An Improved Structure of Feed Distributor for Decanter Centrifuge

A decanter centrifuge and improved structure technology, applied in centrifuges and other directions, can solve the problems of inconvenience and inconvenience of on-site replacement, and achieve the effects of small space, convenient maintenance and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

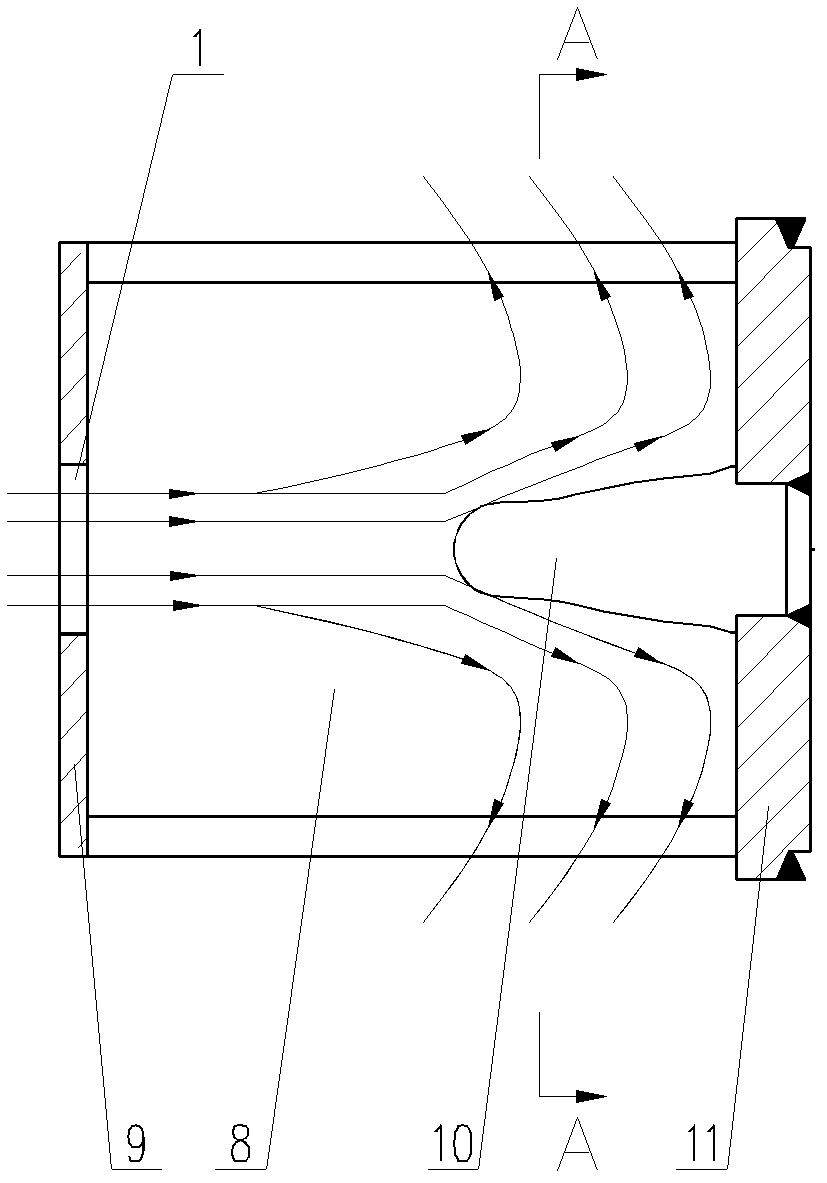

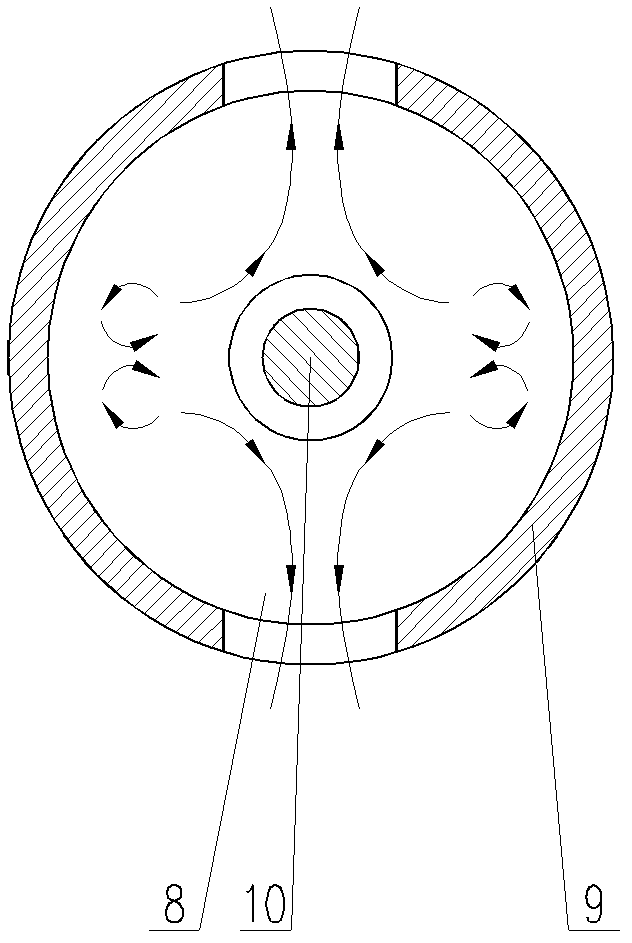

[0039] The present invention will be further described below in conjunction with the accompanying drawings, where the direction of the arrow in the figure is the flow direction of the floc material.

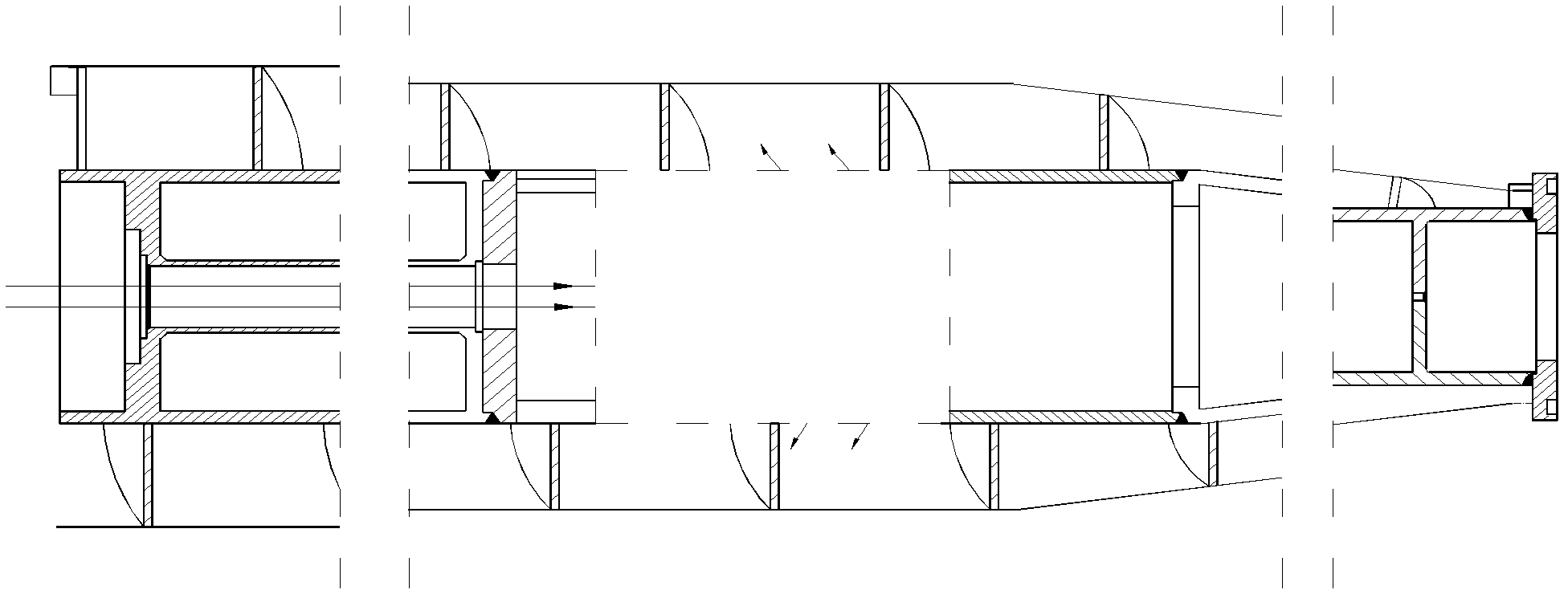

[0040] figure 1 The position of the dotted box in the middle is the assembly position of the feed distributor in the decanter centrifuge. The floc material enters from the left end of the feed distributor and is discharged from the upper and lower outlets.

[0041] Figure 2~3 Among them, the horizontal drum body 9 has a circular distribution cavity 8 inside, the right end of the barrel body 9 is an open end, covering the end cover 11, the left end is a closed end, and a feed hole 1 is opened in the center to communicate with the distribution cavity 8 , The top and bottom of barrel body 9 are vertically provided with discharge ports, which communicate with distribution chamber 8. The right end of the distribution chamber 8 is equipped with a distributor head 10 facing the feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com