Defect detection device, defect repair device, defect detection method

A defect detection and defect technology, which is applied in the direction of optical test defects/defects, optics, instruments, etc., to achieve the effects of reducing production costs, shortening production periods, and low costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

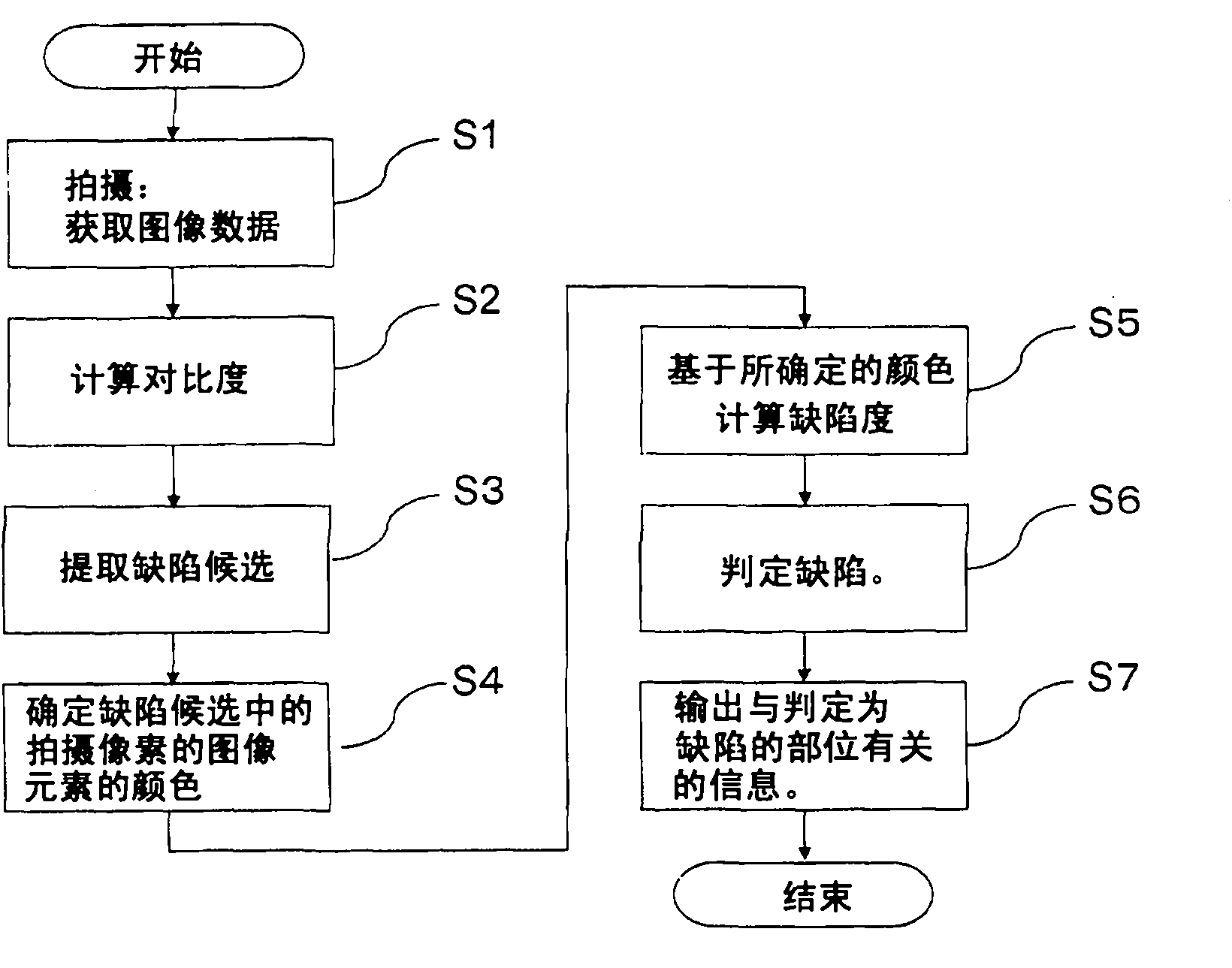

Embodiment 1

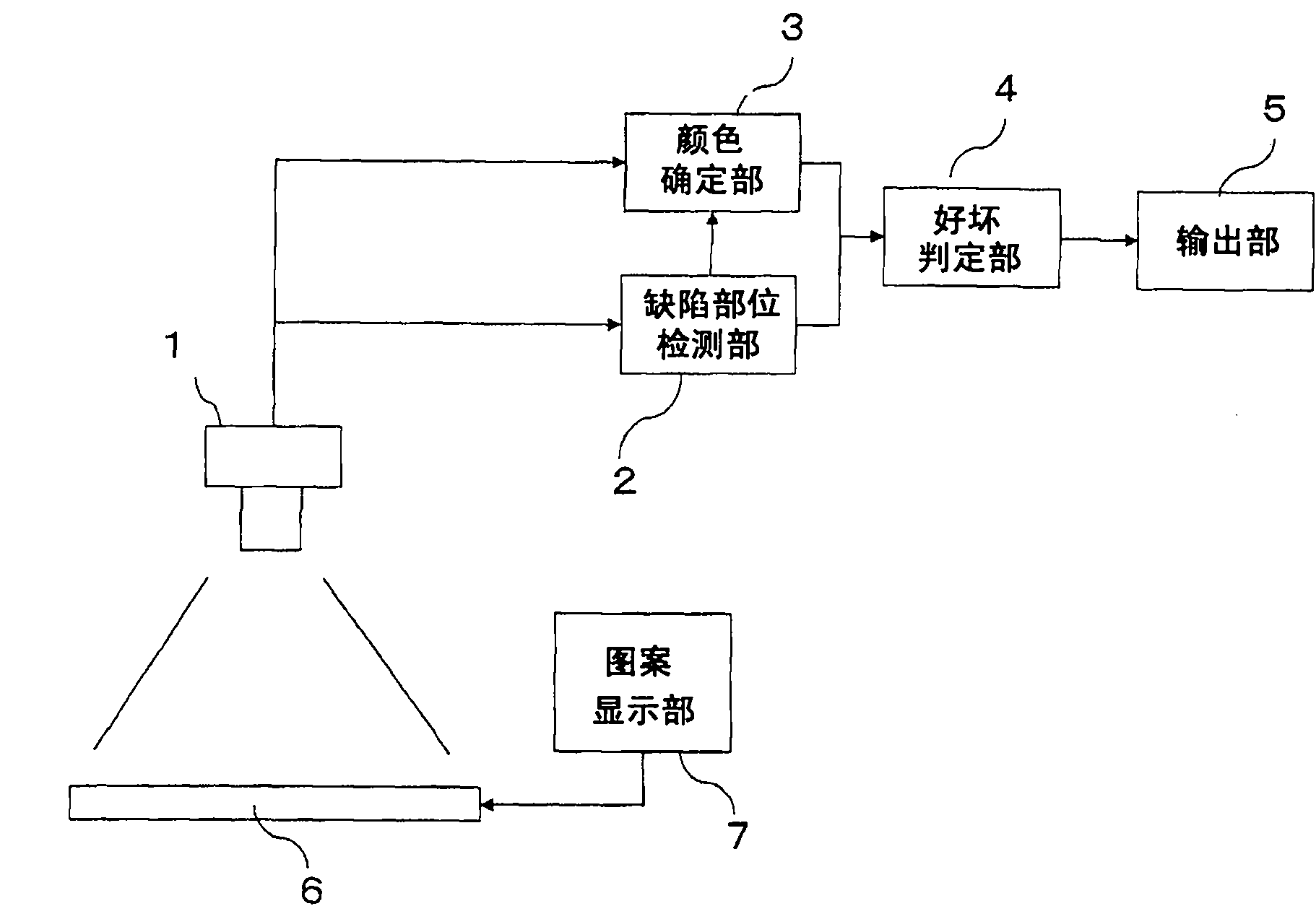

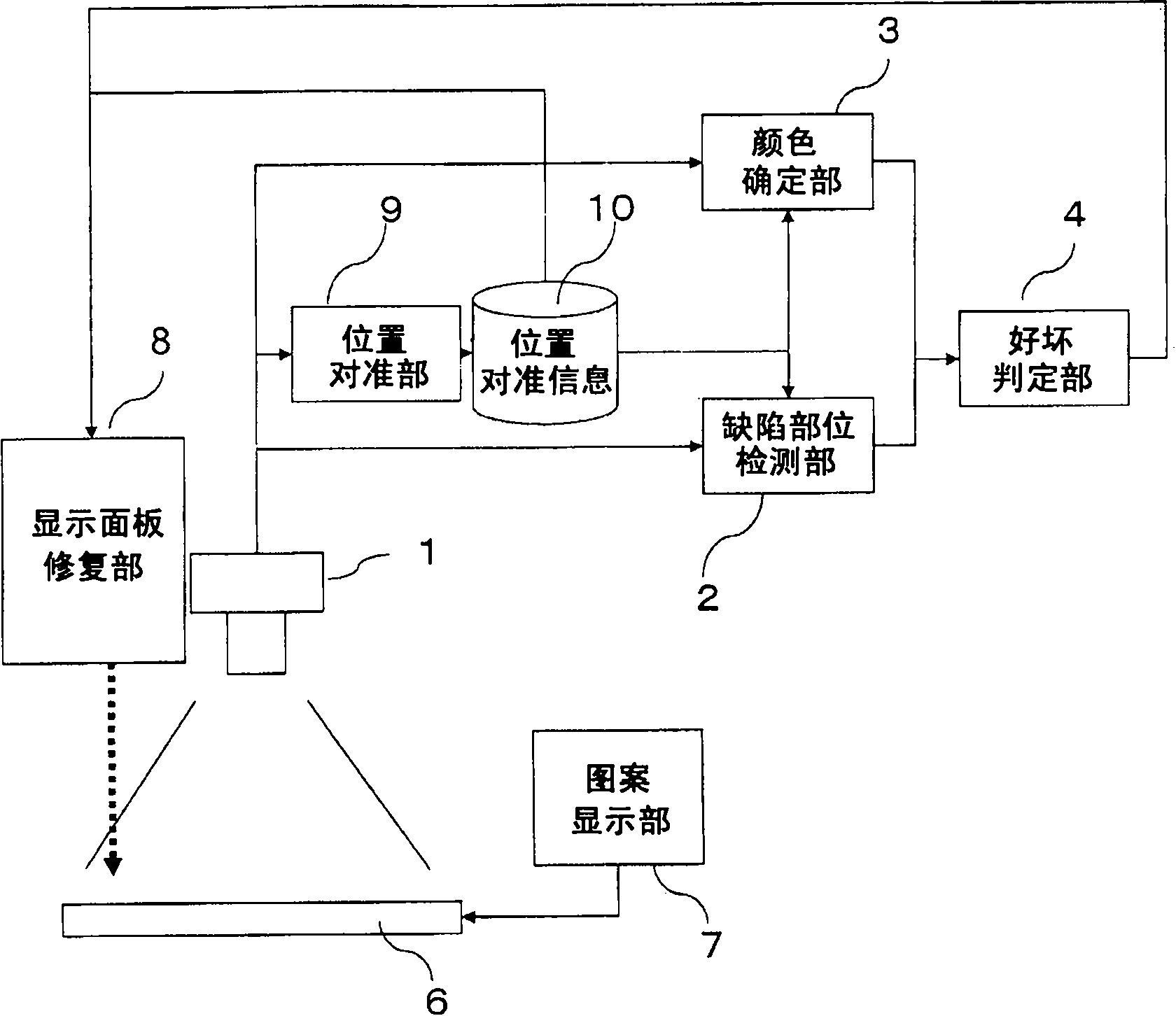

[0047] refer to image 3 , the structure of the defect repairing device according to the embodiment of the present invention will be described. image 3 It is a configuration diagram of a defect repairing device according to the present embodiment and a display device which is an object of defect repairing. The defect repairing device of this embodiment is a device for repairing defects (missing image elements, etc.) of a display device.

[0048] The defect repairing device of this embodiment includes the defect detection device according to this embodiment. Specifically, it includes an imaging unit 1 , a defect detection unit 2 , a color determination unit 3 , and a quality determination unit 4 . Moreover, it is comprised including the display panel repair part 8, the alignment part 9, and the alignment information 10. Moreover, the display device which is the target object of defect detection includes the display panel 6 . The pattern display unit 7 may be included in ei...

Embodiment 2

[0086] The present example is an example in which the calculation method of the step S5 of calculating the degree of defect is different from that of the first example. Other than that, since it is the same as in Example 1, description will be omitted.

[0087] refer to Figure 9 , and an example of calculation of the defect degree according to the present embodiment will be described. Figure 9 The corresponding relationship between the image element arrangement 100 and the pixel arrangement 101 obtained by photographing the image element arrangement 100 is shown in . The relationship between the picture element arrangement 100 and the pixel arrangement 101 is the same as that of the first embodiment. Furthermore, a contrast value 102a corresponding to the pixel arrangement 101 is shown. The contrast image 102 a is based on image data captured by displaying a solid black pattern on the display panel 6 .

[0088] Figure 9 The contrast value of 102 indicates that one defe...

Embodiment 3

[0106] This embodiment is an embodiment different from the embodiment 1 in the calculation method of the step S4 of specifying the color of the image element of the imaging pixel among the defect candidates. Other than that, since it is the same as in Example 1, description will be omitted.

[0107] use Figure 10 , Step S4 related to this embodiment will be described. In this example, something like Figure 10 Like the color 101a of the pixels x2, x4, x6, x8, and x10 shown, when one pixel includes (corresponds to) two or more image elements, the area ratio of each image element in the pixel is regarded as 1:1.

[0108] Although the method similar to Example 1 was used in the process after process S5, since the color 101a of a pixel differs from Example 1, the defect degree different from Example 1 was calculated.

[0109] by Figure 10 The calculation of the defect degree of x4 shown will be described as an example. First, the contrast value for each color when controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com