The electromagnetic valve

A solenoid valve and solenoid coil technology, applied in the field of solenoid valves, can solve the problems of high energy consumption and limited use of fluid regulating valves, and achieve the effects of reducing power consumption, reducing driving current, and avoiding mechanical failure and fatigue problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the following embodiments and accompanying drawings are only used to understand the present invention, but not to limit the present invention. The present invention can be implemented in various ways defined and covered by the claims.

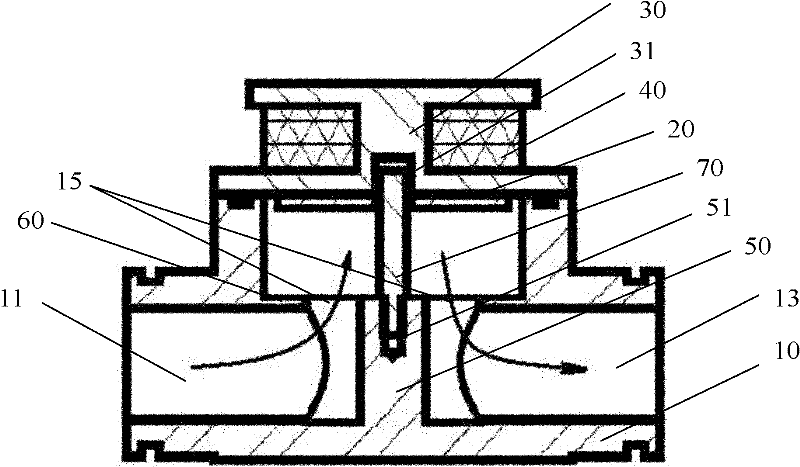

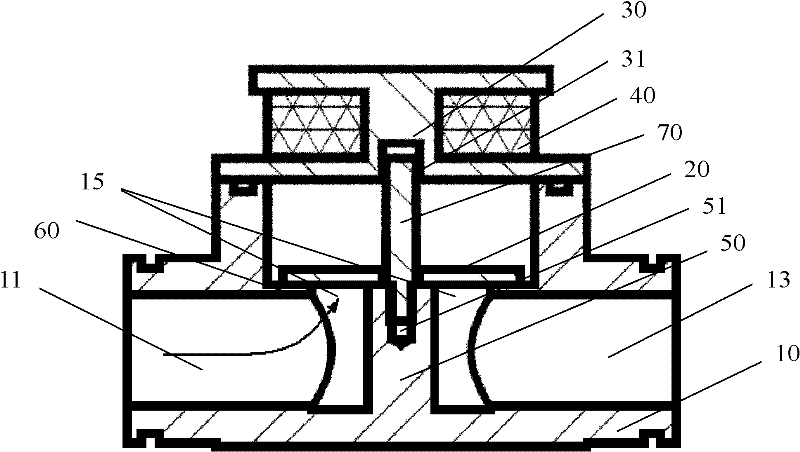

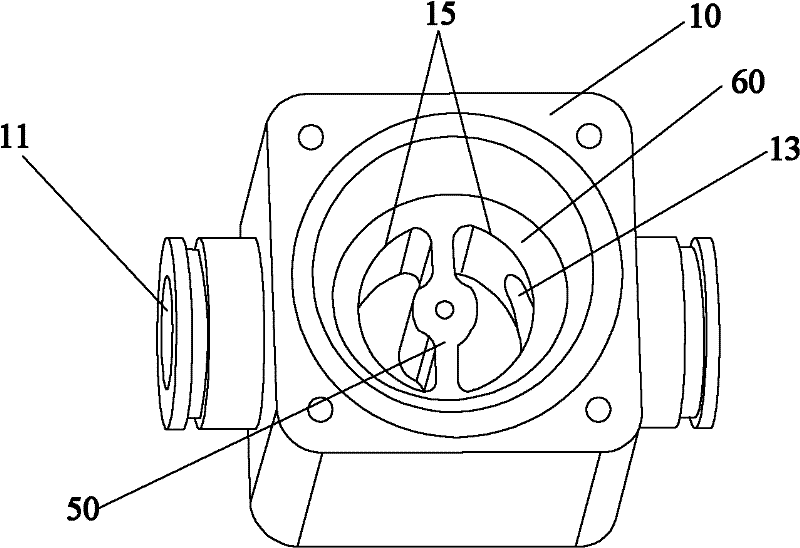

[0023] Such as figure 1 with figure 2 As shown, in a typical implementation of the present invention, the solenoid valve includes a valve seat 10, a valve core 20 and a valve cover 30, and the valve core 20 is movably arranged between the valve seat 10 and the valve cover 30 to form a In the inner cavity, at least one of the valve seat 10 or the valve cover 30 includes a magnetic material, and at least one is provided with an electromagnetic coil 40; the valve core 20 is a magnetized material. The solenoid valve applies electromagnetic force to the valve core through the electromagnetic field to drive the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com