Blade-type lock closed and opened under control of lifting of brake rod, and key

A lifting control and brake lever technology, applied in the field of blade-type mechanical locks, can solve problems such as high mutual opening rate, lock failure rate and unsatisfactory safety performance, wrong lock cylinder opening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

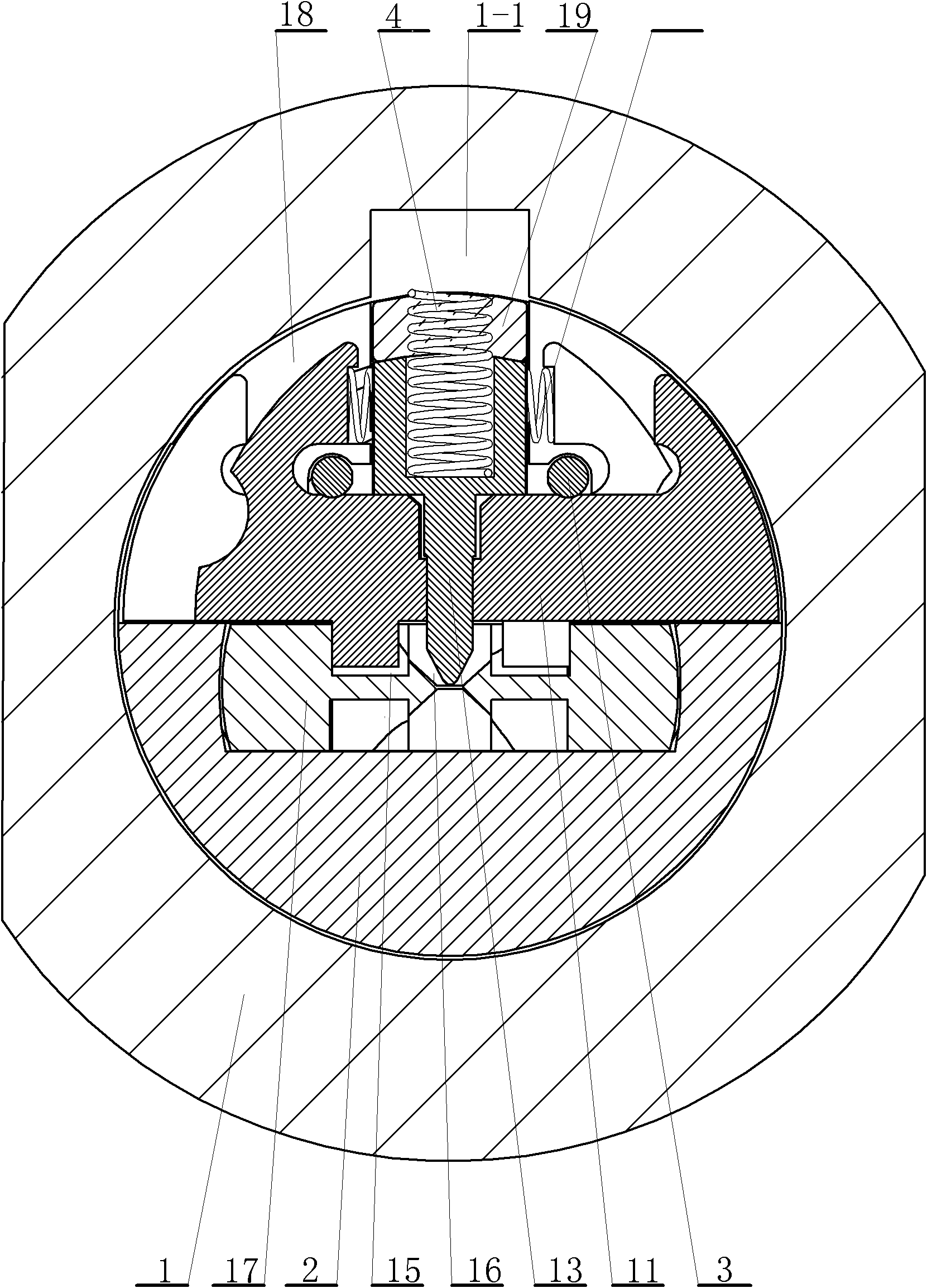

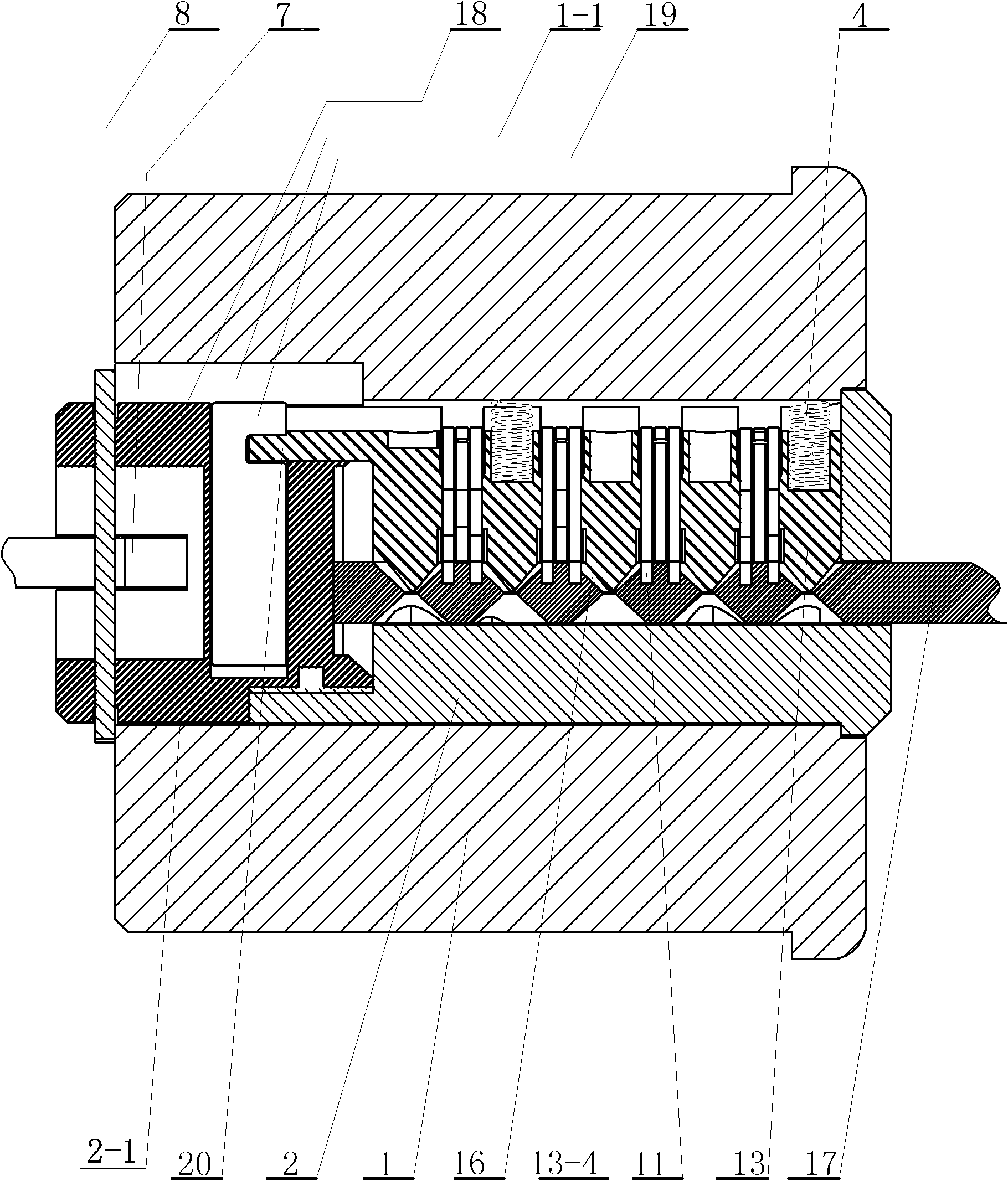

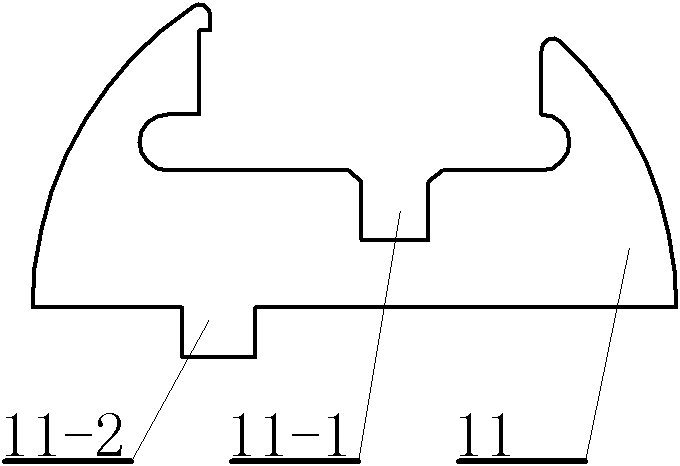

[0027] According to each drawing, each component of the present invention is manufactured and then assembled. Tell about the structural situation of each parts here respectively, outside one side of lock core 2 along radial excavation 1-8 waist-shaped grooves 10, in waist-shaped groove 10, assemble semicircle-arc-shaped blade 11 three pieces, in and waist-shaped Groove 10 excavates bumper groove 12 vertically radially, and bumper groove 12 overlaps with waist-shaped groove 10 together. Drill a key groove 14 on the front end face of the lock core 2 . Drill the rear end round hole 2-1 at the rear end of the lock core 2, and dig two spacer slots 21 symmetrically on the outer circular surface of the lock core 2 rear end. Blade 11 of the present invention is a semicircular arc shape, and a concave groove 11-1 is dug on the support beam frame in the middle, and a rectangular parallelepiped moving column 11-2 is arranged at the bottom of the support beam frame, and the concave groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com