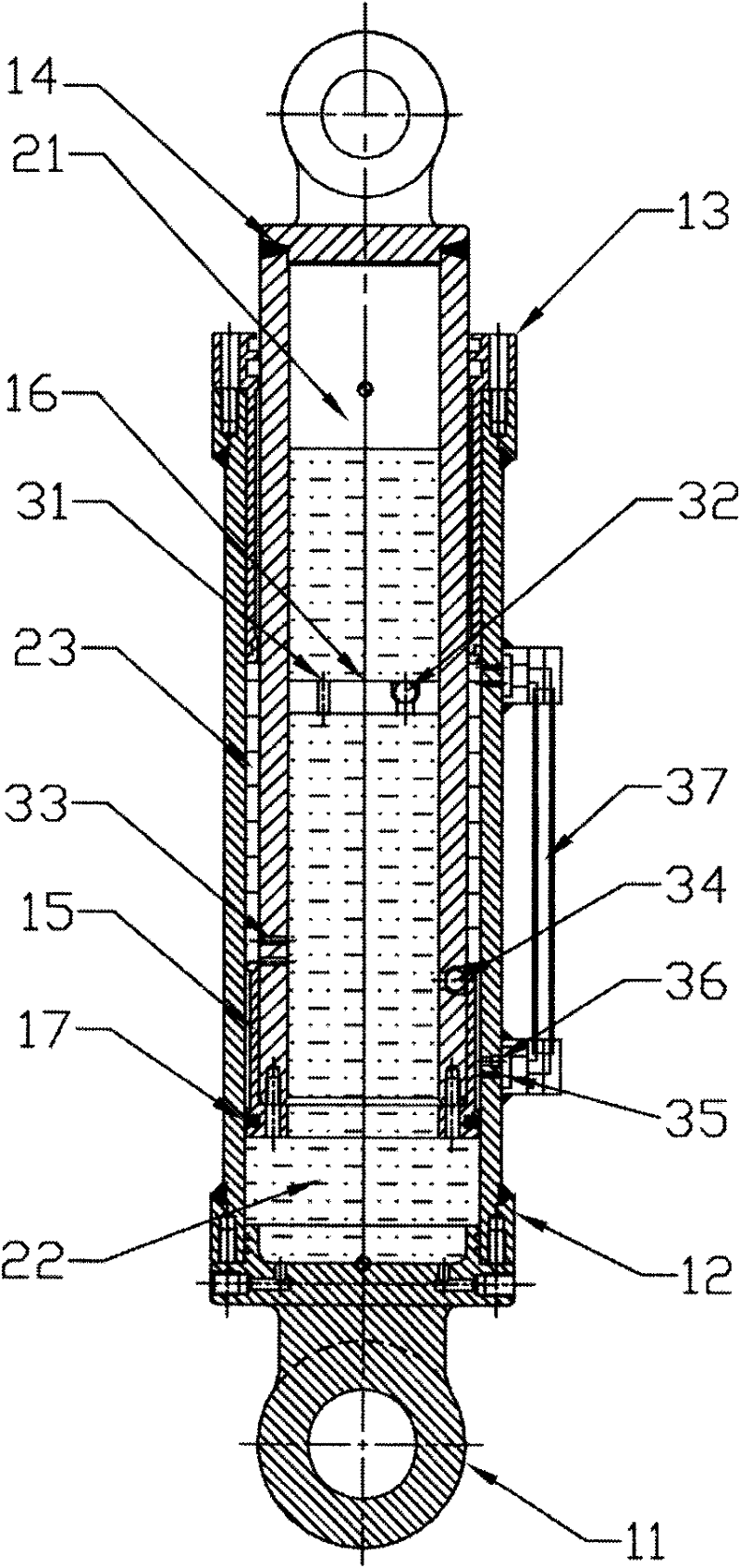

[0014] The present invention comprises a cylinder head 11, a cylinder barrel 12, a sealing seat ring 13, a piston rod 14, a piston 15, and a stopper 16; three oil chambers, an upper oil chamber 21, a lower oil chamber 22, and an auxiliary oil chamber 23 are arranged in the suspended cylinder. Inside the cylinder 12, the stopper 16 is fixedly connected to the inner wall of the piston rod 14, and the stopper 16 is provided with a damping hole 31 and a one-way valve 32, which communicate with the upper oil chamber 21 and the lower oil chamber 22 to form an upper oil chamber 21 and the cylinder internal damping passage between the lower oil chamber 22; the piston rod 14 is at one end of the lower oil chamber 22, and the piston rod side wall between the piston 15 and the stopper 16 is provided with a damping hole 33 and a one-way valve 34 to communicate with the lower oil chamber. Cavity 22 and auxiliary oil chamber 23 form the internal damping passage between the lower oil chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com