A method for separating and filtering molecular sieve crystallization slurry

A separation filtration, molecular sieve technology, applied in separation methods, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of high concentration of triethylamine, grain pollution, aggravated plate and frame filter cloth and equipment corrosion, etc., to achieve separation efficiency High, simple operation, reducing pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

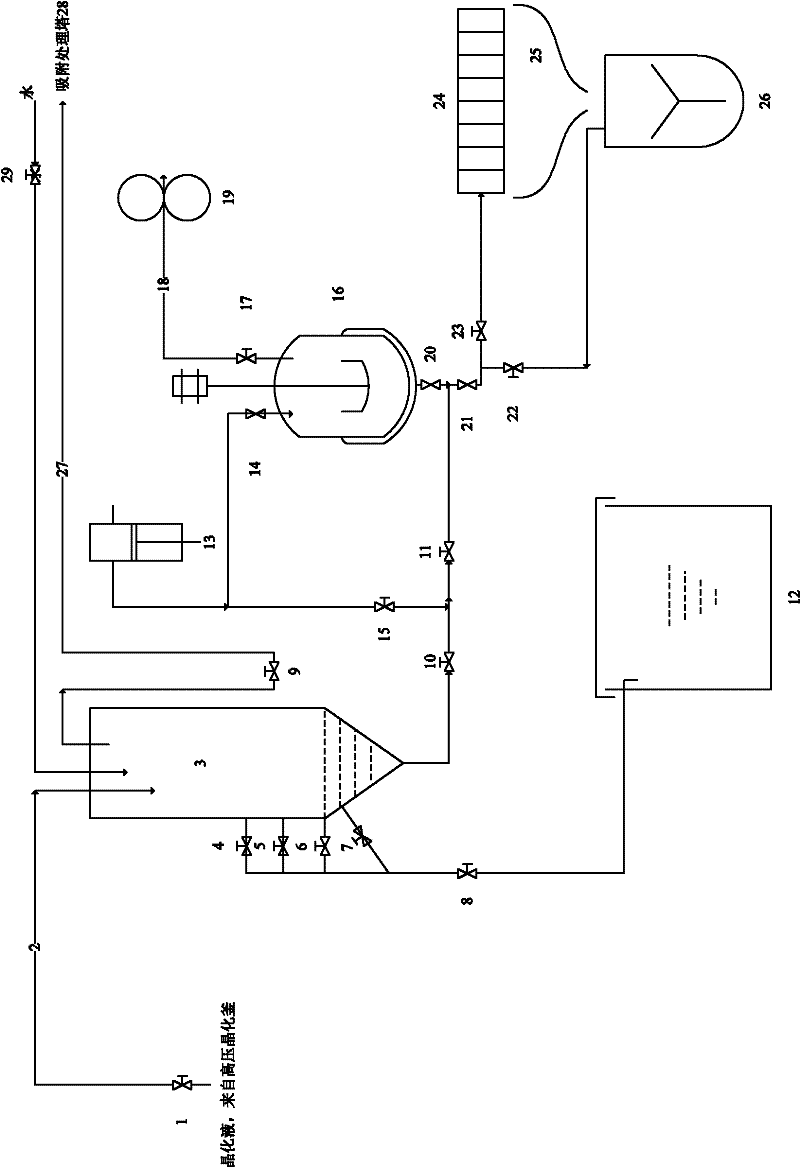

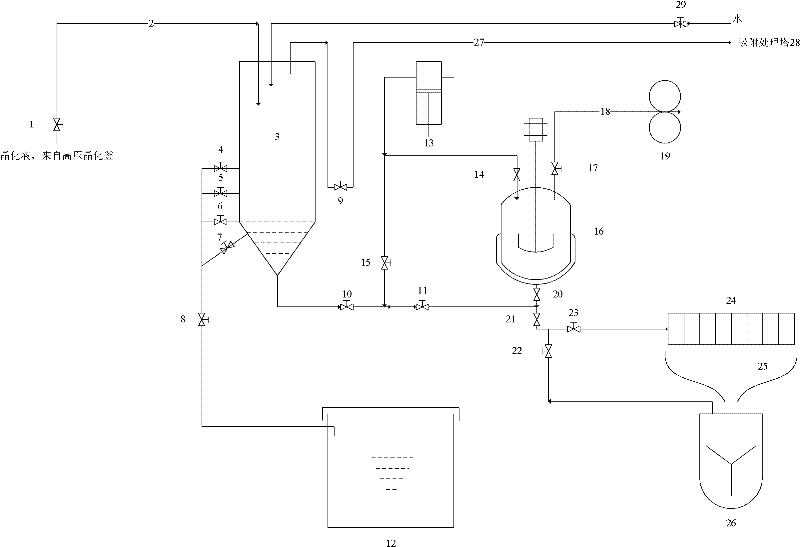

[0110] This embodiment is an application of the process flow provided by the present invention in the industrial production of SAPO-34 molecular sieve, but the protection scope of the present invention is not limited to the content described in this embodiment.

[0111] The SAPO-34 molecular sieve industrial production device is composed of a synthesis unit and a separation unit. The synthesis unit performs the crystallization synthesis of SAPO-34 molecular sieve; the separation unit performs the solid-liquid separation and washing process of the crystallization slurry. After the SAPO-34 molecular sieve is crystallized and synthesized, it enters the separation unit through the unloading valve unloading 1 and the unloading pipeline 2. The specific steps are as follows:

[0112] 1. Check the entire process valve to make sure that they are all closed.

[0113] 2. Unload the crystallization slurry to the discharge settling tank 3: After the crystallization is completed, open the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com