Internal leakage insert snap-in end face seal safety valve for electric water heater

A technology for end face sealing and electric water heaters, which is applied in the direction of multi-way valves, valve devices, engine components, etc., can solve the problems of low assembly efficiency, complicated production process, and difficult quality assurance, and achieve both stability and economy, and improve Effects of Reliability and Manufacturing Cost Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

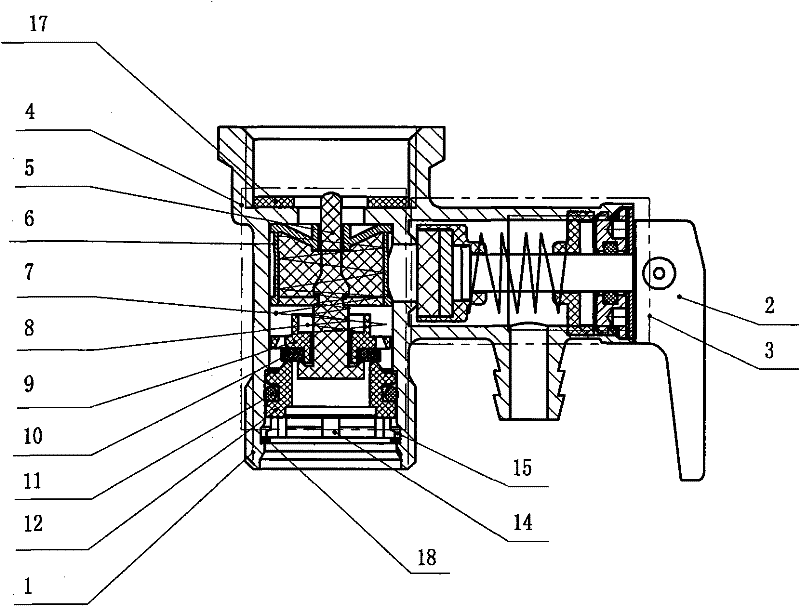

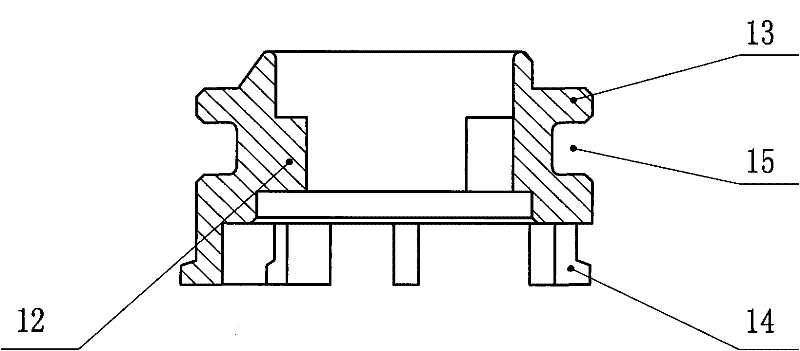

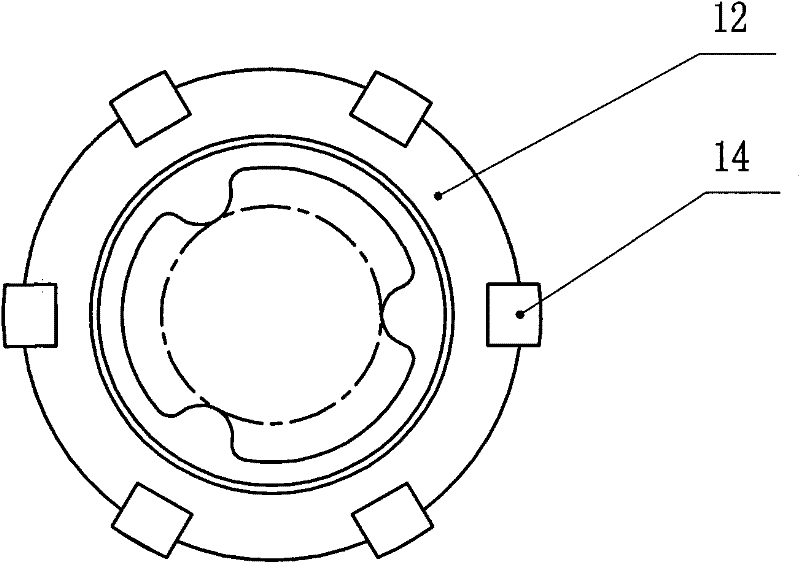

[0013] Embodiment 1: as figure 1 As shown, the internal leakage insert snap-in type end face seal electric water heater safety valve includes valve body 1, handle 2, external leakage body 3, internal leakage body 4 and flat gasket 17, internal leakage body 4 includes valve stem 5, with Filter card seat 6, water inlet spring 7, pressure spring 8, spring seat 9, reverse sealing gasket 10, O-ring 11 and internal leakage insert 12, such as figure 2 and image 3 As shown, the internal leakage insert 12 includes a reverse sealing seat 13 and a positioning foot 14, the positioning foot 14 is set under the reverse sealing seat 13, an O-ring groove 15 is provided on the reverse sealing seat 13, and the reverse sealing seat 13 Cooperate with the inner ring of the valve body 1, the O-ring 11 is set in the O-ring groove 15, and a groove 16 is provided under the reverse sealing seat 13 in the valve body 1, and the positioning foot 14 is snapped into the groove 16 for positioning. The nu...

Embodiment 2

[0014] Embodiment 2: as figure 1 As shown, the internal leakage insert snap-in type end face seal electric water heater safety valve also includes a circlip 18, the circlip 18 snaps into the groove 16, and is located under the positioning pin 14, and the number of positioning pins 14 is 60 , and evenly distributed below the reverse seal seat 13, the reverse seal seat 13 on the internal leakage insert 12 is integrated with the positioning foot 14, and its material is high-strength engineering plastics, such as polyoxymethylene, and the rest are the same as in embodiment 1.

Embodiment 3

[0015] Embodiment 3: The number of positioning feet 14 is 28, and they are evenly distributed under the reverse sealing seat 13, and the rest are the same as Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com