Capacitive type isolated bus with two shielded ends

An insulated bus, capacitor type technology, applied in the direction of insulators, insulated conductors, insulated cables, etc., can solve the problems of high production cost and complex process, and achieve the effects of low cost, avoiding short circuit between phases, and simple installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

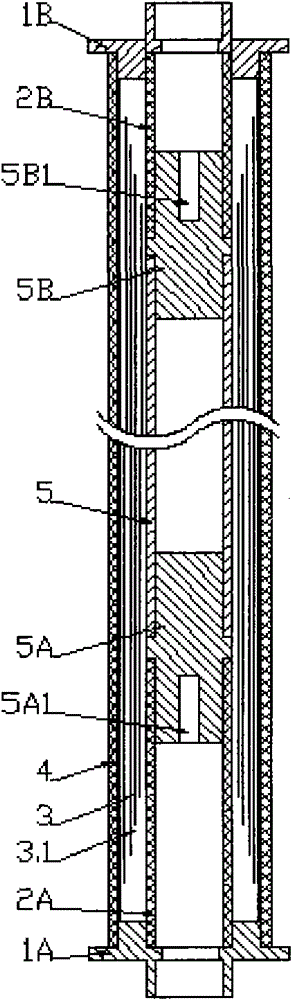

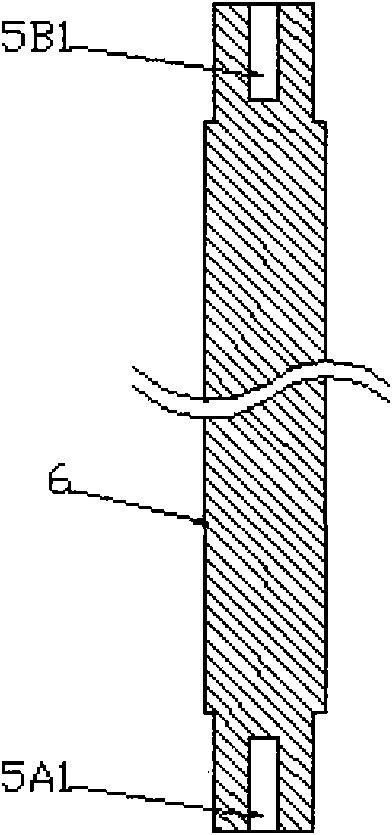

[0013] figure 1 is a structural schematic diagram of the first embodiment of the present invention, figure 1 As shown in the figure, in this embodiment, the double-ended shielded capacitive insulated bus bar mainly includes a guide body 5, rigid insulating cylinders 2A and 2B, fixed flanges 1A and 1B, and a capacitive insulator 3. It is characterized in that the guide body 5 is arranged on The center position and the two ends of the guide body are provided with plug-in terminals 5A and 5B with slots 5A1 and 5B1. The two ends of the guide body 5 are respectively connected and fixed to the rigid insulating cylinders 2A and 2B, and the other ends of the rigid insulating cylinders 2A and 2B are fixed. One end is respectively fixed on the fixed flanges 1A and 1B, and the socket ends 5A and 5B are provided with socket slots 5A1 and 5B1, and the rigid insulating cylinders 2A and 2B and the outside of the guide body 5 are provided with organic insulating tapes. The capacitive insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com