A cable mold

A cable and mold technology, applied in the field of cable molds, can solve the problems of high manufacturing cost, long process consumption time, complicated manufacturing process, etc., and achieve the effect of fast production speed, less material consumption and reduced process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

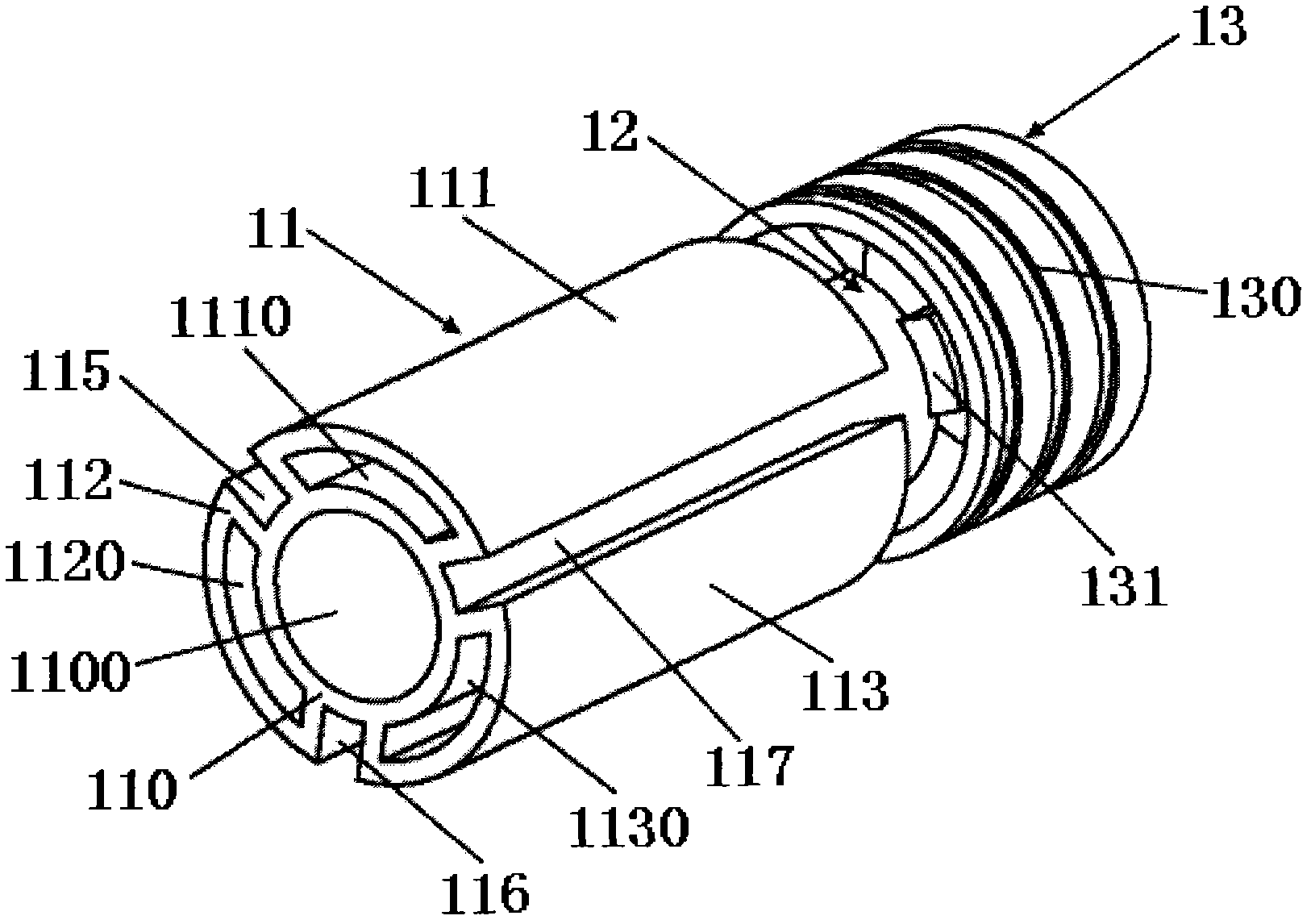

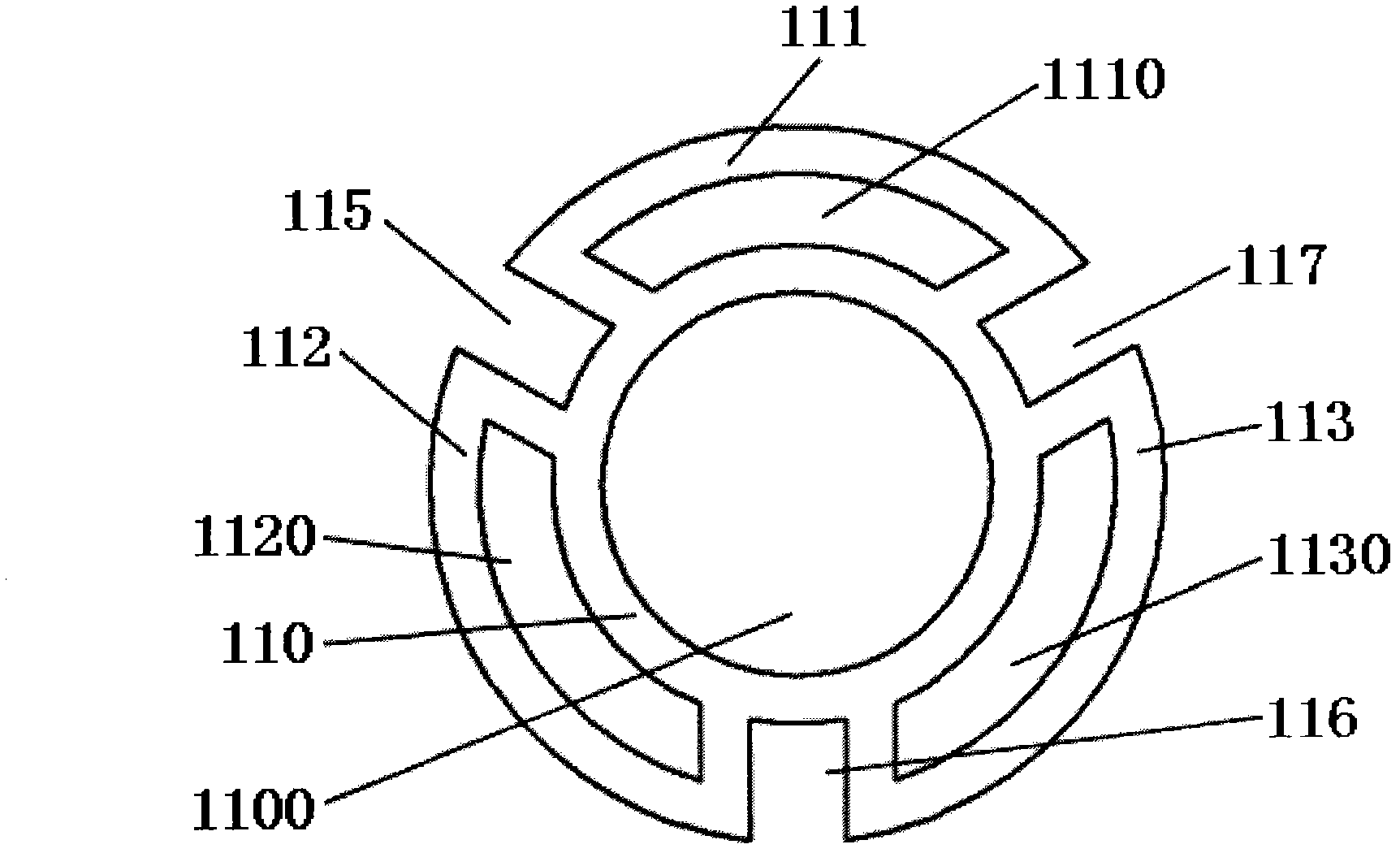

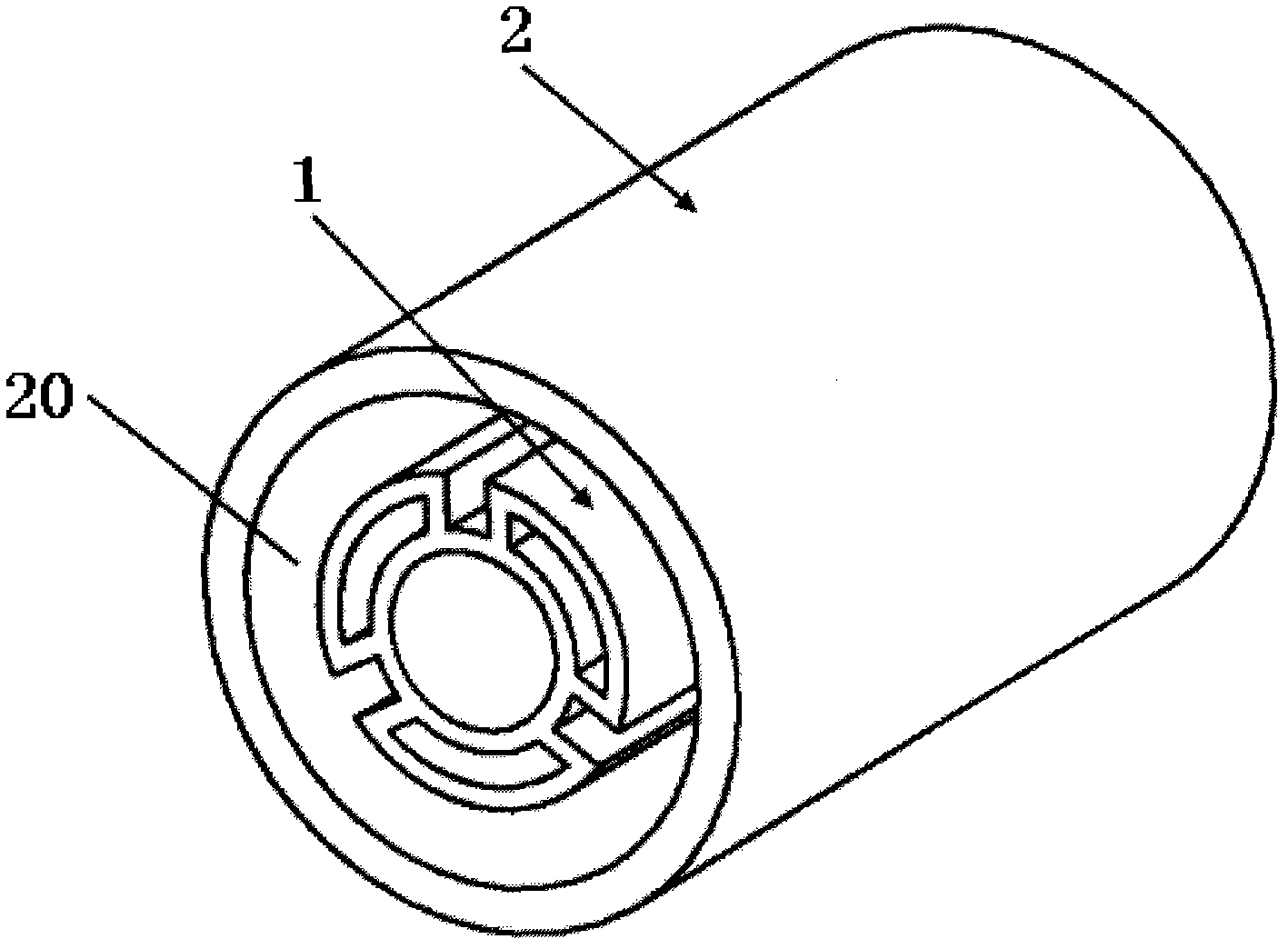

[0022] please see Figure 1 to Figure 4 , a cable mold, including a mold core 1, a mold cover 2, characterized in that the mold core is composed of a molding part 11, a transition part 12, and a connecting part 13, the molding part is located at the front end of the mold core, and the transition part is located at the middle end of the mold core , the connection part is located at the rear end of the mold core; the molding part is composed of three conductor guides (111, 112, 113), three spacer strips forming channels (115, 116, 117), and a filler guide 110, and The number of channels formed by the conductor guiding device and the spacer is equal. The conductor guiding device 111 contains a conductor hole 1110 inside, the conductor guiding device 112 contains a conductor hole 1120 inside, and the conductor guiding device 113 contains a conductor hole 1130 inside. The interior of the device contains a filling body hole 1100, the filling body guiding device is located in the cen...

Embodiment 2

[0025] please see Figure 5 and Figure 7 , and refer to Figure 1-4 A cable mold, comprising a mold core 1 and a mold cover 2, characterized in that the mold core is composed of a molding part 11, a transition part 12, and a connecting part 13, the molding part is located at the front end of the mold core, and the transition part is located at the middle end of the mold core , the connecting part is located at the rear end of the mold core; the molding part is composed of two conductor guiding devices (111, 112), two spacer strips forming channels (115, 116), and a filler guiding device 110, and the conductor guiding device and The number of channels formed by the spacers is equal, the conductor guiding device 111 contains a conductor hole 1110 inside, the conductor guiding device 112 contains a conductor hole 1120 inside, the filling body guiding device contains a filling body hole 1100 inside, and the filling body guiding device is located at the molding The filler body h...

Embodiment 3

[0028] please see Figure 6 , and refer to Figure 1-4A cable mold, comprising a mold core 1 and a mold cover 2, characterized in that the mold core is composed of a molding part 11, a transition part 12, and a connecting part 13, the molding part is located at the front end of the mold core, and the transition part is located at the middle end of the mold core , The connection part is located at the rear end of the mold core; the molding part consists of four conductor guides (111, 112, 113, 114), four spacer strips forming channels (115, 116, 117, 118), and a filler guide 110, and the number of channels formed by the conductor guiding device and the spacer is equal, the conductor guiding device 111 contains a conductor hole 1110 inside, the conductor guiding device 112 contains a conductor hole 1120 inside, and the conductor guiding device 113 contains a conductor hole 1130 inside , the conductor guiding device 114 contains a conductor hole 1140 inside, the filling body gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com