Liquid crystal display device

A liquid crystal display device and liquid crystal layer technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as large limitations, blurred text, and reduced brightness, and achieve the effect of moiré interference suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

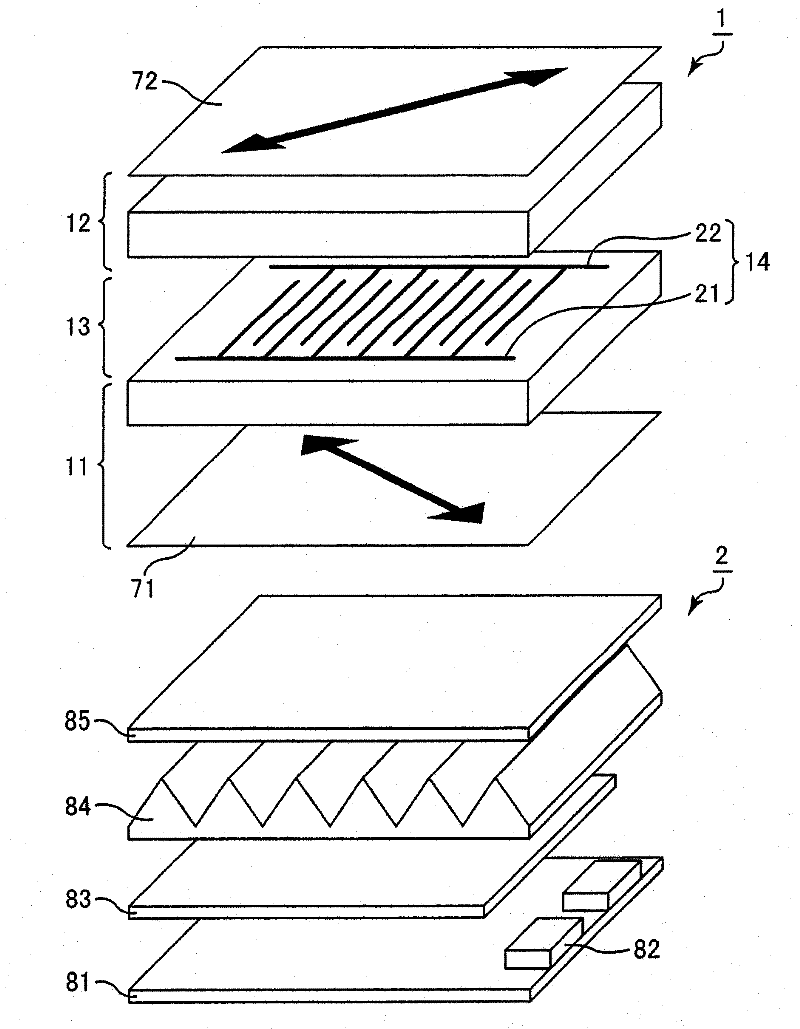

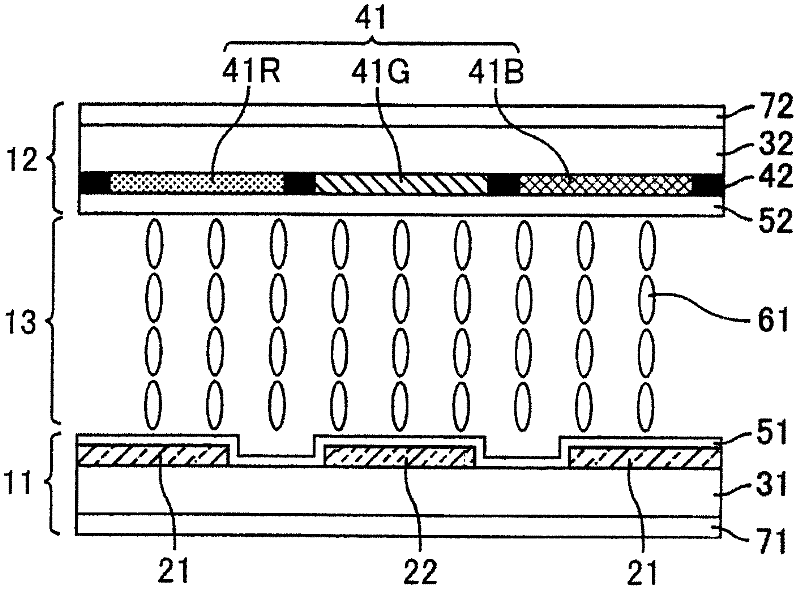

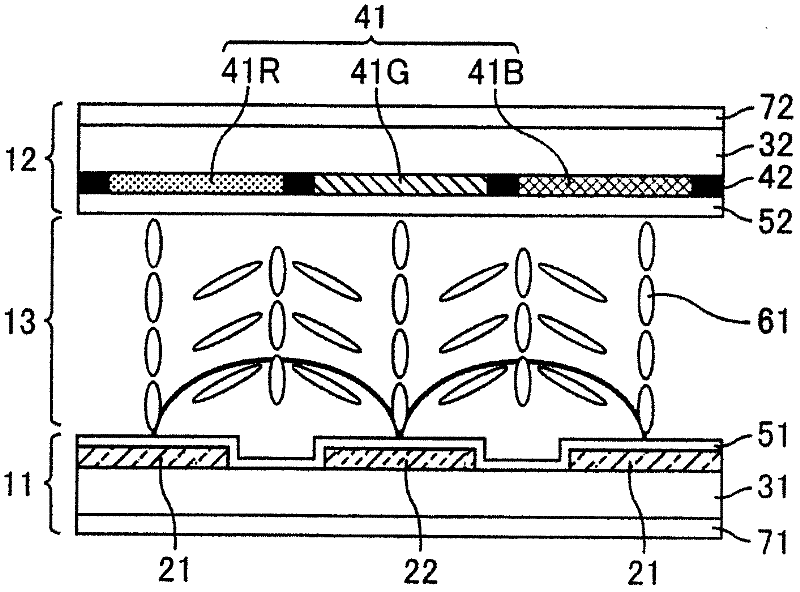

[0065] figure 1 It is a schematic perspective view of the liquid crystal display device of the first embodiment. The liquid crystal display device according to Embodiment 1 includes a liquid crystal display panel 1 including a liquid crystal layer 13 and a pair of substrates 11 and 12 sandwiching the liquid crystal layer 13 . More specifically, the liquid crystal display device of Embodiment 1 has these components in order from the back side toward the observation side, in the order of the TFT substrate 11 , the liquid crystal layer 13 , and the counter substrate 12 . The liquid crystal layer 13 contains a nematic liquid crystal having positive dielectric constant anisotropy (Δε>0). Furthermore, the liquid crystal display device according to Embodiment 1 includes a backlight unit 2 on the rear side of the liquid crystal display panel 1 .

[0066] Such as figure 1 As shown, the TFT substrate 11 in the above pair of substrates has a pair of comb-shaped electrodes 14 whose com...

Embodiment 1

[0092] Figure 7 It is a schematic plan view of the sub-pixel unit in the display area of the liquid crystal display device of the first embodiment. First, a pair of glass substrates is prepared, and an ITO film is formed on the entire surface of one of the glass substrates by sputtering. Next, a pair of ITO products with a width (electrode width) L of the lines 91 of the comb teeth of 2.5 μm and a width (electrode spacing) S of the intervals 92 between the comb teeth of 8 μm (that is, a pitch width P of 10.5 μm) were produced by photolithography. Comb electrodes.

[0093] Next, alignment film JALS-204 (5 wt %, γ-butyrolactone solution) manufactured by JSR Co., Ltd. was applied by spin coating on the comb-shaped electrodes and the glass substrate, followed by firing at 200° C. for 2 hours.

[0094] Next, on another glass substrate, a BM having a width of 10 μm, a length of 100 μm in the lateral direction, and a length of 300 μm in the vertical direction was formed, and an ...

Embodiment 2

[0100] Figure 8 It is a schematic plan view of the sub-pixel unit in the display area of the liquid crystal display device of the second embodiment. The liquid crystal display device of Example 2 was fabricated as follows: the width (electrode width) L of the lines 91 of the comb teeth was 2.5 μm, and the width (electrode spacing) S of the interval 92 between the comb teeth was 5 μm. It has the same structure as Example 1 except that the pitch width P is 7.5 micrometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com