Detection and control process of equipment dedicated to electronic detonators

A detection control, electronic detonator technology, applied in the direction of offensive equipment, weapon accessories, fuzes, etc., can solve the hidden dangers of detonator safety and reliability, the inability to ensure the performance reliability and functional integrity of detonator products, etc., to improve detection efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The technical solutions of the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

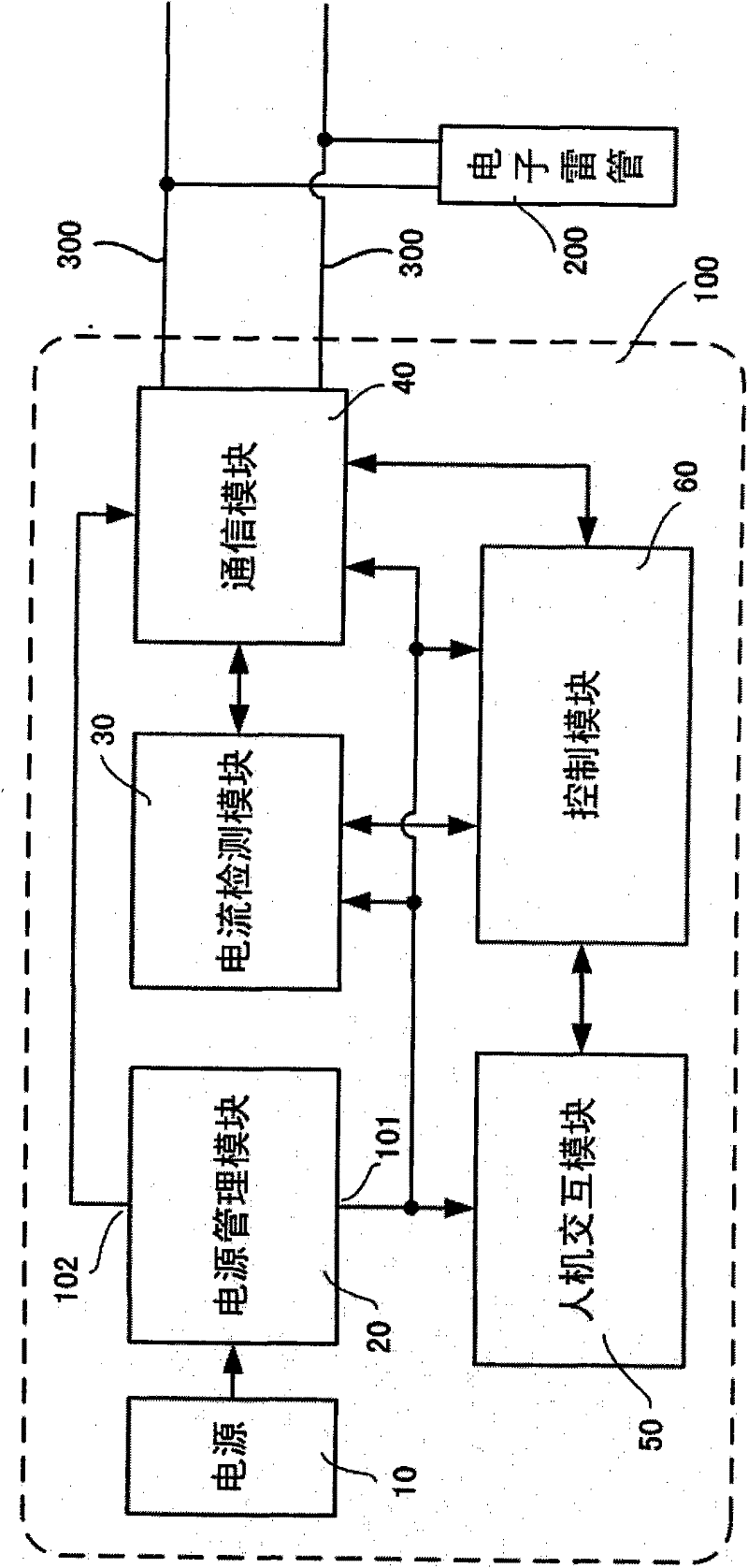

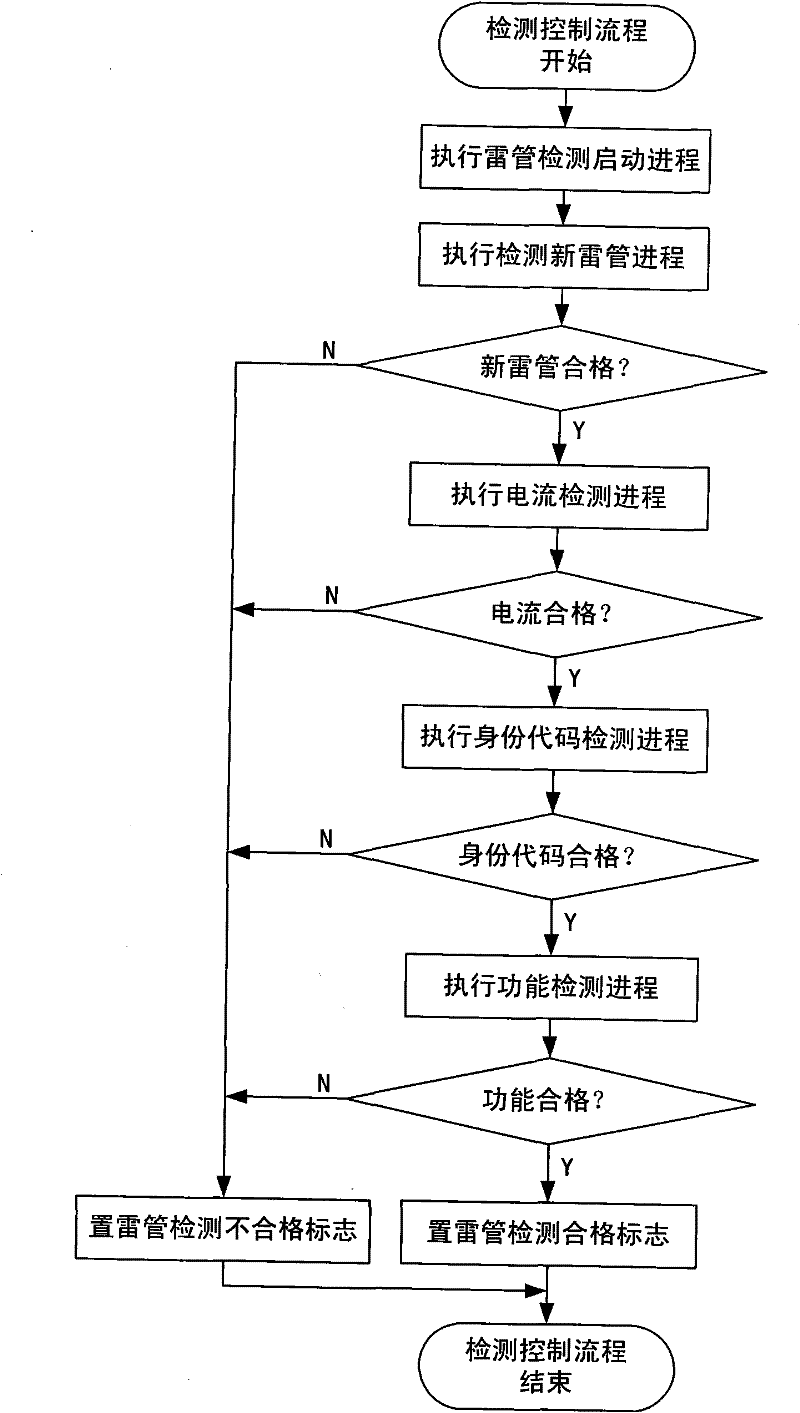

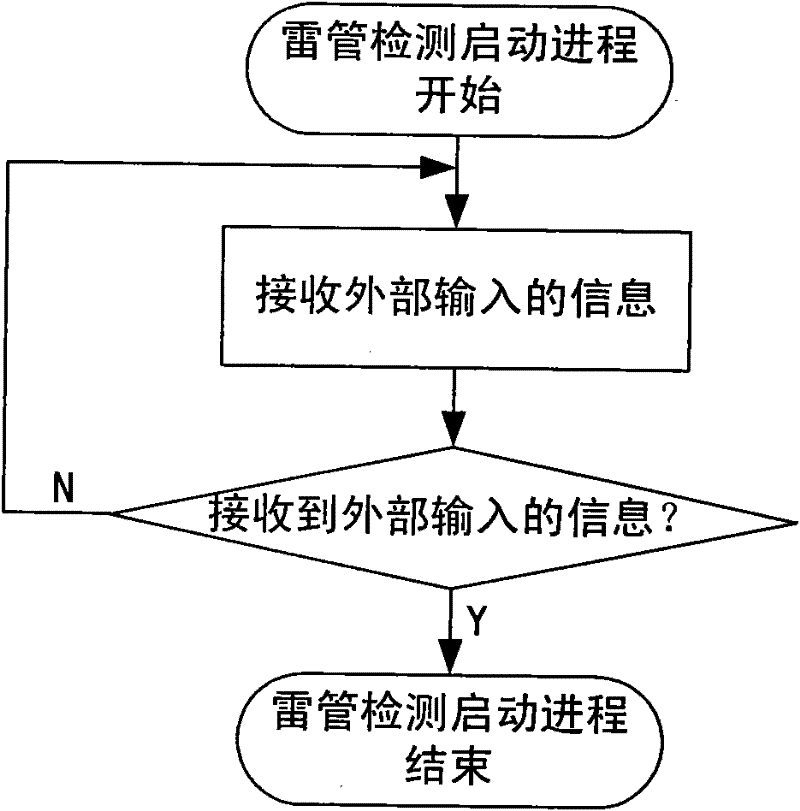

[0093] The equipment specially used for electronic detonators in the present invention is connected to the electronic detonator 200 through wires, and can be a special equipment for electronic detonator detection, or a special equipment for electronic detonator initiation, so as to meet the requirements of the production process and the use process of the detonator detection. different requirements of the process. As long as these devices can communicate with the electronic detonator, the detection control process of the present invention can be used to achieve the technical purpose of the present invention. As an example of this type of special equipment for electronic detonators, see figure 1 As shown, the device 100 is mainly composed of a power supply 10 , a power management module 20 , a current detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com