A complete set of waste plastic recycling, crushing and cleaning equipment

A complete set of equipment and waste plastic technology, applied in the field of waste plastic recycling devices, can solve the problems of lack of efficient and coordinated circuit design and control center, poor production site environment, scattered control interface, etc., to achieve clean production and low power consumption , the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection claimed by the present invention is not limited to the description scope of specific embodiments.

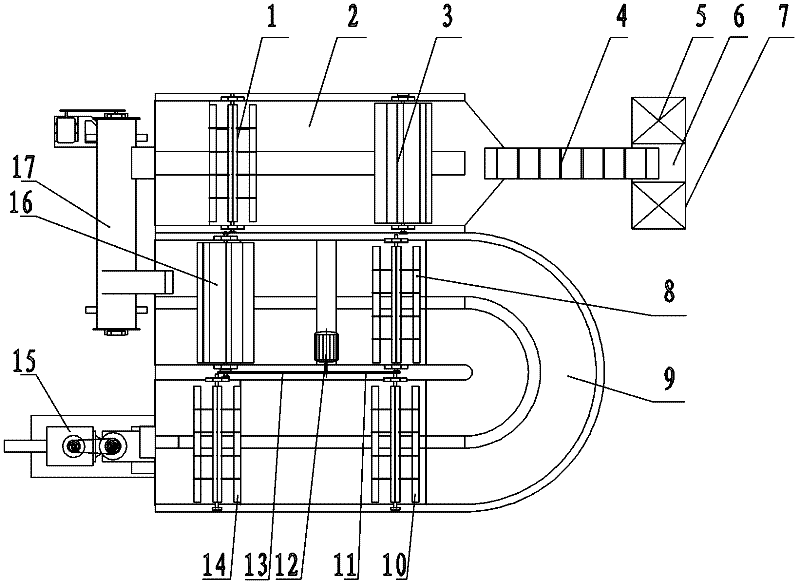

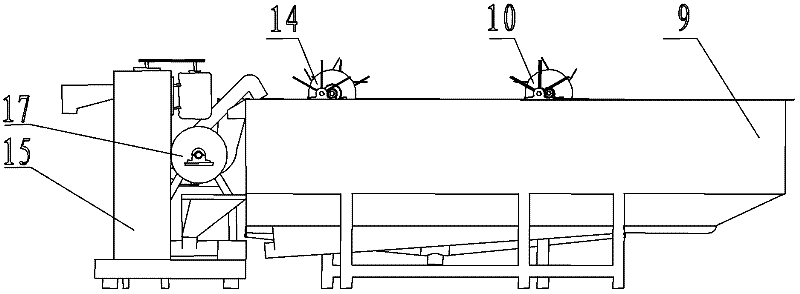

[0028] As shown in Figures 1 and 2, a complete set of waste plastic recycling, crushing and cleaning equipment includes a first plastic crusher 5 and a second plastic crusher 7, a debris pool 6, a debris elevator 4, a first bulk material roller 3, a first Pool 2, first driving roller 1, horizontal dehydrator 17, second bulk roller 16, second driving roller 8, second pool 9, third driving roller 10, first chain 11, gear motor 12 , the second chain 13, the fourth drive roller 14 and the vertical dehydration dryer 15.

[0029] The horizontal sections of the first pool 2 and the second pool 9 are rectangular and "U" shaped structures, and the longitudinal sections are square or "U" shaped structures; the first pool 2 and the second pool 9 are arrang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com