Large-scale solar heat collector with integrated heat collection and transportation and manufacturing method thereof

The invention relates to a technology of a solar thermal collector and a manufacturing method, which are applied in the field of solar thermal utilization, can solve the problems of high cost, large heat collecting area, low thermal energy conversion efficiency, etc., and achieve long service life, convenient use and high optical energy conversion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

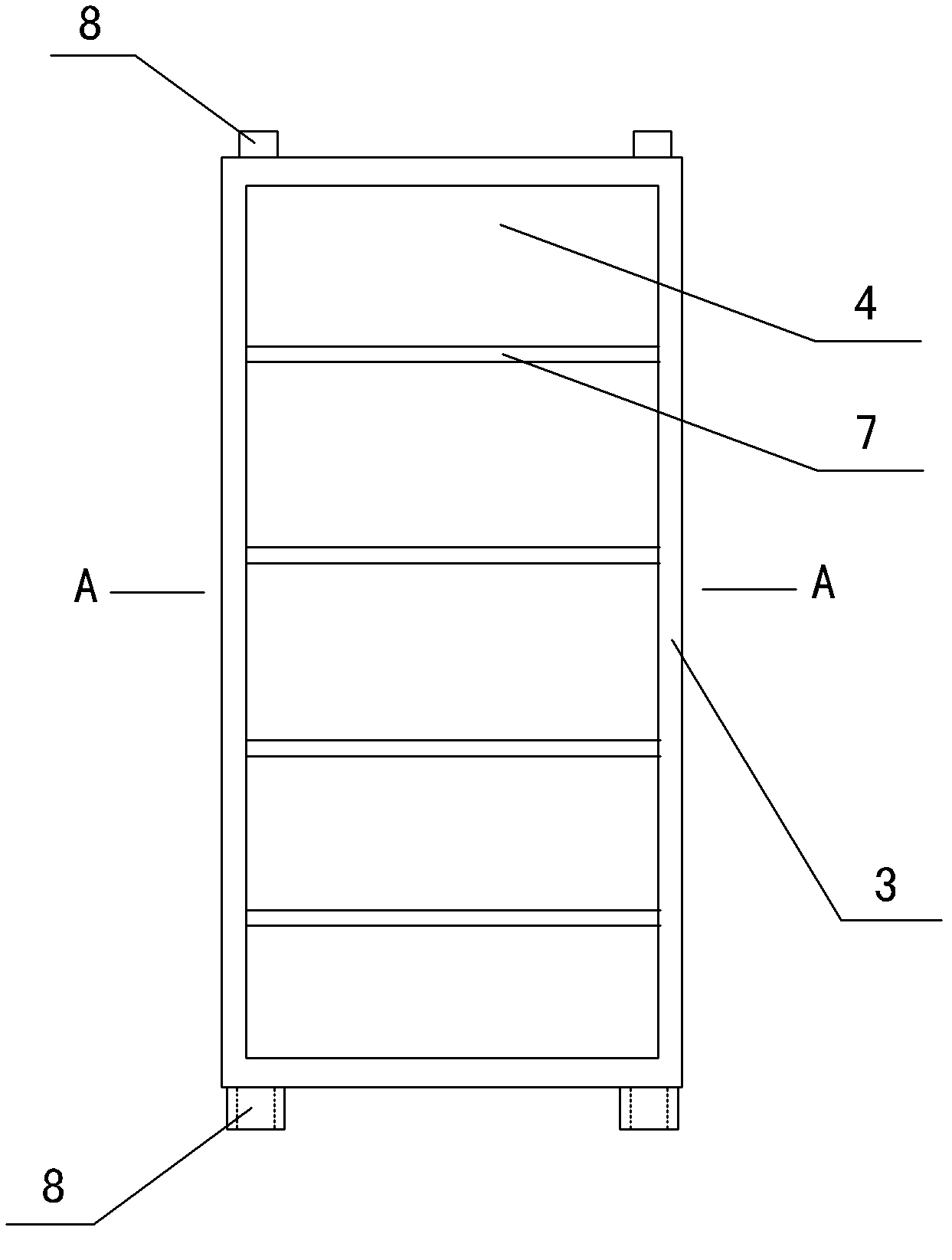

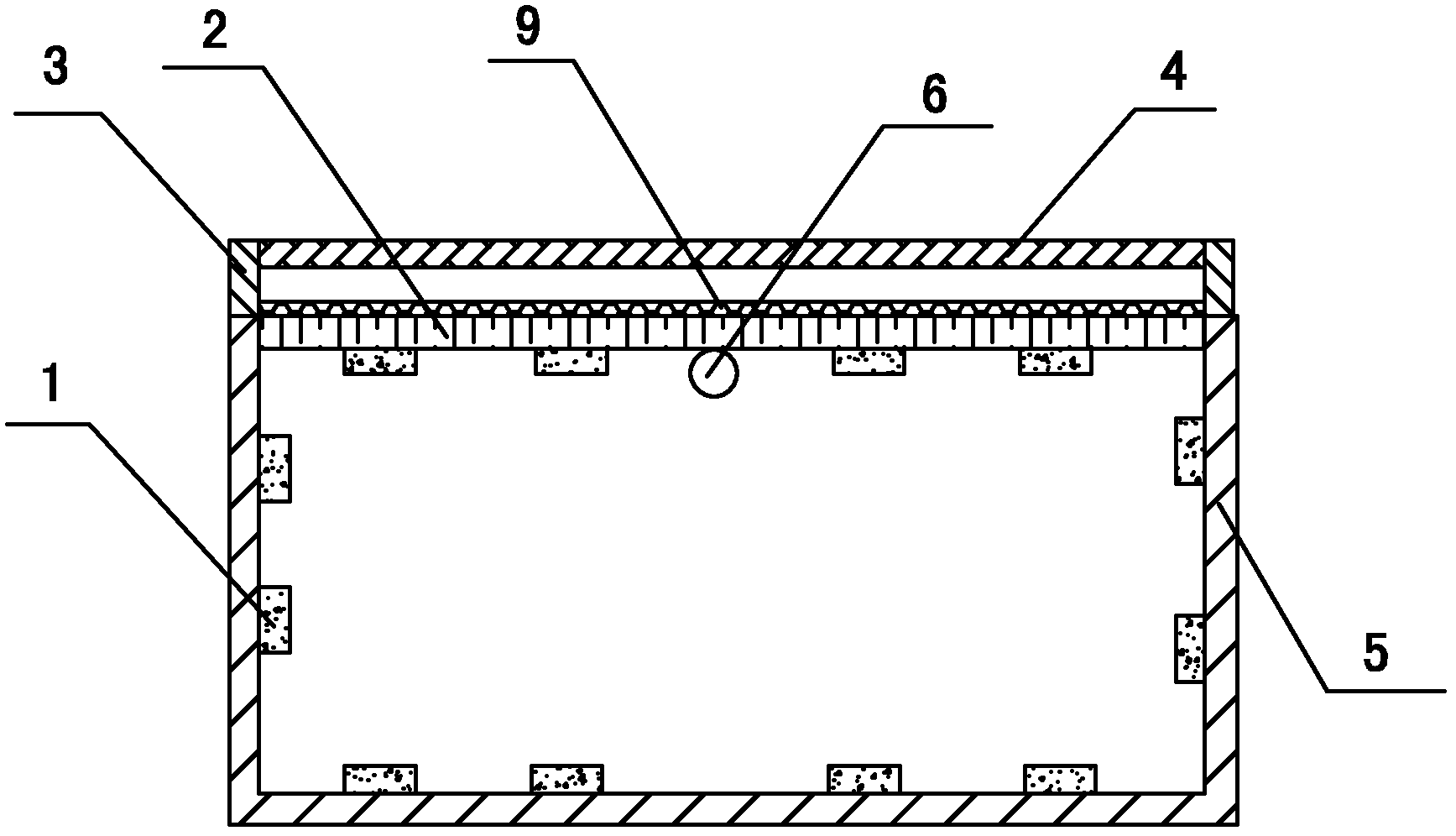

[0025] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0026] Such as Figure 1~2 As shown, the air duct structure support frame 1 is a cage structure, the cross section at both ends is an open structure, one side is a heat collecting surface, and the other sides are non-heat collecting surfaces, and the air heat exchange plate type flat tube is installed on the heat collecting surface 2. The sunny side of the air heat exchange plate type flat tube 2 is fixed with a selective heat-absorbing coating plate 9, and the outer keel 3 is fixed on the periphery of the heat collecting surface. The frame surrounded by the outer keel 3 is divided into four parts by the inner keel 7. A rectangular frame, the light-transmitting material plate 4 is installed in the rectangular frame surrounded by the outer keel 3 and the inner keel 7, and the non-heat collection surface of the air duct structure support frame 1 is installed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com