Automatic Loading Device in Body Welding

An automatic and body technology, applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of high labor intensity, difficulty in ensuring the accuracy of workpieces, hidden safety hazards, etc., to ensure welding quality, eliminate adverse effects, avoid The effect of accident hazard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

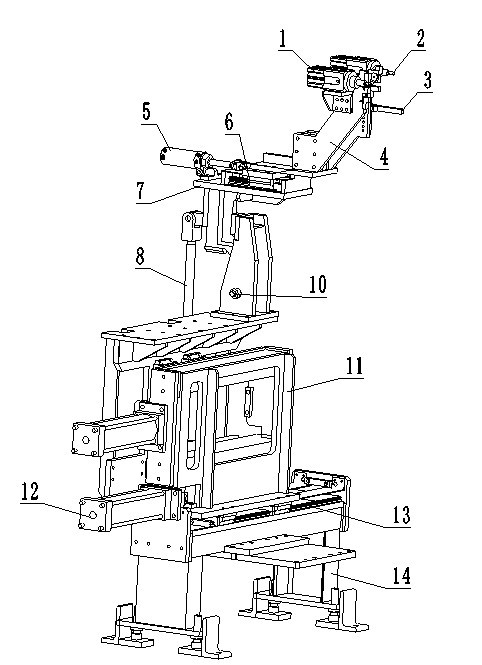

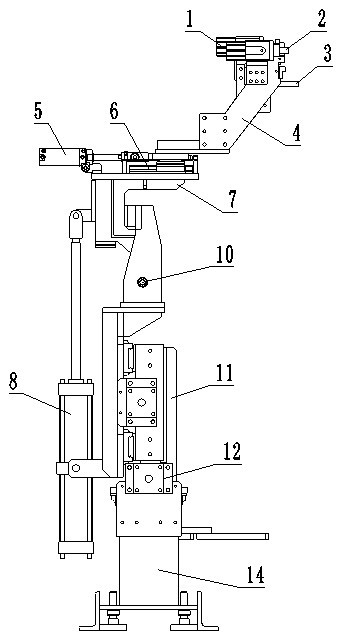

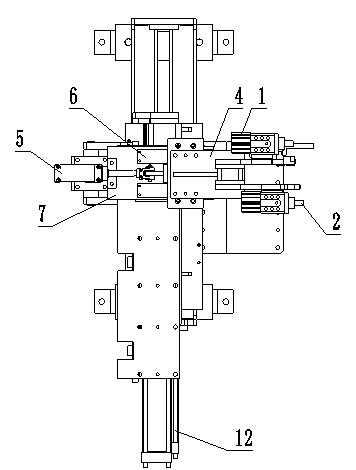

[0019] see Figure 1 to Figure 4 , the present invention consists of a workpiece holder (including a clamping cylinder 1, a workpiece positioning pin 2 and a clamping hook 15), a workpiece support 3, a holder bracket 4, a propulsion cylinder 5, a propulsion slide rail 6, an overturn frame 7, an overturn Cylinder 8, turning shaft 10, slide table 11, horizontal positioning cylinder 12, lateral slide rail 13 and fixed seat 14 form.

[0020] The workpiece holder clamps and positions the workpiece during the overturning and welding process; the propulsion cylinder 5 can push the workpiece forward after overturning, so that the workpiece fits the body; the overturning cylinder 8 is used to control the overturning frame 7 and the workpiece holder on its upper part Holder and other components can be flipped over, and the workpiece received from the feeder can be turned over to a vertical state; the horizontal positioning cylinder 12 can push the slide table 11 to move along the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com