A hot-rolled h-shaped steel finishing roll die and hot-rolled h-shaped steel processing technology

A processing technology and finishing roll technology, which is applied in the direction of rolls, metal processing equipment, metal rolling, etc., can solve the problems of inability to adapt to large-scale, integrated production, low efficiency of H-shaped steel, and low bearing capacity, so as to overcome the processing efficiency Low, improve production efficiency, improve the effect of structural performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

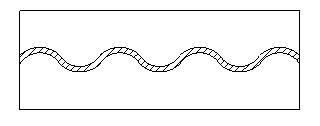

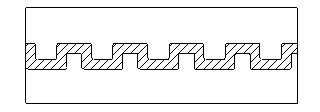

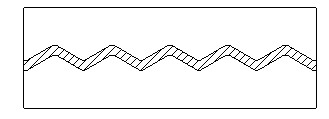

[0022] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. In order to complete the production process of this hot-rolled H-beam, a new type of roll profile is adopted on the finishing roll of the finishing mill. Corresponding curve line segment, this kind of curve line segment can be one of arc line, hyperbola, parabola, ellipse line, or one of "П" line segment, "v" line segment or "︹" line segment, Using different curves or line segments, hot-rolled H-shaped steel with different cross-sectional shapes can be obtained. When the curve is used to form the finish rolling roll mouth, the corrugated web H-shaped steel is processed. When the "П" line segment is used to form the finish rolling roll mouth , to process rectangular web H-shaped steel, when the "v" line segment is used to form the finishing roll H-shaped steel, the triangular web H-shaped steel is processed, and when the "︹" line segment is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com