Uniaxially electrostatic-driven sensor for weak magnetic field measurement

A measurement sensor and electrostatic drive technology, applied in the field of sensors, can solve the problems of unfavorable magnetic field resolution, low modulation depth, time-consuming and laborious, etc., and achieve the effects of simple structure, reduced production cost, and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

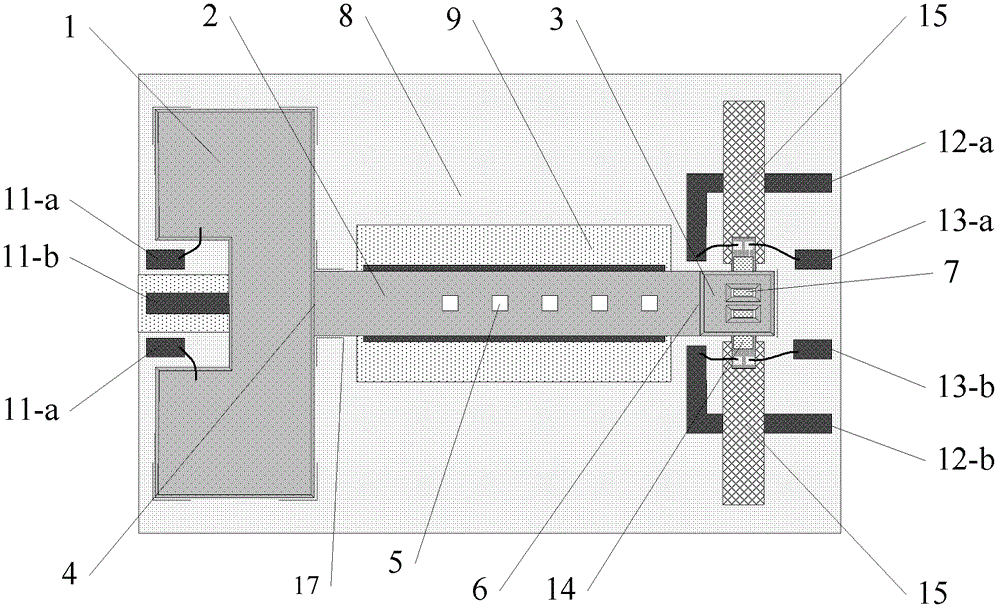

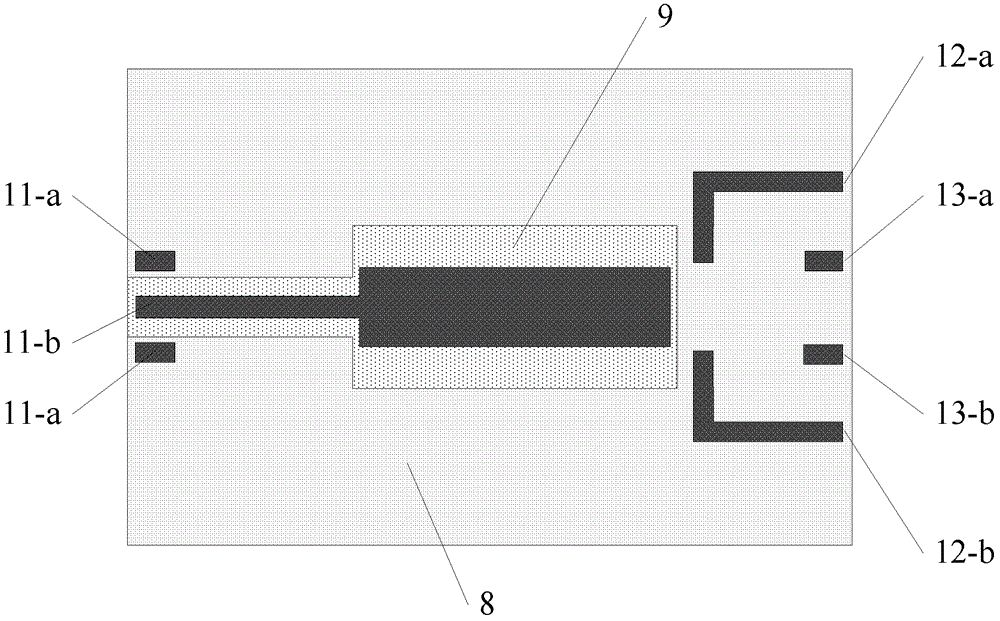

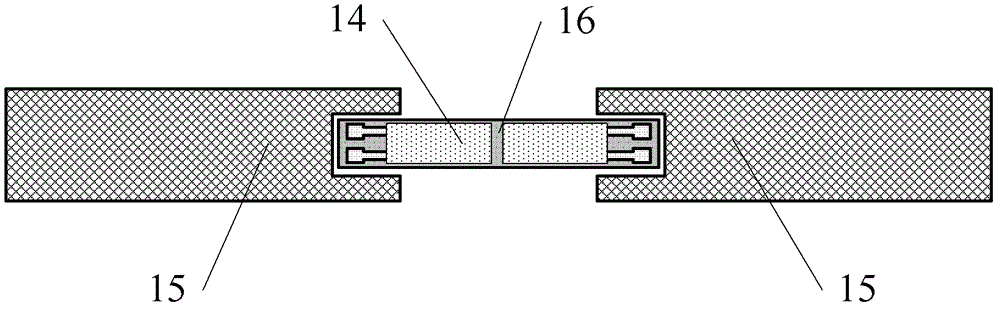

[0015] The present invention will be further described below in conjunction with accompanying drawing.

[0016] figure 1 It is a schematic structural diagram of a single-axis electrostatic drive weak magnetic field measurement sensor provided by a specific embodiment of the present invention. As shown in the figure, this specific embodiment includes an insulating substrate 8, a pair of electrostatic drive electrodes 11-a and 11-b, two pairs of input and output electrodes 12-a and 12-b, 13-a and 13-b, GMR sensitive Element 14, two identical magnetic field line concentrators 15, micro-cantilever beam 17, modulation film 3 (see Figure 4 ). The insulating base 8 adopts a glass sheet with surface polishing, and the glass sheet is coated with two pairs of input and output electrodes 12-a and 12-b, 13-a and 13-b, and a pair of electrostatic driving electrodes 11-a and 11-b; A shallow groove 9 is etched in the center of the insulating substrate 8, and one end of the shallow groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com