The electromagnetic valve

A solenoid valve and valve seat technology, applied in the field of solenoid valves, can solve the problems of inconvenient installation, large size and high price, and achieve the effects of simple structure, easy installation and high cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

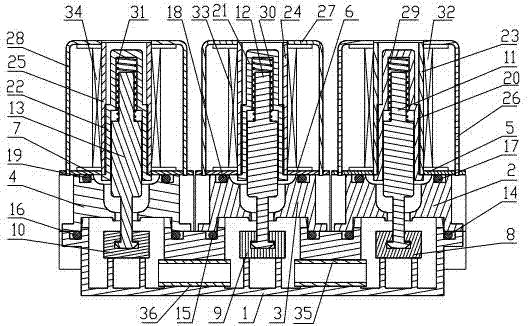

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

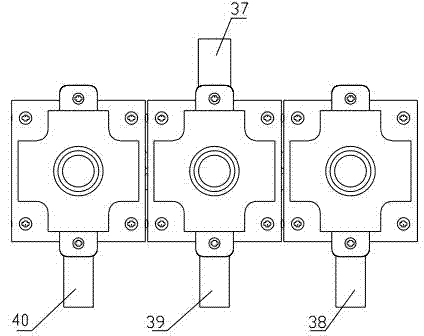

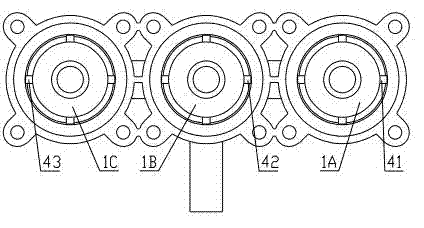

[0013] The present invention includes a lower valve seat 1 (including three solenoid valve bases 1A, 1B, 1C, different bases are connected through stainless steel pipes, 35, 36), upper valve seats 2, 3, 4, stainless steel pipes, 35, 36, Lower seat gaskets 14, 15, 16, upper seat gaskets 17, 18, 19, movable spools 11, 12, 13, plugs 8, 9, 10, springs 29, 30, 31, fixed spools 20, 21 , 22, sealing plates 5, 6, 7, coils 32, 33, 34, sleeves 23, 24, 25, upper casings 26, 27, 28, characterized in that the upper valve seats 2, 3, 4 are respectively Placed on the three solenoid valve bases 1A, 1B, 1C of the lower valve seat 1, positioned through the installation grooves 41, 42, 43 on the three solenoid valve bases 1A, 1B, 1C of the lower valve seat 1, and the upper valve seat 2 , 3, 4 and the inlet and outlet orifice pipes 37, 38, 39, 40 of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com