Power station condensate pump depth frequency conversion system

A technology of condensate pump and frequency conversion system, applied in the field of frequency conversion system, can solve the problems of low operation efficiency and high energy consumption of the condensate pump, achieve significant energy saving effect, improve regulation quality, and promote stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

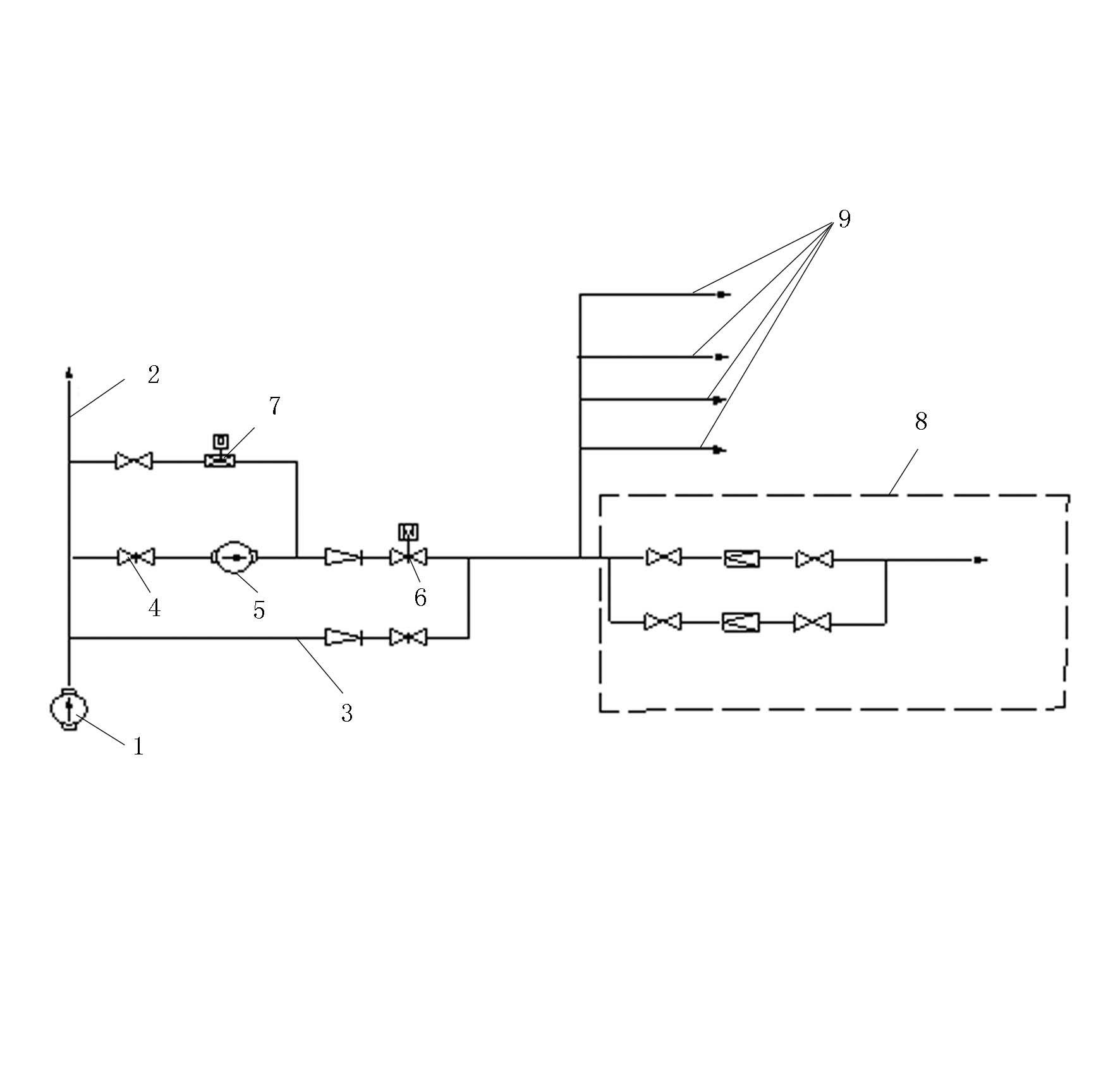

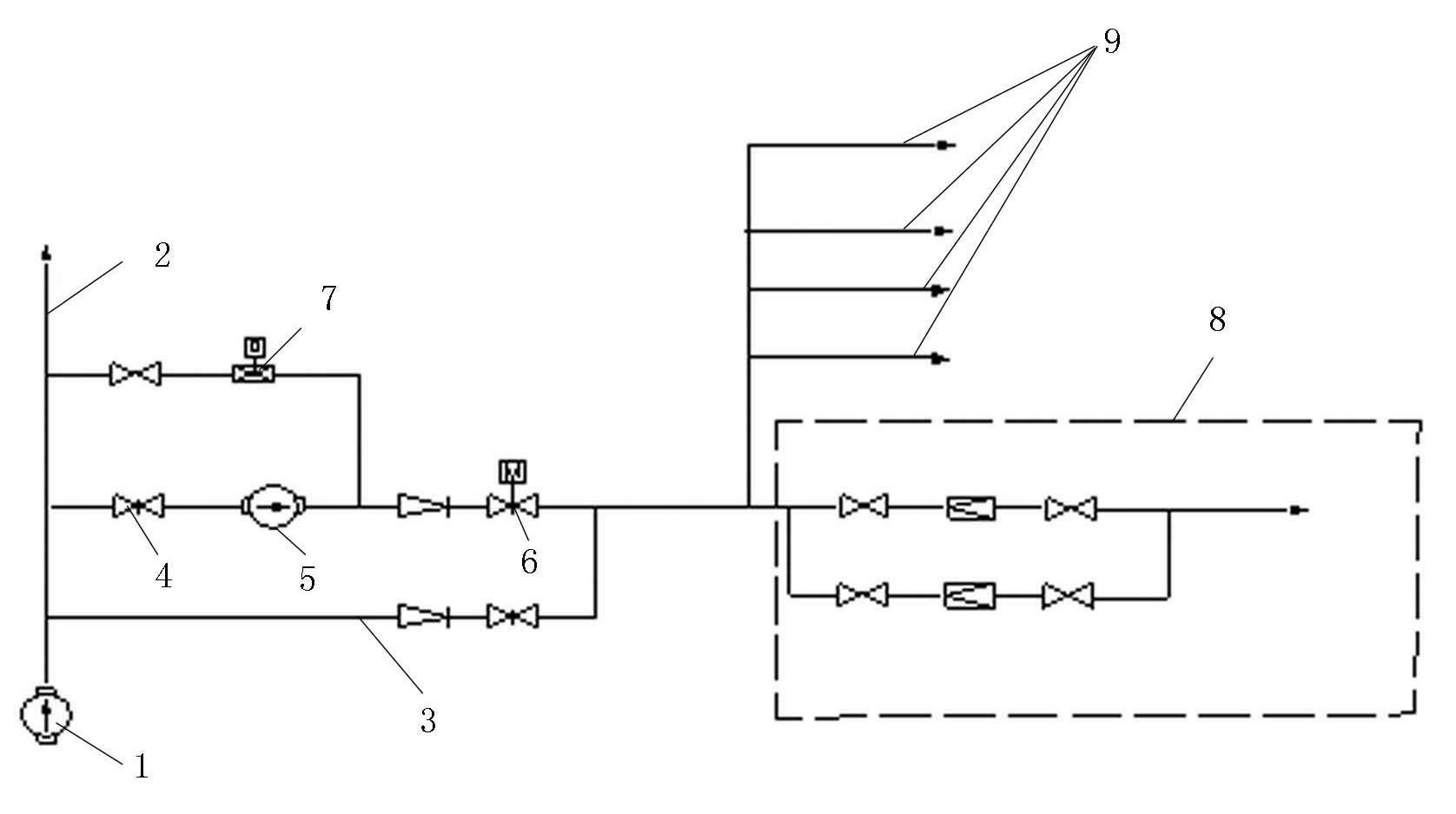

[0025] Including the sealing water system 8 and the condensate jellyfish pipe 2, an inlet pipeline is introduced on the pipeline of the condensate jellyfish pipe 2, a booster pump 5 is arranged on the inlet pipeline, and the inlet isolation valve 4 is arranged between the condensate jellyfish pipe 2 and the booster pump 5 In between, the outlet of the inlet pipeline is provided with a recirculation circuit for adjusting the outlet pressure of the booster pump, the pipeline of the recirculation circuit is connected to the condensate jellyfish pipe 2, and the outlet of the booster pump 5 is provided with a check valve and an outlet in turn. Isolation valve 6, check valve and outlet isolation valve 6 are used together with inlet isolation valve 4 and outlet pressure regulating valve 7 to reliably isolate the system when needed. Fluid pressure transmitters are installed on the inlet and outlet pipelines for system protection and monitoring of operating parameters.

[0026] The out...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap