Self-calibration method of parallel robot

A robot and self-calibration technology, which is applied in the field of robots, can solve the problems of harsh installation conditions, difficult station layout of measuring equipment, and high operation requirements, and achieve the effects of easy installation accuracy, low calibration environment requirements, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

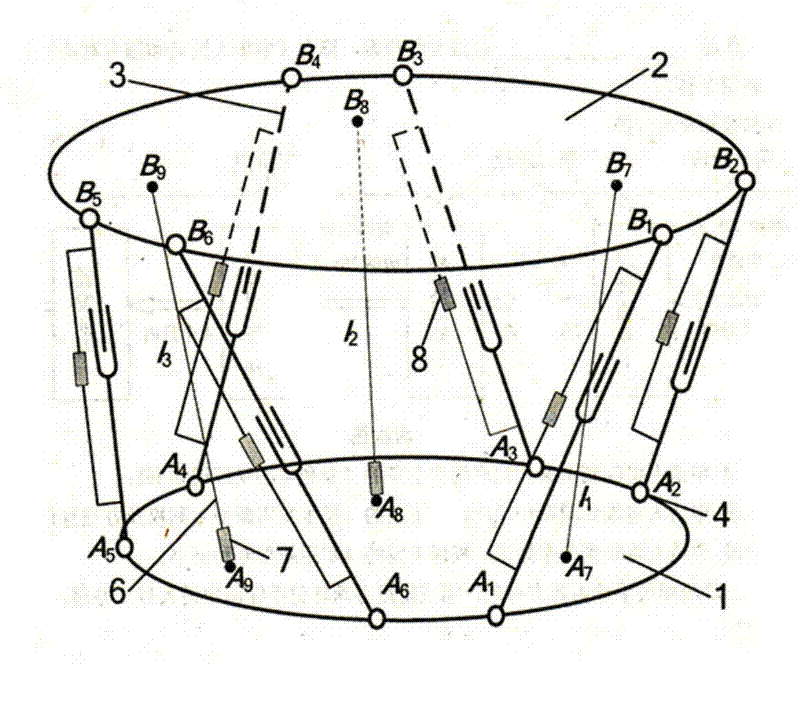

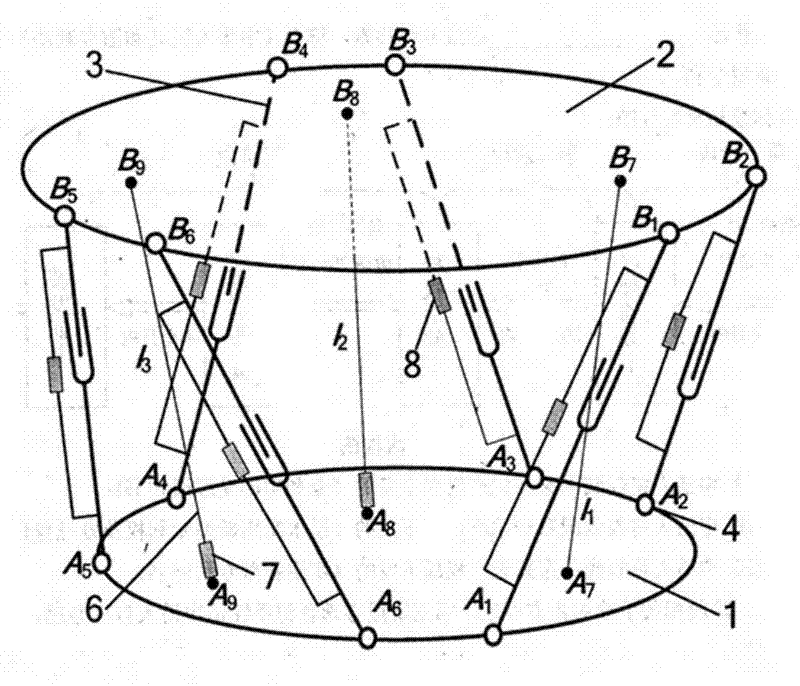

[0018] In conjunction with the accompanying drawings, the parallel robot self-calibration method of the present invention will be described in detail by taking it as an example.

[0019] Such as figure 1 As shown, the parallel robot involved in the present invention consists of a fixed platform 1, a moving platform 2, and a drive branch 3 ( A 1 B 1 , A 2 B 2 ,..., A 6 B 6 ) and hinges 4 and 5 (Hooke hinges or spherical hinges) connecting each branch to the fixed and moving platforms; three measurement branches 6 ( A 7 B 7 , A 8 B 8 , A 9 B 9 ), the two ends of which are respectively consolidated with the fixed and moving platforms (can be threaded or welded, and the position is arbitrary), and each branch is equipped with a rope sensor 7; the mobile pair of each driving branch of the parallel robot is installed Displacement sensor 8.

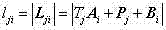

[0020] Corresponding to a specific pose, the relationship equation between the length of the 6 driving branches and 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com